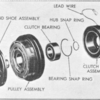

The York compressor clutch does not use shims to set the air gap. It is set by design. To remove the clutch and pulley assembly, remove the bolt and washer in the center of the clutch hub. Using a 5/8" coarse bolt, screw it into the center of the clutch hub until it bottoms on the compressor crankshaft nose. Continue tightening until the hub is loose. If you don't have the three point spanner to keep the hub from rotating, energize the compressor clutch (with the belt still attached) and tighten the bolt. Or wrap the belt around the pulley and hold with your hand. You can also "bump" the bolt with an impact gun. The nose of the compressor crankshaft is tapered, so you only need to "break" it free.

Another possibility is that the clutch coil (the part that has the wire connection) may not be centered inside of the pulley. You can try loosening the four attaching bolt and see if the pulley becomes free. This usually isn't the problem, but it has happened.

John

PANTERA INTERNATIONAL

A DE TOMASO CAR CLUB

Presents the De Tomaso Forums

The On-Line Meeting Place for De Tomaso Owners and Enthusiasts From Around the World

Clicking on the banner will take you to the sponsor's website.