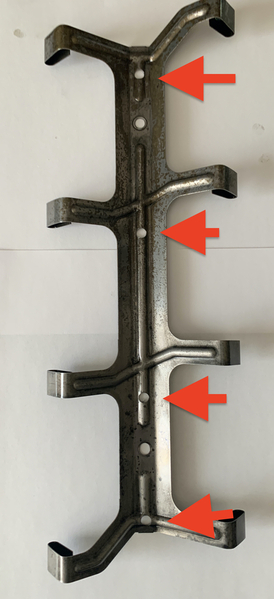

Steve, with your roller cam and the late model dogbone spider to hold the lifter wheels in alignment, did you notice if the spider fits flat to the valley surface of your block? On the retrofit hydraulic roller cams in 351-Cs I've seen, that sort of installation completely or nearly blocks off the Cleveland's rather skimpy valley oil drains. If so, depending on your oil pump it's quite possible to substantially fill the whole valley up with oil. That much extra oil in there might be intruding into areas it shouldn't be able to reach. And of course by the time the intake is pulled, the excess oil has drained back in the pan so there's no evidence.

To fix this on my neighbor's 427 stroker Cleveland, we added three flat washers as stand-offs between the block and the spider for each of the spider bolts. We used longer bolts also. Late model roller blocks have the spider holes threaded in 1/4" high cast stand-off bosses to keep this from happening. There's enough tension in the springy spider to absorb that much stand-off. Cam sellers apparently never mention this possibility in their instructions.

Try it- its cheap, simple and has no negatives if it doesn't fix your smoke problem. Good luck.