Take your best guess for the TDC mark, and use a marker or crayon to mark the flywheel. Then check this mark against the balancer mark with the engine at idle and move it if necessary (engine off of course

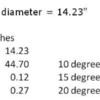

). Once TDC is established, mark the other increments as needed and verify with the timing light.

Once you have established and verified the marks, you can make them permanent (scribing, punching, whatever).

The best way to verify the marks would be to have two people, both with timing lights, preferably with dial back timing lights.

One problem that I see here is that the "pointer" mark that is placed on the bellhousing is too far from the flywheel. This allows an error to occur, as your eye and the timing light must be in the exact location each time, or there will be an error of several degrees in the timing marks. Notice how close the timing pointer is to the harmonic balancer.

As an example, hold up both of your index fingers 6 to 12" directly in front of your face. Align the two fingers so that they are in line with each other (one in front, and the other behind) and appear as one. Without moving your fingers, slowly move just your head to the left or to the right. The finger closest to you represents the "pointer" mark on the bellhousing, and the other finger represents the mark on the flywheel. The fingers appear to be out of alignment when you move your head, but they are not (relative to the starting position of your head). This is called parallax.

This example uses greater distances than are found on the bellhousing to flywheel, but your fingers are much wider than your flywheel timing marks.

John