I shouldn't, but I can't help myself at time. Actually, I got lost in the exchange so don't know what to reply to

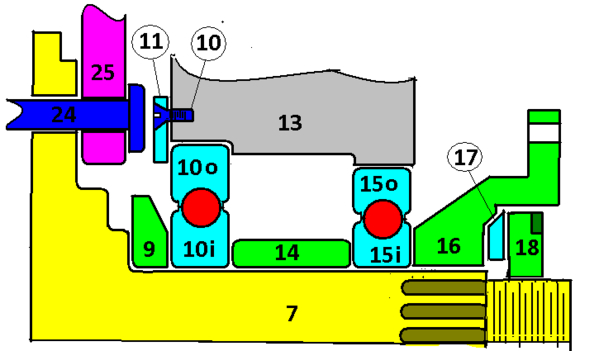

this assembly does not preload the bearing (like with front taper)

the nut is to make the inner two races (10&15) one with the axle (7)

the threads are a 1 3/8" bolt thus a "normal" torque for a cheap bolt would be ver 400 ft-lbs. (almost 3X)

In my previous life (back when I knew how too) Verify bolt torques use to be one item I had to calc. the reduce outer diameter of the locknut versus a normal bolt head will reduce to required torque somewhat. (I just don't fell like calculating anymore)

the locking washer (installed between 17&18) would have no compression, thus a solid washer as the outer tabs are outside the nut face.

Tired now and going to take a knap!

edit. . couldn't sleep

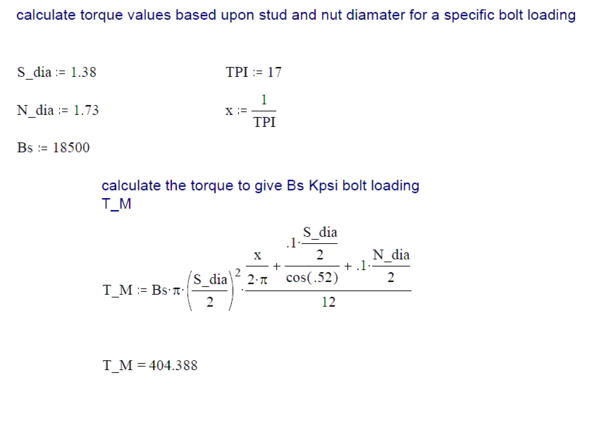

a quick run through a MathCad routine I used for land base turbine bolting

I played around with the Bolt Strenght value to see what the threads would be loaded to at 400 ft-lbs. Note a cheap bolt would have a strenght of 60kpi.