I've been riding around in Miss P now for the third season and since everything else in the car seems to be working OK now I thought it was time to look into the A/C system.

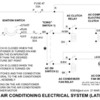

My system is still plumbed with the stock equipment, excepting the compressor which has been upgraded to a rotary type with R12 type connections on the back.

An opportunity to get some R12 refrigerant and oil presented itself. I'd been told that in a stock system R12 worked the best so I grabbed 3 12 oz cans of freon and a matching container of compressor oil.

I borrowed a vacuum pump and a set of R12 gauges from a mechanic friend. I set up the pump and started to draw down the system. Immediately I noticed a sucking noise coming from the receiver/dryer. I found it was coming from a hole in a fitting screwed into the r/d near the sight window. It looked almost like a carb jet.

I removed the fitting with the hole it it and replaced it with a solid set screw plug I found that fit perfectly. Now the system seems to hold a vacuum.

I got to thinking that after a couple of years of exposure to the atmosphere that the r/d was probably nfg. I called the mechanic friend who confirmed that it most likely was indeed junk.

After explaining the fitting with the hole in it to him he said tht it was actually a safety valve that had blown out most likely because of a plugged or otherwise compromised expansion valve.

Replacing the R/D looks like a cinch, and would most likely come with a new safety plug installed. Would anyone have any part #'s or suggestions on a bolt in replacement receiver/dryer?

On to the expansion valve. That doesn't look quite as easy. Whats that like to replace? Dashboard disassembly? My buddy said that R12/R134A compatible expansion valves are available and now would be a good time to put one for when ever I do decide to go to the R134A. Again, would anyone have any advice on part #'s for a compatible valve and the replacement work?

Someday I will go to a front mounted condensor and convert to 134A. But for the meantime I'd just like to replace the these two components and get the system operating.

All commentary appreciated, as always.

Thanks in advance.

Original Post