10 days into ownership and trying to track down constant radiator cap leaking. Two new caps and still leaking. After shutting the car down I get gurgling noises and the upper heater hose moves around on its own.

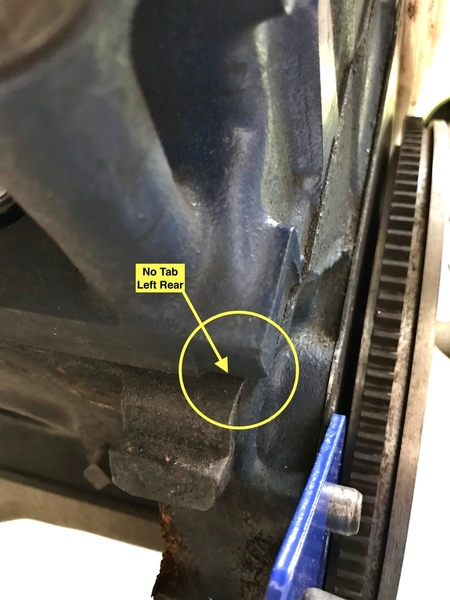

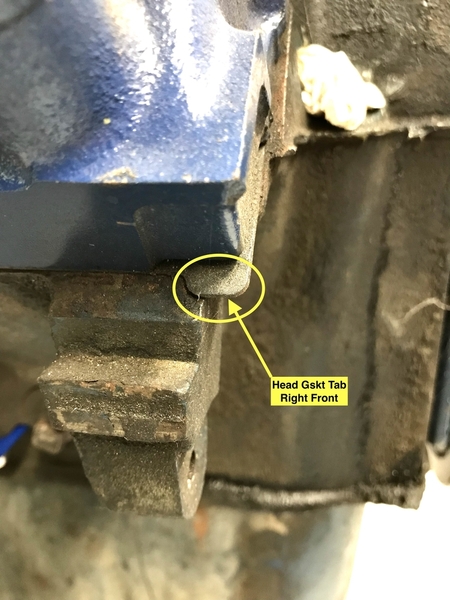

Doing research it sounds like the head gasket might be in backwards. Assuming it is, can you pull the heads with the engine in the car? That doesn't sound like fun but neither does pulling the engine.

The engine was built 900 miles ago by a local old timer engine builder who has had experience with Clevelands.

I can't see a sharp corner on the right side lower but I do on the left side. Back of the engine both gaskets look identical.

Any other troubleshooting steps to confirm?

Thanks.

-John