Ugh, been getting a bit of hesitation & rough running & some backfire on my 427 Fontana Fuel Injected car. I see in 2011 I replaced both fuel filters due to hesitation under load, but I didn't take note of the reading on the fuel pressure gauge reading before (rookie!). Today I had the wife stand in the back by the fumes while I ran it and she sees it is reading about 40 on idle and maintains at 40 with steady increase of the gas pedal which I see from some google searching is pretty much normal. Seems to have started back in Dec so I cleaned the plugs, but the past two runs seems to have started acting up again. I suppose I could pull a plug and take a look at that too and also be sure all is still connected, but is 40 pretty much normal for fuel pressure, or anything else I could look at? I guess I'm trying to talk myself out of a messy fuel filter change if not needed, but if that's all it is I suppose that's not bad from a financial perspective at about $100/filter.

Replies sorted oldest to newest

If you have a steady 40 psi fuel pressure reading, then I would say that you don't have a plugged filter or a fuel pressure issue. Whose ECU are you using to run your injection system? Back firing could indicate an ignition problem. You need to get into the program and check the fuel air ratio settings along with your ignition settings. I am running a FAST XFI 2.05 system that is port injection and in sequential mode and my normal fuel pressure is about 39 psi. I also have a 9.2 deck Fontana block, but am using CHI 3V heads and displacing 388 cubic inches.

39 psi should be fine. Jffr, are you running eight stacks? If so, are you using a remote IAC valve? Are you running the FAST or the Holley dual sync distributor? I'm running the FAST XFI 2.05 with individual throttle bodies without the IAC valve and need to adjust the cold idle rpm tune. I also have a Fontana 9.2'' deck hight displacing 422 c.i. running in bank to bank mode right now, will be switching to sequential mode eventually with the Holly low profile dual sync distributor which I already have. Any input would be appreciated! Thanks

I have the MSD 6AL ignition system. 12 years since I owned the car and its the first time it got a bit funky (besides the time I had to change the two filters and in Dec when I cleaned the plugs). Now I'm thinking maybe it wasn't the plugs needing cleaning but instead something else. Not sure what's up with it, way beyond my scope of abilities if its something up with the ECU/ignition system. Will probably just need to drive it in to my fuel injection engine guy. He programed it when I first got the car. Maybe they occasionally need readjustment? Its not real bad but I notice its not up to par like it usually is. I thought maybe it was a warm up issue, but I ran it a good while and didn't improve.

Jan, is it possible you just got a contaminated batch of fuel? Before you start digging around, maybe degas the thing and refill with some fresh, known-good high octane.

Good thought bossman. I was actually thinking the same, I have one 5 gal can to take out the existing gas but just need to grab another 5 gal can to put in new. I'd like to take out as much as possible and I think I have about 5 in the car now and could run it in the driveway a bit to squeeze out some more or use other containers. I really thought it was the gas filters acting up again, but that 40 psi looks right. I always use the same place for all my cars but who knows bad gas may be a longshot but worth checking anyway.

Well I syphoned out the existing gas from the car (after tasting some) and put in 5 gal of new gas. But in doing so I noticed the gas from the car (Mobile 91 octane) looked quite a bit darker than the new gas (Chevron 91 octane). I only assume a different brand gas could have different color, but who knows I'm no gas man (the wife could debate that!). Anyway in the photo Mobile is on the left and Chevron on the right. Didn't take the car out yet though. If the car still runs odd I may try and rig my gopro near the fuel pressure gauge in the engine bay to see what the PSI is under load.

Attachments

Jan, as gas ages it starts to tarnish like that, it has lost some of the volatiles.

An ECU map shouldn't need updating, what is likely occurring is one of the inputs is reacting differently, a sensor or maybe an injector clogged, especially is the vehicle is sitting for long periods. What are you running for a MAP/MAF sensor?

Yeah it seems something is a bit off. One time it even stalled just after start up and idling. I usually get it out for a good run at least every couple of weeks, but back in January had to let it sit for close to a month. I wonder if I just run it more or just start it up more if it may work itself out on its own such as if gums & varnish happened from sitting. Anyway, will test it out next week with the new Chevron gas in it. I am not sure of the specs on MAP/MAF but looking at build photos it seems it has a Speed Pro ECU (that is if it didn't get changed out from when I bought it.

Attachments

Still a bit rough with the new gas, so I put in some Techron fuel system cleaner anyway and over time see if that has any improvement. Not sure what's up with it. Trying to locate the pressure regulator next. I see some references that say the fuel pressure gauge should maintain pressure when you turn the car off however mine shoots right from 40 to 0. But maybe that's normal for my car with the set up I have. Talked with the fuel injection manufacture and he suspects the throttle body. It seems there's 4 with my car but probably beyond my capabilities to get into that. In the end may need to just drive it to Harv in Whittier.

The fuel pressure drops off after a few minutes or less after you shut your engine off. You really should get you car hooked up to a lap top and see what is going on. Have you tried checking your exhaust header tube temperatures with an infrared temperature gun? That can at least tell you if you are getting good and even combustion on all cylinders.

Thanks for the gun suggestion. Funny I was just thinking of that too, since I am unsure of the real problem. Will need to buy one, any suggestion for heat range? Amazon seems to have several weeks back order on all of theirs, but a parts store here has one that goes up to 840 degrees. I also have a code reader as well that I use on my other cars on occasion, so I may look to see if I can find the input (if there is one). Never saw one under the dash, but could be near the ECU.

Get a thermal gun that goes to 1500 degrees "F". That should be all that you need to check header tube temperatures. I doubt that a modern day automotive code reader will work on your after market ECU. As far as I know all of the after market companies have their own program and you need their software program to get into the ECU.

I tried this for analyzing fuel mixture. Don't be surprised by considerable variation in temp. from these guns. I found the average idle temp on header pipes not far from the heads was around 980F on a Costco temp gun. Shooting the exact same spot on multiple round tubes is difficult, and minute changes in vertical distance away, angle or position can change the indicated temp by 100F or more. You can't tell if its exhaust gas temp variation, or whether its because the spot you checked is not identical on all 8 tubes. Or if its just a cheap gun.

The lower the temp, the less all this seems to affect the gun reading. So its much more accurate on radiator header tanks and useless for checking exhaust mixtures. My 2¢....

Thanks all. I still may get that heat gun, as I probably should have one anyway. Willing to give it a shot just to see if there is any drastic temp differences. I may even take off a stack to take a look at how the throttle body looks inside. If its easy to do, I suppose I could look into each throttle body because the manufacturer said sometimes those valves can bend with a backfire. It looks like I just unscrew these couple of screws on each side and the stack should come off.

Attachments

A 1200 degree max temperature gun will work. You are just looking for major differences in exhaust temperature.

I have been bothered from the first post , but rather reluctant to chime in.

The fuel pressure caught my eye. In a FACTORY EFI system with a fuel pressure regulator and return line to the fuel tank , the pressure varies. At idle and low loads the fuel pressure would be more like 28 psi and as engine load increases the pressure also rises by about 8 to 10 psi. That is done so the pressure across the injector remains constant. (delta is the term) The fuel pressure rises to match the increasing manifold absolute pressure. (decreasing vacuum)

The picture you posted shows a fuel pressure regulator with a small hose on the right side of the regulator. (passenger side) That should be your reference to the manifold pressure. To test it , you would pull the hose off with the engine running and fuel pressure would go up that 8-10 psi. The hose should be dry , any fuel and you have a regulator problem. There should also be some vacuum at the now removed hose.

I have zero experience with a engine with IR manifold and efi. I understand the "vacuum " signal can be erratic. (bounce around) Most manifolds have all cylinders drawing from a common plenum and one large throttle body to meter air flow. Manifold pressure (vacuum) is more stable .

I would look to see the small hose is connected to the manifold and in good condition (not rotten). It is possible the MAP sensor has lost it's connection as well if not bolted to the manifold directly.

I use the Harbor Freight contactless infrared thermometer for $25 . I use it for "looking" for heat in brake rotors and bearings. A industrial quality instrument has a correction factor that has to be entered for the material you are scanning. Copper vs steel vs skin vs what ever.

Another thought is a scan tool does NOT pick up all faults, only sensors that are monitored. It can not tell a clogged air filter or tell a bad plug wire from a fouled plug. They only point you in a direction.

Boss wrench has good advice , start with the logical and simple things and work your way throgh the problem rather than go full "Mike the Snake" mode.

I hope that is food for thought and wish you luck in your repair.

Please keep us posted.

The only eight stack EFI system that I worked on had a vacuum chamber that was being fed by lines that came off of each throttle body. It allowed for a constant and stable vacuum reading. I agree that the photo of the fuel pressure regulator does seem to have a small line on the right side which looks more like a vacuum sensing line than a fuel return line. The aftermarket fuel injection system that I am using in my Pantera is a FAST XFI 2.05 and it has a rather large fuel return line that comes off of the pressure regulator and goes back to the gas tank. The fuel pump pressure stays the same at all times. I have watched it from the ECU on the dash monitor and my in dash fuel pressure gauge. There is also a mechanical fuel pressure gauge that is on my fuel pressure regulator. It sounds like over kill on my system, but I already had an in dash fuel pressure gauge in my car before I switched it over to fuel injection, so I just replaced the gauge with one that worked with the higher fuel pressure that EFI has. Many newer factory EFI systems use a variable pressure fuel pump which does change fuel pressure according to load. I also agree with just starting to look at simple things on this system, but the best approach is to start with getting any fault codes that are coming up in the ECU. That of course means hooking it up to a laptop with the correct software program. This entire problem could still just be a batch of old gas that needs to purged out of the system. The simplest way to do that is just get the car out and drive it like you stole it until it clears itself out!

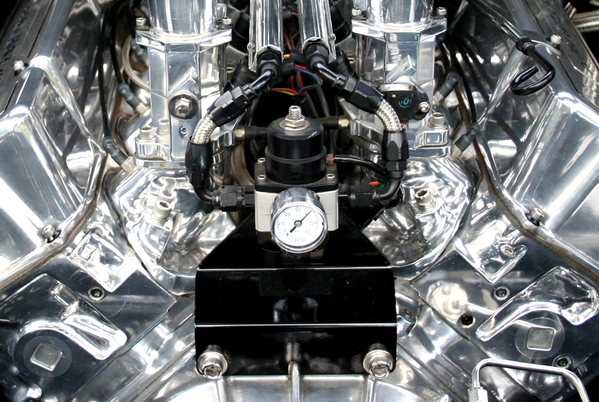

Yeah thanks for putting up with my dumbness. I could just take the car in, but I like to learn as well. If my engine guy was more local I could just drive it in and may do so in the end. Yes I have been trying to find the fuel pressure regulator, so maybe this is it as shown in the photo (the piece top of the gauge?). I did inspect that small tube on the right and that hose is connected at each end. Maybe that's the vacuum hose? I didn't go pulling on it because I thought maybe it was heat wrap secured and didn't initially want go pulling on it. I do have a vacuum test tool, so if that is the vacuum hose I could try pulling it off and testing. I still think its a bit odd though that my PSI drops so fast when turning the car off, because from google searches it seems to indicate that PSI should remain at least for a few minutes. I forgot all about Harbor Freight for tools, so I'm on my way to pick up the heat gun because I figure its good to have one anyway.

Attachments

Jffr you are right, you don't have to vary the fuel pressure. Jeep and Dodge systems put the fuel pump , filter , and pressure regulator in the basket in the tank. There is no reference to the manifold pressure and runs around 39-40 psi all the time.

With a reference line showing in the photo I had assumed it is not a dummy. A 1/8 inch pipe plug or a rubber cap from the auto parts store would blank it off if not in use. They do make regulators without reference as well. They also make regulators that are not 1 to 1 but don't know how or when they are used.

I have seen a equalizing chamber with spider legs to each throttle body used on IR systems. I would expect with out one the engine would be running alpha n fueling. MAP sensors can be directly mounted to a manifold or remotely mounted with a rubber hose. Another thing to check. A rotten or split hose would mess things up here.

I would expect a back fire to be tough on a MAP sensor.

A digital dash on a tablet or phone would be a help here.

I think the Speed Pro system is now part of F.A.S.T.

Looking for bent throttle blades might be jumping the gun.

Jan -

That sure looks like a fuel pressure regulator to me, the black thing.

You are NOT dumb!! Auto mechanics might not be your specality but every day is a oppertunity to learn something new. I have very little hands on experience with EFI but have bought a pesonal library of text books off Amazon. It may be a morbid sense of curiosity.

Trouble shooting auto mechanics is a art. Think it through , start with the simplist or cheapest possible fault and work it forward. Some systems have known weakness and it doesn't hurt to know your enemy. Youtube is not a bad resource , you just have to recognize BS when you hear it.

The injector cleaner and a Italian tune up is not a bad idea. ( drive like it is stolen) I doubt any Pantera owners drive like old ladies , the Pantera has long legs.

Your dash monitor looks great. Had trouble getting the Fuel Pressure Regulator hose off, but it does move around so I know it isn't fixed. But for a quick test I wrapped the connection itself real tight with some electrical tape and tried the car and still bad. Idols around 50 then is still rough when I give it some gas. Then by the time I turn the car off take the key out and run to the back the PSI is 0. I thought there should be at least some PSI remaining with immediate turn off. Tomorrow will try and get that hose off and look at my vacuum tool instructions to see how to test at the FPR and at the hose too. But for my sake in understanding my car can anyone tell me what items 1, 2 and 3 are for? I see the eight hoses labeled 2 go into the manifold but can't see where the eight #1 hoses go. Maybe item 3 screw is for some type of test gauge or just secures it to the car straight through the FPR?

Attachments

Hope you have a fire extingisher in the garage and is handy. Those are vacuum lines and no fuel should be present. # 2, should be 8 of them and they appear to all be going to a common chamber so you should have a solid vacuum signal. That is what jffr refered to in a previous reply.

# 3 is the adjustment for fuel pressure and does NOT need to be adjusted. The hoses appear to be hard plastic and may damage the end trying to get it off the regulator. You are not apt to find hose like that easily. The fitting on the regulator is a barbed adapter. It is slightly tapered on has sharp edges around its diameter to grab the hose. You may not want to take it off and damage any thing. Pretty obvious you have a vacuum signal to the regulator. You could try to ID the brand and part number off the regulator and go read about that regulator and see how it works. With a vacuum line reference I think the pressure should vary with load. There is no other reason to supply a vacuum reference. The specs may say "vacuum/boost rise ratio 1:1" , that means on a boosted engine 1 pound boost raises fuel pressure 1 pound. On vacuum it is around 2 inches HG (mercury) to equal 1 pound less fuel pressure.

The sudden lose of fuel pressure would lead to hard HOT restarts. Without pressure the hot fuel can boil in the fuel rails and when you try to start, the injectors and fuel lines have vapor rather than liquid fuel. At this point we don't know if that is related to the problem or has always done that but no one noticed. Again in theroy it should hold some pressure for hours.

You should try a phone call to the guy that tuned the car and hope he can / will answer a couple of questions.

A fuel pressure regulator is about $150 for a house brand (summit racing) to $350 for aeromotive brand , so determine that really is your problem rather than throw money at it.

I said before no hands on expereince with a system like this but have read about so I am not selling myself as a expert.

#3 in the photo is the fuel pressure regulator adjustment screw and lock down nut. #2 in the photo appears to be vacuum lines that are coming off of the throttle bodies and going to the vacuum supply pod. I don't see the #1 photo, but it looks like there is another line coming from the fuel pressure regulator body that also goes to the vacuum pod. That type of set up looks like what my old factory 1988 Ford Ranger 2.9 V6 engine used on its fuel injection system and it was tied to the fuel return that went back to the gas tank. On that particular system, when the fuel pressure regulator began to fail it caused major flooding problems with the engine. Without actually being there to look at your engine's fuel injection set up, it would be hard to pin point exactly what is going on. It would help if you could find out who built the original system for that car and what tuning mode is being used. From what I understand about those type of IR throttle body systems, they either use Alpha N or Speed Density tuning. I think Lance Nist from southern California built at least one system like that in the late 1980's or early 1990's. I will bet that someone on this forum knows where he is these days, but Lance certainly knows how these systems work and was a pioneer with fuel injection and other cool stuff for Panteras.

Can't tell for sure but there is a 3 wire plug visable on the rear of the "pod" , I would guess the MAP sensor. So would say speed density fueling stratage.

I agree that the plugged in connector would most likely be the MAP sensor.

why not try that go pro camera you have. aim it at the fuel pressure gauge and go for a short test drive. include idle , economy cruise and a very brief high load.

no need to go on the express way or any high speed driving just show a range of loads. I maintain the fuel pressure should "mirror" engine load. low load low fuel pressure , high load higher fuel pressure. did the fuel pressure vary?

If NO , loosen the lock nut on the regulator and back the adjustment screw out until fuel pressure drops to around 28-30 psi. Re tighten the lock nut. now a short test drive keeping speeds and loads low. did drivability inprove? Remember that leaned the fueling so no hot rodding. now restore the fuel pressure setting and decide what to do. careful around the opening in the bellhousing and the rotating flywheel / clutch and don't let the car roll away on you. ( wheel chocks) Not trying to be insulting , just safe.

If you have a oxegen sensor in the exhaust it will try correct the mixture. no action needed just an observation.

Again see if you can get any information on your regulator.

Now you should know enough to talk to your tuner , or some one that knows your system.

I've been interested in EFI conversions for the Cleveland (or Fontana) but I really know very little about the systems. In one of the books written by a company called "TPS" decades ago (1988), they mentioned fine-tuning their GM system by varying the fuel pressure. On a dyno, they ran from 40 psi on the low end to 55 psi and the throttle response & bhp varied considerably. And that was with stock GM-style injectors. Do 8-hole throttle bodies change the rules on varying fuel pressure? 40 psi seems low based on what little I think I know.

That threaded stud (#3) with locknut is how one changes fuel pressure on a regulator. If you remove the 4 small screws, that part of the housing comes off and there should be a rubber diaphragm underneath with a fairly weak coil spring. Possibly the old diaphragm has a small puncture maybe from using CA gas and that's why the thing doesn't hold fuel pressure when switching off.

Thanks for all your help. Sorry, I got caught in all the Huntington Beach protest mess about beach closures but am home now. Yes you are right the car does have an Aeromotive FPR. I am not sure if this one in the link below is the one I have (or may need) but for illustration it does show what the small vacuum connector looks like. So it looks like I should be able to slide the hose off without damage and test at the FPR metal line and/or at the hose/engine line. I have a hand vacuum pump as shown but can't find my instructions or even youtube or google for use on the FPR. But I am thinking if I attach it to the FPR with the engine off and pump the vacuum pump to lets say 10 or 20, then shouldn't the pump hold that same pressure? If it would drop maybe the diaphragm may have gone bad? I like the suggestions to drive the car hard too, but if the FPR is bad I am thinking it may be putting small amounts of gas in the engine which may not be good. Thus trying to test the FPR first.

Attachments

Boss Wrench is right could be a hole in the diaphram. Maybe areomotive might sell just that part as a repair kit.

A hole in the diaphram would explain why you don't hold pressure when the engine stops. It would explain why the fuel pressure does not move from 40 psi. It would explain why the car is not running well.

You are right the hand pump should pull a vacuum and hold when you stop pumping.

If you do get the small hose off you will have fuel present IF the diaphram is ruptured.

You might take a electric heat gun or a hair dryer to heat the plastic line to soften it. to aid in removal. NO FLAMES might encounter raw fuel and that extingisher!!!

If the diaphram is ruptured , it has been adding fuel like a 9th injector.

Might sniff the oil on the dip stick to see if there is raw fuel in the pan. That would be extreme but doesn't cost a dime.

Great idea with the heat gun on that plastic line, maybe it will help it come off. Yes, another excuse for Harbor Freight tomorrow, $10 heat gun on sale. I forgot how great that store is. Main thing is to test that FPR at this point. I had already sniffed the dip stick and there was slight engine smell, but not really gassy smell that I could detect. Already had planned oil & filter, but now waiting till this is solved. When that day comes I will save an oil sample too. Would also like to know how to do a vacuum test at the engine hose. Maybe its the same process or does the engine need to be running?

that heat gun would have no trouble melting the hose so easy does it. I have 2 of those heat guns. softened sheet flooring for removal in the house. I hate sending any more money to China but buy the heat gun else where and it may have rolled off the same assembly line.

here is a link to a youtube video that is decent on fuel pressure regulators.

I am amazed that nobody offers to do what any good mechanic did before gas analyzers and other lambda sensors exist: disassemble and observe the spark plugs after operating at idle and immediately after a full loading, it costs nothing and, even with unleaded gas, indicates a lot about AFR.

first post of the tread Jan took the plugs out and "cleaned "them. He did not observe anything worthy to report.

If its running rich / poorly maybe even smoking looking closely at the FPR is a good place to go based upon my recent experience with the 348. The FPR diaphragm developed a small hole in it. Fuel would push out the diaphragm and into the vacuum line. This caused the engine to progressively run richer and richer. When the problem just began I noticed it just wasn't running quite right. Finally the CEL came on and we began hunting for the problem. By the time we found the problem it was smoking really bad it was so rich. It eventually dumped so much raw fuel into the intake manifold that I had to change the oil / plugs and run the car quite a while before all the un-burnt fuel cleared up. Two months later it began running slightly off again. This time I changed the other FPR on the right side and problem went away. I did dissect / destroy both old FPR's and found both had holes in the diaphragm.

I don't know if that's your problem but this is what happened to my 348.

That's right, back in December I suspected the plugs as a possibility so I cleaned them up even though they didn't look too bad. It did run nice after that but on the next run it started acting up a little. That's when I began hunting around on the web and with you guys for suggestions. I got a heat gun which did help in getting the plastic vacuum line off, then hooked up my vacuum pump to the FPR. Took it up to 20 and it dropped pretty fast (see video). I even tried some other connections to be sure my connections were as tight as possible & thumbed at the end too. Did the plastic hose sniff and it seemed to have some fumes there too. So it seems like that is most likely the issue. Now to find the actual Areomotive unit I need, and as suggested maybe I could just replace the diaphragm from Aeromotive rather than the entire unit. My thought is that I would not prefer to mess with any of the existing fuel line connections, especially if the top just opens and I could replace the bad diaphragm that way. Thanks for all your help with this. I guess in the end the tell tail sign was that pressure drop when turning the car off.

Attachments

Jan, If the FPR is your problem I would just replace it instead of trying to replace the diaphragm. I just went to the Summit Racing web site and looked them up. They range in cost from low $100's to low $200's. Look for the correct fitting size and inlet / outlet ports etc. and replace it. Not a difficult job at all.

I would not worry about whether your handheld vacuum pump maintains vacuum when connected to port on the FPR, too many places you can get leakages that are not related to a problem in the FPR. If the diaphram is ruptured in the FPR, I am pretty sure you will see fuel spitting out of that vacuum port on the FPR when the engine is running.

Also depending on what Aeromotive FPR you have, " NOTE: THE REGULATOR WILL NOT HOLD FUEL PRESSURE ONCE THE FUEL PUMP SHUTS OFF." https://aeromotiveinc.com/wp-c...9/131-0109-0revH.pdf

My Aeromotive FPR does not hold pressure when I shut the pump off. Its not an issue and I see it as a safety feature with no high pressure fuel in the lines / injectors when the engine is not running. ![]()

With the engine running does the fuel pressure change when the hose connected to vacuum port on the FPR is removed?

Is the line connected to the FPR vacuum port rigid plastic?

If that line and the others connected to the throttle are rigid plastic, they could very well be brittle or cracked with age / heat. Check each one and consider having those replaced.

Speed-Pro are now know as FAST. You could contact them to see if you can get the latest software / instructions.

Damn it. Yes item #6 in the link below and also #2. So I probably should hook the vacuum hose up again to the FPR, start the engine and observe the PSI when I take the hose off. If it keeps running at that point then attach a clear hose onto the FPR vacuum port and exit it to the rear of the car just to be safe & see if I get any trickle of gas when running the car for a few minutes.

Finally got back to it. I did three things as shown on the attached paper:

Header temps: With temp gun aimed on the headers I know the temp gun may not be all that accurate because of distance & various things, but I took the temp of all headers before starting and they were all pretty close to equal. Then after a few minutes of running most headers were around in the 500 - 800 range but the one as shown was only 150. So maybe something is up with that cylinder, spark plug or whatever.

FPR: I removed the vac hose from the FPR and the fuel PSI went from about 41 to 48. Also no gas came out of the FPR even after warm up.

Engine Vacuum: Hooked up my mighty vac to the engine vac hose and did a video which showed at idle a bit bouncy vac at around 12, then I gave it a little steady gas pedal which made it bounce around more, then I followed with a small quick rev at the end which made the vac go quickly from 12 to 8 then 18 then 10 and then back to 12. Will try and add the video seperate, only 22MB but it won't load yet. Still can't load the video but basically its as noted above.

Attachments

The injector on cylinder 8 (150 °F) may be leaking.

Remove the plugs and compare the colors, it's at least as accurate as the headers temperature; They must all have the same tint between beige and brown but it is likely that that of cylinder #8 will be either wet or carbon black.

If you are only seeing 150 degrees on the #8 cylinder, then you are either flooding that cylinder with fuel or you don't have any spark there. You could also not be putting any fuel into that cylinder, which could indicate a clogged or defective injector. Either way it would appear that you are only running on seven cylinders. Have you done a compression check on this engine?

Thanks. Yes next step would be to take a look at that cylinder plug after all cools tomorrow. I had them all out a couple months ago to try and fix this erratic running and will check my photos since I numbered all the plug photos. No, never did a compression check on the engine, but all was great till a few months ago. Here is that video I mentioned above. I have a stethoscope listening device so I suppose I could climb in there and listen to that injector and see if it sounds different than a few of the others. I try and just do a little here & there since its in the garage with fumes (door open and fans help a little).

Attachments

Pulled the plug from the engine that showed the low temp header and to me it doesn't look too odd, not like something major. Need to get to the store and put in a new one to test that first but Orileys only has the APP3923 (link below) rather than mine in the photo (3923). A bit different looking on the electrode part although threads seem the same.

Attachments

You have to compare it to the others plugs

Knowing how to "read" a plug requires a lot of experience and I only have a little but it seems very black and greasy, it is certainly not worn but it is not beautiful in any case and shows although this cylinder malfunctions.

A badly functioning cylinder + the fuel pressure which immediately drops to 0, I continue to bet on the leaking injector # 8.

rene4406 look at the link I posted in my reply earlier and does200’s link to Aeromotive faq’s. These regulators are not designed to hold pressure with key off.

The plug (the ceramic insulator) should be a light tan.

That one is wet, and looking very rich.

That does not look right to me.

Rocky

Thanks guys. I found a place with the same spark plug, so I'm on the way to get that and try it out. The plug basically looks the same as all the other plugs that I pulled out & cleaned a couple months ago (although back then they all had a little more black film on them due to not being changed in years). About 10 years ago my fuel injection guy said he tuned the car to be a little rich so I wasn't really surprised with darker plug endings when I checked them all & cleaned a couple months ago. But who knows, I will know for sure when I get a new clean plug in. As far as testing a faulty injector, all I know how to do is to maybe listen with my stethoscope on the injector or maybe also feel the injector to see if the feel or noise is any different than the others, no? Probably will pick up a new plug wire too in case I want to be sure the wire to that plug isn't faulty. Although that will be a pain in the crotch to try and reach back there without going in the other way by the seats.

The app3923 might just be the platinum version of the copper plug you have. The thread and reach is the same according to their website. Take your plug along with you to the store and check the tip to the base of the washer is the same.

It will be ok to run the car for a short while with the one odd plug but you would need to get a new set of what you had originally. They also need to be adjusted / replaced more often than platinum or iridium plugs.

Your plug looks fouled but you need to pull your other plugs to compare.

You could move #8 plug to a different cylinder and see what result you get before buying a plug.

If your new plug fouls / cylinder does not get to temp, then do a compression test or leak down test.

Got the new (same 3932) plug into the engine where the lower temp header is and it still runs rough. Then listened with my stethoscope tool on the fuel injector on the left side of engine and on the right side of engine and did the same listening on the left & right heads. But each side sounded the same. I might pick up one of these spark plug wire testers in the link below just to be sure I have spark through the wire. Probably next step is to find my compression tester and do a check. Its around somewhere because I did my old Maserati Biturbo years ago. I did another quick header temp test and the one was still lower than all the others. I wonder if some of that may just be the header being closer to the engine bay opening & has more circulation to fresh air and therefore may just normally have less temp than the others. Right side did the same with lower temp near the engine bay header although not as noticeable as the left side variance. Next time I pull out my other Panteras I'm going to check the header temps. I still think its too much heat variance though.

Attachments

@bdud posted:rene4406 look at the link I posted in my reply earlier and does200’s link to Aeromotive faq’s. These regulators are not designed to hold pressure with key off.

Ok i hadn't read it all

But this plug does not have a satisfactory appearance and we do not test the injectors by listening to them, even with a stethoscope, we dismantle the rail, we feed the pump and we check that none is leaking and then we make them charge all at the same time in identical and transparent containers and we check if they have all delivered the same quantity.

Check the compression is also a good thing.

Yeah I agree the plug looks kinda dark which I suppose should really be kind of a light tan color but then all the plugs were like that in Dec. If its rich, maybe its not due to excess fuel but instead limited air? The FI company first inclination was the valves in the throttle body could be the culprit. It appears easy enough to take a stack off and see if anything looks odd especially for that one cylinder, although I suppose that could be a longshot. I suppose I could also put my hand on top of each individual stack and see if there is any change in engine sound (spitballin here). As you say the stethoscope didn't prove anything either but at least nothing sounded different from engine side to side on the fuel injector, head or valve cover so at least the fuel injector is clicking. In looking at how to do the compression test on that one cylinder I don't really feel like taking all the plugs out again, finding the fuel fuse, disconnecting the coil. I thought I could just hook up the gauge to that one cylinder and turn it over 3 cranks prior to start and read the gauge.

With an IR intake system, it is necessary to regularly synchronize all the throttles and for that it is not enough to look, you need a device to measure the depressions in each throttle body:

https://www.summitracing.com/parts/bkm-15-2282

the ancients did it "by ear", but you have to have a very good ear and a lot of experience.

Ha ha yeah "ancient" and "no experience" is me. But at least I'm not the average Ferrari owner and would just tow it in. Pantera guys are a bit different. I'm not ruling anything out as the cause, and even on the FPR Areomotive link above it says its normal for the FPR to not hold vacuum when testing at vacuum port with a hand held vacuum pump because its normal for some leakage to occur at the pressure adjustment screw threads. So I may try some silicone adhesive all around the top adjustment screw & test with a hand pump just out of curiosity. But maybe its normally built to lose pressure somewhere else on shut down, who knows, although that would seem odd where its going. Anyway to stinkin hot here in Southern Cal to do anything with it at this point. 90 in CA always feels like 115 not sure why. Going to get a spark plug wire tester and at least make sure my wire is ok tomorrow giving the neighbors a rest today.

Since it is normal that an FPR Aeromotive does not hold the pressure, this is not an indication to take into account and I change my mind, I no longer think of a leaking injector but of a valve synchronization problem in throttle body, as suggested by FI

So I would already adjust the valves before anything else

Coming to the conclusion I'll probably just need to take it in as I think I've tried most everything within my capabilities with you guys helping. Put in my plug wire tester today and that once cylinder is getting spark fine. I did put the palm of my hand on each of the individual stacks too on idle and some sucked my hand down pretty solid and some seems like little to nothing. Of course I'm no engine guy but I would assume they should all suck in somewhat equally. Took the engine to a steady 2,000 after warm up and then a bit of backfire as usual. As you guys are thinking I hope maybe it just needs a tune. So, anyone have experience with fuel injection/engine guys in the Southern CA area (such as Huntington Beach, Newport, Irvine area)? I found these guys on the web as one potential source: http://www.pfaffengines.com/

Well still fartin around with this. I'm finding many engine/tune shops in the Orange County CA area I talked to won't touch the car. But in talking with one dyno tune guy he said he could tune it after he downloaded the program for the Speed-Pro ECU. But he said all that does is alter the fuel/air ratio going to all the cylinders (not individually). I told him that in putting my hand over the stacks on idle that some sucked harder than others, so he feels I should have the individual throttle bodies synched & adjusted first using a syncrometer tool as shown in the photo before doing a Speed-Pro tune. So I went back to looking at the car myself trying to figure how to use such as meter and where any adjustments are for the butterflies. But in looking around I removed two fuel injection stacks just to see what the butterflies look like and just looking at a couple they seem rather dirty as shown. Not sure if this is my rough running issue or not with maybe all of them being a bit dirty. Kind of hard to believe such little dirt would cause rough running, but who knows. I'm not touching it just yet, as I have read some sources say certain fuel injection systems you should not push on the butterflies to clean the butterflies and walls.

Attachments

I cleaned the top surfaces pretty good with a microfiber and brake fluid, but now need to open the throttle and get inside a bit. I would think the edge of the butterfly valves need to be cleaned as most important, but in opening the throttle 1/2 of the valve will flip downward making it harder to clean. Anyone cleaned these before & share techniques? Even a small toothbrush would be hard to get the flipped down portion of the valve when I open the throttle .

Attachments

I was able to open up the throttle to clean the walls under the valves, but in doing so I saw that while pushing the throttle all the throttle body valves on the right side of the engine were not opening as far as the left side of the engine. Makes me wonder if this may be the cause of the rough running issue or not. I'm no engine guy but I would think the right side should be opening pretty much the same as the left. In the photos below show two throttle bodies (#1 is the left rear side and #5 is the right rear).

Attachments

Yeah, need to get them synchronized, assuming it is just across the two banks you can get pretty close with drill bit shanks as a 'feeler' gauge to adjust the right side to match the left.

Hey thanks for the drill bit gauge idea. The company said I need to get both sides set at .002 inch feeler gauge with the valves at rest. Says I need to disconnect the cross link (#3) in the photo then adjust the valves and reset the link to neutral. All left side is already perfect at .002, but of course all the right side is too tight at rest. Plan is to get this bitch adjusted today, getting tired of being in the engine bay with numb legs. Usually I'm just in there 8 hours polishing, but this is something else. I guess one benefit is I'm learning something as I go. Not sure if this is my problem issue, but at least the valves should be adjusted correctly if I don't screw something up worse.

Attachments

Be careful when adjusting that cross-link, Jan. One friend with an 8-stack EFI system would NOT hold a stable idle. It ran perfect when cold but different when hot. After much screwing around, it was discovered that aluminum heads and intakes expand when hot and his hot engine was pulling on the cross link enough to change the idle from 700 to 1400 rpms. I think the fix was simply to readjust when hot and accept however it was when cold.

The hexagonal cross link in your photo looks decidedly bent, it takes a lot of force to bend one, I wonder what happened and whether that isn't the change you see?

Hot damn you're pretty observant. I have had my head above that engine for a couple days looking at how all the parts work and trying different adjustments. But definitely something is off with the mechanisms that are operated by the throttle. I also pondered weather that cross link got bent or was purposely bent initially so that it enables it to pass under the fuel rails without hitting them because it is pretty tight. So I tried turning it sideways and the left side still opens fully and hits the stop long before the right side opens fully. I'm no mechanical engineer so I'm not sure if turning it sideways would make any difference in the "rate" that it opens the left side, but I tried it anyway and no difference. The right side does work and open fully as shown in the second photo but you have to disconnect the cross link. I asked the manufacturer maybe there are different sizes of levers as shown in the third photo, maybe the black lever should be shorter or longer to slow the rate of the left engine side opening so fast.

Attachments

Manufacturer says the linkage is not correct for the left side valves to open quicker and fuller than the right side, but I'm not sure if it came that way years ago from the manufacturer or if someone modified the linkage arm when building the engine. He did say the cross linkage is correct to be slightly bent so it travels under the rails when pressing the throttle. But anyway I have to take things apart and send him the valves & linkage so he can update everything so I need to stick my head in there and see how to disconnect things. But the funny thing is that I adjusted all the valves to his specs at rest (.002 inch) and figured to start the car and see how things run on idle with valves still resting and the engine raced to about 2,500 RPM and backfired, wife crapping the pants in the livingroom. I assume maybe that was due to the Speed-Pro ECU still programed back in the day with dirty valves and now with clean valves and the .002 correct adjustment now things don't match up with the ECU. That is unless something else is still wrong. Finally found my compression gauge in the attic, so I'm going to get to that first. So glad I'm retired to mess with it on and off, but I really would like to drive!

If it were me I'd send the entire manifold fully assembled. There has to be a root cause.

Thanks, I offered that up to send the whole unit back but he just wants the valves and linkages. If I'm thinking correctly, if the throttle arm on the right that pushes the cross link to the valves on the left side of the engine was shorter, that should allow the left side valves to open slower (and hopefully match the right side). As far as the engine revving too high on start up & idle after I adjusted to .002 inch, I may close the gap on the valves a little more and see what happens. I am assuming high rev idle could be from the valves still too open, because that wasn't my problem before cleaning & adjusting things (In fact the idle was like 100 RPM). Im just kind of surprised the engine ran so well all these years with the right side valves not opening as much as the left side.

Ugh, went to check compression by hooking up a remote starter to the starter so that I could turn the car over without the fuel pump going (such as would be the case turning the key on). However that did not work I am thinking because the car has an alarm and maybe that would prevent the car from starting that way unless the key was in the on position. So I am wondering how to disable the fuel pump. Shouldn't there be a fuel pump fuse? I looked in the Pantera manual fuse panel but don't see any fuel pump fuse. I am learning the more these cars are modified, the more difficult they become to work on.

Hi Jan.

The original Pantera’s had a mechanical fuel pump, therefore no fuel pump fuse in the fuse box.

Yours may have a in-line fuse, but you’d have to trace the wires from the fuel pump to wherever it’s powered from.

There may also be Bullet or spade connectors close to the fuel pump. Fuel pumps typically only come with very short leads.

Good luck

Rocky

You can also simply disconnect the electrical connectors of the 8 injectors

Many of the aftermarket EFI systems use a fuel pump relay. You should trace the wires back from the fuel pump to its source. When you find the relay, you can just disconnect it.

Thanks guys, I believe this is the fuel pump. I put my jack away already, so the red wire is easier to get at than the black. Maybe I could just disconnect the red wire & put some electrical tape on the connection or do both wires need to be disconnected to disable the pump? I couldn't find any fuse or other disconnect near by.

Attachments

Disconnecting the red lead will be fine, just be sure to unhook the battery while you are doing it as it's tight and easy to short the wrench to the body of the pump.

Encountered another thing, looks like there are two solenoids on this car, one on the starter and one shown here. Not sure which two leads to connect with my remote starter so I can crank the engine to do compression check. I was connected to the solenoid on the starter itself so maybe that's why it would not start. Look forward to sometime in 2021 to get this back on the road.

Attachments

Connected my remote starter to post 1 and 4 shown in the diagram above and pushed the remote starter button to do compression test but the car still would not turn over. Not sure how else to connect it so I can use my remote starter. I kind of wanted to watch the compression gauge as I turned it over 5 revs, but no luck. So I thought well I will just use the key and turn it over 5 revs then go look at the compression gauge since I already disconnected the fuel pump. But then when I turned the key to the on position I still heard this loud rumble as noted in the video below. I always thought that noise was the fuel pump noise so I was surprised to hear it when I turned the key on. Now I wonder if the fuel pump is really disengaged or if that noise is something else. I would hate to turn the car over with fuel present in doing the compression test.

Attachments

Sure sounds like a fuel pump to me. Do you have a vacuum pump for your brake booster? If so, that's probably what you're hearing.

Yeah maybe the booster, wife said the noise was coming from the front. So I turned it over with the key for 5 or so strokes and the best I got was 90 on the gauge (not good, I understand 120 & above is about norm). Retested a couple times and still 90. That was on the questionable cylinder that had the low header temp reading. So I'm going to put new plugs in anyway all around and check each cylinder while I'm at it.

Jan,

You are better off doing a leak down test (plus it will be easier on your own), you can probably rent or borrow a tester from your local auto parts store, although they aren't overly expensive to purchase. You'll need a compressed air source as well.

Julian

Thanks for the leak down suggestion. I was hoping to not go there due to my lack of experience and short on patience; however it's the right next step. I looked at some youtube and getting to top dead center may be a bit tricky for me, plus it seems I would need to get behind the bulkhead to rotate to get top dead center. I thought my center piece may have been connected separately so I'll see if just that part can be removed. But I did check the next cylinder compression and it was 125. I was kind of hoping to use this compression test guide below as a crude reference, but I can't watch the gauge and crank from the drivers seat at the same time. Or maybe I can rig the gauge to watch from the rear window/firewall while I crank.

Attachments

Jan,

Connect your remote starter switch to terminals 1 and 2. Disconnect the wire at terminal #4. The wire connected to terminal #4 will power your ignition system during cranking.

John

You can find the top dead center by lifting only one of the rear wheels and turning this wheel after engaging the fifth gear.

You know that you have to accelerate thoroughly to measure the compressions?

Hi Jan -

You are getting good advice.

Minor comment... really have to spin the motor rapidly to get a good compression reading (Which really isn’t that hard, with all the plugs removed and the starter motor cranking the engine).

Regarding a leak down test, you have to figure out a good way to lock the engine at top dead center. When you apply the 125 psi to the cylinder, unless you are at exactly TDC, The engine will want to rotate. In our cars you can probably lock it by putting a transmission in gear, and making sure the rear wheels can’t turn.

You will also want to mechanics stethoscope to listen at the intake runners, the crank case, or the exhaust - if you find that your engine leakage is above specification.

you may be taking yourself down a rabbit hole, by trying to fix/test too many things at the same time. Why don’t you wait till your hardware comes back from the shop before you decide that you need to do a leak down test?

They are not as easy to do as it would appear by a quick skim of the Internet, or watching a couple YouTube videos....

But that’s just my $.02

I do applaud you for getting in there and getting your hands dirty.

Rocky

I mean the throttlebodys have to be full open

Thanks everyone. Yes when I get to the point of a leakdown test I may have someone else over to help with that. First just trying to test all the cylinders compression. I did hold down the gas pedal to open the valves to do the compression check, but I found it didn't make any difference in the reading when I kept them shut either. I can rig the compression gauge to see it from the drivers seat, so will just continue to use the key to turn the car over for the remaining cylinders. Battery and strokes are very strong when doing it one by one and after I do a couple cylinders then I charge it over night. So far everything is about 120 except for the first cylinder tested (90). Yeah Rocky I shouldn't have gotten into the stacks/butterflies without doing the compression check first, but I found they were so dirty so I just cleaned them and yes went down that rabbit hole as noted. Didn't send in the valves & linkage yet either. I figure if the engine needs to get pulled I will let a shop arrange all that.

If you want to save the battery and test all the cylinders on the same day, you just have to remove all the plugs before doing the tests.

True it would have been best to remove all the plugs and then test, but I'm half way through now so I figure I should follow the same procedure since I am really looking for any strong variance. In my car anyway its a true pain in the crotch because the plug holes are so deep and I'm trying to be extra careful not to cross thread the aluminum or get the compression socket stuck so I can't reach it. Took me almost two hours to fish the tool out of one cylinder and I'm not tightening either. My compression tool comes with a stiff braded hose making things even more difficult to turn it in tight spaces, but its what I have on hand at the moment. So I put the compression socket in first then thread in the hose. In hindsight for anyone doing this, I would think the more flexible rubber hose would be easier to angle & turn. For the spark plugs I found that using a small piece of rubber hose on the end of the sparkplug at least helps me reach further too.

Well here's the overall results of compression test in green and header temps in orange that I recorded a few weeks ago. Looks like cylinder 1 is most likely the culprit and as mentioned leak down would be best to do next on that. Probably need to now tow it in somewhere anyway since I don't have the capabilities of fixing whatever is wrong regardless of the issue. Problem with non stock engines is no one wants to touch them, but at least I can go in the garage and look at it.

Attachments

@rocky posted:Regarding a leak down test, you have to figure out a good way to lock the engine at top dead center. When you apply the 125 psi to the cylinder, unless you are at exactly TDC, The engine will want to rotate. In our cars you can probably lock it by putting a transmission in gear, and making sure the rear wheels can’t turn.

You will also want to mechanics stethoscope to listen at the intake runners, the crank case, or the exhaust - if you find that your engine leakage is above specification.

Starting to fart around with this again. I found this link on the web below which seems may be pretty accurate in finding TDC other than screwdriver method or other. Would just need a + - gauge. To turn the engine couldn't I just put it in gear and jack up the rear and turn the rear wheels by hand to rotate the engine? I don't prefer jacking just one side of the car because I have the fitted/flush windshield glued in and I have heard jacking one point of the car may have the potential of damaging the windshield or popping out. If I found TDC I suppose I could lower the car and take it out of gear and apply maybe 40 PSI or so from my compressor to cylinder 1 noted above and listen at the various potential leak points by ear or my stethoscope? Thinking 40 PSI to begin with may not rotate the engine but still allow me to listen.

httpshttps://www.youtube.com/watch?v=u2sA-q7_FtQ://www.youtube.com/watch?v=u2sA-q7_FtQ

I am sure you could, but a true leak down test requires a minimum input PSI, and uses a calibrated gauge to give you an answer (some systems read in % leakdown, some just “good”, “marginal”, “bad”).

I guess it’s not clear what you might do with the information you collect.... how do you know if your cylinders are truly bad without measuring the leak down properly? How do you know the status if you don’t check all cylinders and compare them.... although you have some indication based on your compression test.

If you are able to hear leakage, and (best case) it’s only coming from either intake, or exhaust, or both - I guess there is a chance that the problem could be corrected by removing the heads, and performing a valve job.

I am sorry - I didn’t go back and re-read your thread, but on your compression test, have you put oil in the offending cylinder, and repeated the compression test on the low compression cylinder? If compression goes up, that may tell you if you have a ring sealing problem.

Again - I applaud you for getting your hands dirty. I found a home leak down test on one of my cars was very unsatisfying.... I had too many questions about my technique, and it raised more questions than it answered. It was probably because it was the first one I did, and I have no experience to compare my results with.

And in the final analysis - there are only really two (maybe three) answers.... leave it alone, rebuild the engine (or maybe redo the heads alone).

Anyway - good luck. I am trying to be helpful, not discouraging. Give it a shot. Let us know what you find.

Keep all those parts organized!

Jan, just a comment but on your notes it looks like 'front' written at the top of the page, if that is indeed the front of the engine then the uppermost RH cylinder (your current #8) is the #1 cylinder and vice-versa in normal terms. Not critical or personal notes, but if you take it somewhere and talk to #1 cylinder an engine builder will likely assume #1 in the standard orientation.

Thanks for the input. Yes I am still trending toward having someone experienced come over and do the leak down, at least on that one cylinder since it seems that one is showing the most issues. I didn't put any oil in the cylinder and recheck compression because I didn't want to possibly have that alter the leak down test. Yes, that numbering on the sheet was my own numbering to track what I was doing, but when I get it to someone for a fix I will need to make it clearer about the correct cylinders. Its kind of funny because I originally bought these cars partly because they are easier to work on or to find someone competent to work on them, but I am now finding my Lambo is actually easier at least in this instance. With all the hot rods in Southern CA no one in this area wants to touch that engine. Could be I'm just getting old & grouchy. I could just let it sit & rot in my garage and look at it like artwork, but it is really fun to drive when it runs. Plus longtime sitting just creates even more issues. I've been chatting with Tommy about it, so maybe he would be willing to take it on. He has been real good with my cars and is somewhat local.

Tommy was able to take a look at it and we both worked on the engine all day. 64 years old in the engine bay all day sure ain't good for the hips & legs. Leakdown wasn't too bad on that one cylinder, but he decided to pull off the valve covers and found that all the valves were way too tight (no lash). So all were adjusted and then got 175-180 on all cylinders on compression check. I was surprised to see such a dramatic increase, so of course that was real good news. Started the car and sounded real good. Just need to get it out on the street when I recover & see how it goes.

That is great news Jan, glad to hear it was a relatively easy fix and no tear down of motor required. Did you get all the issues with the throttle bodies worked out?

good news for sure

@joules posted:That is great news Jan, glad to hear it was a relatively easy fix and no tear down of motor required. Did you get all the issues with the throttle bodies worked out?

Yeah throttle bodies still need to get sorted out. But they have been like that for the life of the car and it always ran fine, odd but true. I just found that imbalance by accident where the left side opens faster and fuller than the right. Tommy may just fix the fulcrum, who knows. He just wanted to get the car running good for now because he did see a valve stem marred somewhat so he wants to redo both sides in his shop a few months down the road. Im thinking around that time maybe we will address the throttle bodies. Im just glad it fired up so good, sounds like the devil. I would assume the increase in compression may give more power too. This was me on start up:

Attachments

Took the car out and runs excellent. I found it kind of interesting that no literature that I searched indicated that low compression could be the result of tight valves, although many other culprits were mentioned.