After 35 plus years, the shell of 5177 was rolled from its shed and is on its way to GunnerZ along with a trailer of parts.

The Owner and a couple employees drove 4 hours early this morning and loaded 5177 for the return trip to the shop.

Replies sorted oldest to newest

Another rescue begins. Well done

Congrats! That's a big step!

Looks cool with that DT trailer!

Rocky

Hope you'll share progress reports!

Awesome!

That's great news!

They don’t look like pantera parts. Maybe they’re from his tractor.

They might be left over from your Spitfire, or your TR-6.... I haven't seen anything like them.

Rocky

as for those 3 pieces, I am wondering if the tech doing the inventory threw them in as a test ![]()

Just knowing it is no longer under my shed feels better.

What color are you thinking of painting it?

I want a driver. the paint selected for ease of repair in the the future, hopefully from Ford colors.

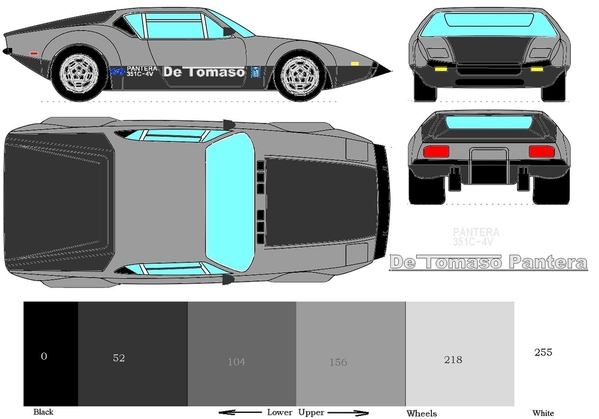

those colors are to be in the GT Scheme of "Shades of Grey"! the upper being near silver and the lower a near black. with a decal in the lower section.

As far as the build, It will be near original with the exception of modern AC!

The builder and I disagree on one item so far. I requested use original harness and modify it for the changes I want. Where he suggested and wants to use a modern harness.

Comments requested as to whether or not.

another disecion is whether to go back with L bumpers or fill in the body holes and go with the polish stainless I purchased. While I think the look is better, the ideal that they are just bolt on trim is concerning. the Builder wants to see what he can do to make them functionaly as bumpers.

Again, comments requested

I am sure there were be lots more request for comments as the work progresses

Great to see they jumped right in with the stripping. New wiring is great, but costly as it is time consuming. Maybe, if he will commit to a price for that part of the job, it could help you decide. I cannot imagine making the body fit bumpers Functional in any way, but they look a lot better than the 74 bulk. These bumper are the Amerisport .

I am seeking ideals on what items need, or could be done to the body when it is on the rotisserie.

That's great that the shop you chose is making such good progress. At this pace there is no doubt your car will be finished before mine.

My first thought is to address all drain holes and add the drain holes others with more P-car knowledge have suggested in previous posts. Next I would inspect the undercarriage for any hidden rust pockets and its integrity. Make sure that all tabs, brackets and anything else is there and the way you want it. It's easy to overlook the detail and later have to do some grinding and welding after paint.

I would have a serious discussion with your body shop professional about hidden areas and rust proofing or paint or whatever is appropriate to keep you car from rusting later on. It really is sad to see a beautifully painted car have rust poke through in a year or two after the "restoration".

Another thing to check for is damage. It's not unusual for low sports cars to have undercarriage damage from running over something. Perfect on top, dented on the bottom.

I'm only about half hour from your body shop. I would be happy to meet you there during one of your visits to meet and chat a bit.

thanks Mike, that is what I am looking for.

just to mention, I didn't chose this shop, the Owner heard of my situation from his family member that does some grounds work for me. So that is why a shop not that familair with Panteras is doing my car.

I sure wish I could met you there, but I doubt if I will even go to the shop. I have just emailed the Owner about his policy on visitors, so I need to here back form Him first, but having someone checkup on the car would be GREAT!

Here is the initial list I gave Him about what I wanted. while I think it is just an outline for farther discussions, he said that was more than most the car owners give him

That is quite a list.

Hi JFB -

(Not having read your list - yet...)

My suggestions might be:

1. Reinforce all Jack Points, especially the one at the back of the car (the box beam that terminates the frame). There is a standard size rectangular bar that fits right in there, see one of the early pages of my 5357 thread.

- JFFR reinforced his forward jack points, and tied these into a stiffening system of his own design to provide a stiffer frame, without the wacky stiffening kit that takes up the room in the luggage compartments.

2. Seam weld the car, at least in areas that supply structural stiffness. This can be a big project, but your car is in the state where it can be done.

3. Improve / strengthen suspension mounting points - like "Push1267" did on his Group 4 car over there in Denmark.

4. Check the areas of the car in front of the engine compartment bulkhead on either side. There is a big hole where debris can get in on either side of the engine bay front bulkhead, and the debris lays right agains a single thickness body panel.

5. Drop the battery below the front trunk onto the steering rack - you fabricate a tray and a door for it.

Rocky

thanks,

here is Push's post

https://pantera.infopop.cc/top...ilding-a-gr4-replica

I'll be studing that one for a WHILE, there is a LOT of info there. Given "I" will not be driving hard, need to weight cost to have it done versus benifit

Nothing to report nor new photo's to share. the biggest activity (as far as I know) has been the transfer of funds to cover man-hours for paint removal and some body work!

the recent communication was asking about frame modes for jack plates. I wrote the following notes and emailed to shop.

...That's quite a Plan! I Think You Covered Everything. Gonna take Awhile. Good-Luck with it! It Will Be Fun!

To add a little Note...on the '74 Pantera, the Factory Fuel Gauge, Already has a RED Light Built Into the Face. It Comes ON at Aprox. 30 Miles of Fuel, Left. 'About' 2 Gallons, by My Experience.

MJ

thanks MJ for reviewing my INITIAL plan. My agreement with Billy (paint shop owner) is that nothing is really a MUST, so I listen a lot to what He suggest.

As for the details of the dash/instrument panel, I've had some new thoughts, but holding off in providing to him until he gets there in the rebuild. instead of trying to add warning lamps near the guage, maybe put them between the tach and speedo, where the original "brake" warning lamps were. Not sure about keeping brake warning anyway

I am thinking of moving the wiper switches to under the window switches in the center panel. Deleting the "courtesy lamp" and "manual radiator fan" switches. I would also expect the HVAC fan switch will be part of the modern controls that will be on the passenger side of the center section

While it's on a rotisserie, now is the time to address strengthening the chassis. The following are good to do even for a street driven car, otherwise you will experience cracking in your new paint at all the usual locations - base of the front A-pillers adjacent to the windshield, y-area curve at the top of the rear quarter decklid opening, and outside lower corners at the tail lights...

Seam-weld the entire car. Once stripped, you'll see in the engine bay that all the panels are merely spot welded together. Many have found when restoring their cars that a number or the spot welds have let go over the years, further contributing to body flex and cracking. Welding these seams will significantly strengthen the entire chassis/structure of the car.

Also, weld in 18 gauge doublers at the key locations where the body tends to crack...

More info on this thread: https://pantera.infopop.cc/top...783#1598208420462783

I've been told that Dennis Qualla in Colorado sells the aforementioned body doublers. Other vendors may have them as well.

Regardless of whether you intend to drive the car hard or not, simply going in and out of driveways subjects the car to substantial body twist/flex and will lead to cracking. These mods help prevent that.

Anyway, keep the pics and updates coming!

update

the seams have been stitch welded and the "jacking plates" installed

a floor jack plate across the rear cross member (will be drilled in the center for the tire jack peg)

Not sure about the rear post jack arm position under the motor mounts

the center frame tire jack position

the front frame tire and post jack arm position

and added a front frame floor jack position (also will be drilled for tire jack plug)

That looks good, Joe -

I use that front jack point a lot - I use a 2x4 that fits precisely in there, I would love to have a permanent jack point like you've now got.

I don't know if I'd waste (much) time drilling the front or rear to accept the hand crank jack - If you're at home, you use your floor jack, and on the road, you pull out your AAA card!

Rocky

So the body was good, without rust?

What's next?

Looking good JFB, I agree with Garth 100% on the extra plates on the tail lamp outer edges and tops of the roof B pillars. Mine all cracked back after a few years.

So any pictures of the reinforcements around tail light corners? I'd like to see how they are located.

transsami posted:So any pictures of the reinforcements around tail light corners? I'd like to see how they are located.

Me Too! or even a marked up photo on exactly where they go

Here are a few other links on the subject...

https://pantera.infopop.cc/topic/body-supports

https://pantera.infopop.cc/topic/body-reinforcements

Also, you may want to reach out to Mike Drew for some pics...

Thank you for the links.

What I'm looking for is that where are those supposed to be welded. I don't see any possible way to do it from the inside. So are they welded on the outside and just bondoed over?

-Sami

Love it. Cat on the rotisserie for Christmas.

after Holidays and shop vacation, we had an update call today.

Big thing was chosen paint. Shop had mailed me several painted "shell" based upon color I tried to describe. We both decided on a silver called "Forged Silver Metalic" and a near black called "Phantom Grey Metalic"

My engine builder seems like he will be a hold up.

an upcoming item we discussed was some changes to the dash layout I would like. that is mainly put the wiper/washer in the center console, use the right side center console for "vintage air" control and add idiot lamps for oil pressure and coolant temperture. I don't see a need for brake warning.

some update pics

Progress is being made! Congrats!

I little up date.

well, the local legionary Cleveland engine builder that had mine for a couple years told be to come and get the pieces as he was no longer able. this was a real disappointment. So I loaded up the pieces and took to the Car Builders shop (GunnerZ) about 4 hours away (Denver, NC.

given that GunnerZ location to all the NASCAR shops, I sure hope they can find an engine builder,

this was the first time I had visited GunnerZ but was impressed with organization and cleanliness.

what I gathered, there was work on all the pieces so assembly should start showing progress some. For example the suspension is on for fitup and comes off for final painting latte

I've lost interest but the shops manager seems to be agressive at finding info and parts. surprising though was they were waiting to get rear axle bearings due to covid related delays

When it comes to building a new Cleveland patience seems to be the most valuable item on the parts list.

When it comes to building a new Cleveland patience seems to be the most valuable item on the parts list.

I retrieved my block and components from the first engine builder when there had been absolutely no progress after 3-4 months.

My second engine builder finally delivered my engine to me after about one full year and I’m very glad I pulled a valve cover for inspection of the new roller rockers. See photo. 😳😡

That discovery prompted me to take it to my third engine builder with instructions to completely tear down the engine and check all clearances, and reassemble.

The third machine shop has a engine dyno along with a chassis dyno. The engine dino resulted in 454 hp with 475 foot pounds of torque.

Yours may also be a long journey but I hope your results are as good as mine were. 🤞🤞

Larry

Larry, what was the cause of that roller rocker being off, stud not in the head correctly?

Assembly laziness.

CHI 4V heads. ARP studs, Comp Cams guide plates and rocker arms.

The ID of the guide plates was slightly larger than the diameter of the studs and thus allowed the guide plates to be adjusted for correct, or incorrect, positioning.

I had cautioned the engine builder that guide plate alignment was often troublesome for assemblies like this and if necessary they are sometimes cut, properly positioned and then welded to retain correct alignment.

and yet he delivered the engine to me as pictured. 😡😡

The previous photo was the worst example of misalignment but not the only example.

The third shop found they were able to obtain correct alignment with judicious attention to correct alignment as allowed by the ID versus OD diameter differences.

Larry

I'm curious on how the car coming along. Any updates?

I am curious also and CONCERNED.

the excuse is COVID ! very little work (thus no invoices) since the "shut down"

Oh man, sorry to hear that. The extra wait must be excruciating. Hopefully they will be back at it soon. Will be worth the wait! I have plans on taking mine down this year for full restoration at some point. As to not clutter your thread, I may PM you with a few questions when I get there.

Check out Jon kaase racing engines. He is a big Ford engine builder. He also competes in the Engine Masters Challenge and has won many of them with different Ford engines.

I had a discussion with shop building 5177 last week. (I've lost interest

and relying his abilities.) Progress is VERRY slow

The engine builder that abandoned the project a couple years ago had found

"the" ford aluminum intake, in his opinion, better than BT. He was onboard

about making carb base level and re doing studs.

Coming to now. The engine is supposed to be complete EXCEPT, builder

didn't do any thing to intake. During last week discussion with car shop,

he stated he want to "get measurements with engine in" (makes no sense to

me)

So, to my questions and request for info.

Wouldn't the machine shop instructions be mill carb base parallel with head flanges (then Heli coil studs to be square to machined carb base.

Is there anything I am missing? Would anyone know of a pantera shop/dealer

my builder could talk to confirm the intake NEEDS to have the carb base level. AND can be done without taking measurements in the car.

Or some good replies I could forward him

Yes, milling the carb base flat is just as simple as you outlined. It does not require any in-car measurements.

BUT......

AFAIK, the Blue Thunder “Pantera” intake is the ONLY intake that offers a parallel-to-the-ground design when installed in our Panteras. All the other intakes are designed for passenger cars which install the engine at an angle as opposed to the flat installation in our cars. so those intakes have an angle which positions the carburetor flat when installed in a standard passenger car.

The carb base does not NEED to be milled flat for your Pantera application.

Just about every Pantera on the road does not have a flat carburetor base. The workaround is to fine tune your fuel bowl levels to avoid fuel surging out the vent tubes during hard braking. There is also a modification that can be made to the two fuel bowl vent tubes - connecting the two of them with a fuel-safe piece of tubing that has an air vent hole at the highest point.

milling your intake flat is the ideal approach, but it is likely not worth any more grief in your already frustrating endeavor

Larry

As Larry said, there are many, many cars without this modification and they all work fine. Personally, I don't think its worth the effort.

another update . . .

the desired engine builder acquired a Ford Aluminun dual plane intake he thought was the ultimate for street.

NOW, that another (unkown to me) engine builder had to finish up AND the plan to use Throttle body fuel injection, the consecese is don't use a dual plane !

the take off intake was a Torquer. I dug it out of trash and had local guy skim the base level and increased the threaded depth.

Here is a pic of engine just prior to installing intake. Now the intake doesn't lineup with heads so going to a machine shop for another cut.

Looks good! Nice and clean!

So you’re running a flat tapper cam?

Any other exciting mods?

that is the embarrising question. . . I don't know how the engine is built.

I requested the "G Pence, Street" custom grind.

Hey the good news, its painted and plans are to fit into the bay some time soon

the new shop manager, has promised to send photo's from his phone to me in text. I am NOT phone savy and it has taken me all day to get from text to computer to here. And I don't know if I can repeat

Looks like your boys do really nice work!

The black Trans looks really different ( No - I mean nice different !!)- Is it an epoxy or powder coat ?

the "black" ZF is a Ron McCall recomendation and he did when rebuilding it.

Sale point is it will easily rinse clean.

the silver engine bay (instead of black) was recomended by builder, GunnerZ

Percy,

The coating is originally intended for firearms. It is sprayed on and baked ( much like powdercoat but leaves a much thinner coating that is very durable and chip resistant) at 375deg for 1 hour.

Ron

Joe,

That color looks amazing! The work that has been done looks top notch. Curious why they left the metal tabs in the engine bay instead of routing the AC hoses/wiring harness inside the fender well?

You should be excited! It is progressing nicely.

Ron

My question on the coating is how it handles spotting that could be caused by fuel and other chemicals found in the engine bay???

Larry

If this ZF was coated with Cerakote, it’s pretty tough stuff. Engine builders coat pistons with it! I doubt it will stain or spot from chemicals or fluids. I guess time will tell. I used it on my ZF too but mine was done in a medium gray with Cerakote clear coat over it, to make it easier to wipe up any fluids that will inevitably get spilled on it. Most Cerakote coatings do not require heat to cure, so they work well on porous metals and castings like Campagnolo magnesium wheels. When heat isn’t used to cure, you don’t get the out gassing that’s so common with powder coating. I’ve even had Cerakote applied to plastic, to make it look like metal.

Just a little grinding work and they will be just fine. I had to do the same thing because my car didn't have front bumpers when I bought it and the used set I bought did not fit perfectly.

Well, surely that .4"-ish mismatch is within tolerances lol, j/k. I would have considered the Mr. Fiats at that point, but we all know about hindsight (and for all I know might have been from the same source anyway, there's a lot of that in Panteradom). I truly sympathize. Though being "around the corner" at that point, might not be as noticeable as one would think, but still the principle of the matter.

Nice to see progress continues…. I’m happy for you!

We did this in 4 months but it was just strip and paint. No mechanical! https://www.youtube.com/watch?v=WeGcZWE5ca8

not sure . . . but Yours was my insperation

the sample were labelled Forged Silver (upper) and Phantom Grey (lower)

So you painted using two tones of paint?

did you use the beltline as the dividing line or was it located somewhere else?

if you study the photo of 2511 you may think it is also painted with two tones, but that is just a function of the surface below the belt line catching the sunlight differently than the top.

Larry

belt line and both hoods are the near black. those photos appear to have the silver darker than the sample.

being optimistic here in preperation to getting 5177 back.

what is the opinion of using the VIN in the license plate. I was thinking

THPN5177

(NC allows up to 8 charectors)

You can save a bunch of property taxes by licensing it as an antique. My taxes went from about $100 to $1200 over the course of a year. Of course, you're in a different county. For antiques the assessed value stays at $500 for the life of the car plus you can put on antique plates on it as long as you have a valid registration and carry the valid tag with you. I don't believe you can customize antique tags though.

Looks like some real progress.

Joe

Great to see the progress shots . It is always hard to keep the momentum going after the third year !! Keep at it - the overall end quality will be better than new !

Perc

Looks great! Congrats!

Real progress, looks great! Maybe you will be driving it before the end of this year?

Wow!!! Awesome

@racecarmike posted:Real progress, looks great! Maybe you will be driving it before the end of this year?

that was hoped

BUT, A mix up on the wheels will be a couple months before they come back. (I think they are on a boat to Italy via Panama and the Suez)

speaking of this. . .

Is there 15X7 and 15X8 aftermarket wheels that would work till Campy's come back

MANY years back I got a SS exhaust by Wilkinson (new, second hand).

The shop rebuilding 5177 called to say the driver side is not fitting, interference with gas tank shield and engine mount. (info second hand from Techs through Manager)

My response was it was OK to hammer tubes. I thought I read this has been seen before and forcing tubes would make acceptable.

Is that so OR is there something else?

There was an article in which I believe was in Hot Rod magazine if I remember correctly where they dented some of the primary tubes and it didn’t affect power. They could possibly modify the tubes which would be more work.

Dear JFB,

I have had driver's side header primary interference by the motor mount and gas tank on two sets of GTS headers over the years. On the first set, I discovered years later that the BFH approach was used to obtain suboptimal fitment. With the recent second set, I was smarter and checked with an exhaust expert. His method is to heat the area of interference with an oxyacetylene torch to orange hot and while the steel is relatively soft, then apply a round (various diameters available) to the problem area followed by judicious whacks with a BFH.

The common BFH method applied to cold steel, in my experience, results in a mechanical reduction of ugly appearance. The oxyacetylene BFH and round tool combined with a BFH produces a better esthetic result.

Obviously, not many people will observe such things given the location of the corrections on the primary tubes. Also, my headers were not stainless steel, which may be a important point. It is good to know your options.

Warmest regards, Chuck Engles

I have recently installed two sets of Wilkinson's stainless exhaust and was able to get them into the cars without massaging the header tubes. Instead I used an air file to slightly shave the motor mount and also slightly relocated gas tank shroud. Wilkinson said the he header tube should not touch the shroud and that the smallest of gaps is sufficient.

I did this years ago when Wilkinson first sold these. The answer was as Steve said to shave down the motor mount.

Congratulations!

Must be exciting after a long journey!

Would be grateful of the cam specs if there available, is it a stroker? did i read correctly you made 475 ftlb that's great with that idle.![]()

I've actually "lost" the specs I provided for the grind. I think G Pence changed to specs in post. I do not have any output expectaion values.

The restro shop ia suppose to have keep the paper work from the grinder.

That vid is sopposedly the first crank and no tuning done yet, I am interested in idle and vacuum

bore and stroke are still 351

Ok thanks I see it was Larry's post with some dyno numbers

That’s great news!

Very nice 🙂🙂

Ah, the advantage of an 8 digit custom plate. No one will understand what it means but......

I got up nerve to make the 7 hour RT.

only had a few minutes to look /talk. I did check the clutch effort. while doable, it could slide me accross the dynamat

After being refurbished by ""ferrari shop" the wheel look great, EXCEPT the color is slightly darker.

And today they sent pics with doors and hoods on. I hope the engine screen will clear a factory air cleaner