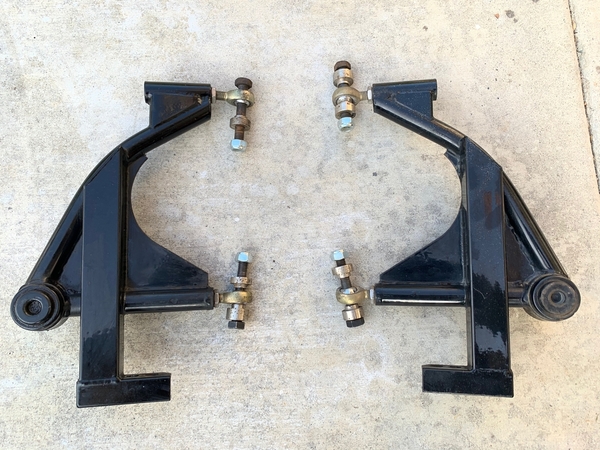

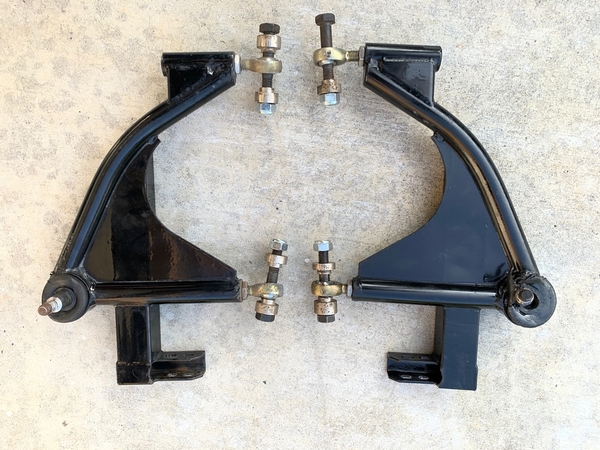

Does anyone here remember the arguments, twenty years ago, between Dennis Quella and Ted Mitchell over rear, upper control arm design? Ted maintained that the correct location for heim joints was on the inboard side. That way, the heim joints were in double shear not single shear and toe was then adjustable as well as camber. Dennis' response was by showing multiple photos of Indy Car upper control arms that were similar to his outboard heim joint design. In Dennis' defense, I'm not aware of a single failure of one of his rear upper control arms.

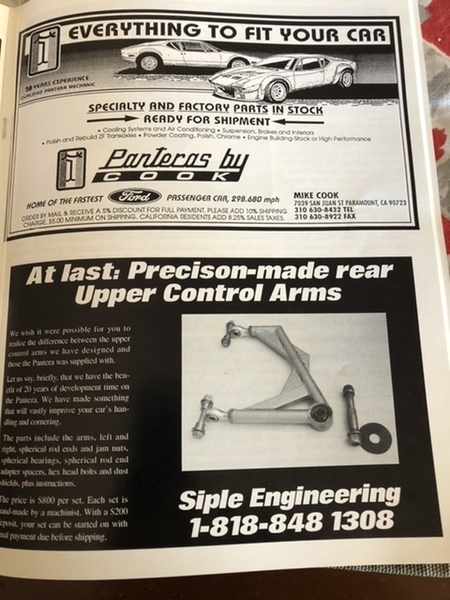

For those people interested in Ron Siple's rear, upper control arms, his e-mail address is: rasiple@aol.com. I have them on my Pantera and I believe George has them too. They're a bit more expensive than others but I can assure you, they're a work of art!