John

quote:PSSS> Garth - good to hear you engine is going back in.. Did you do anything other than fix the bent pushrods/rockers?

quote:Michelin TB5

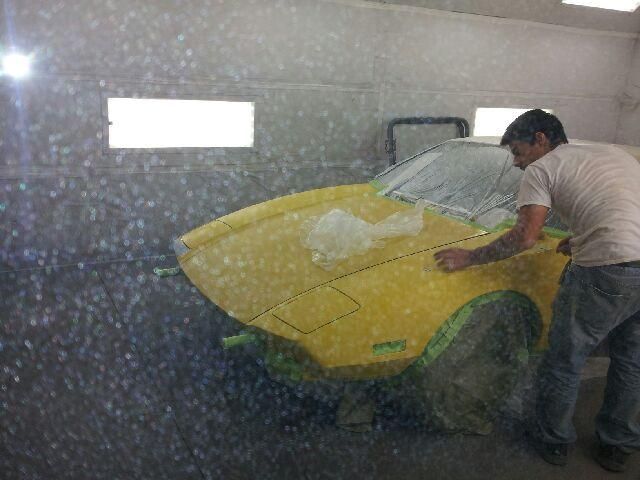

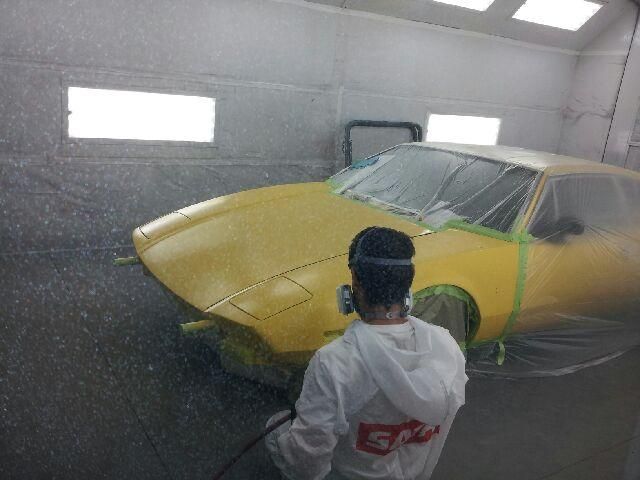

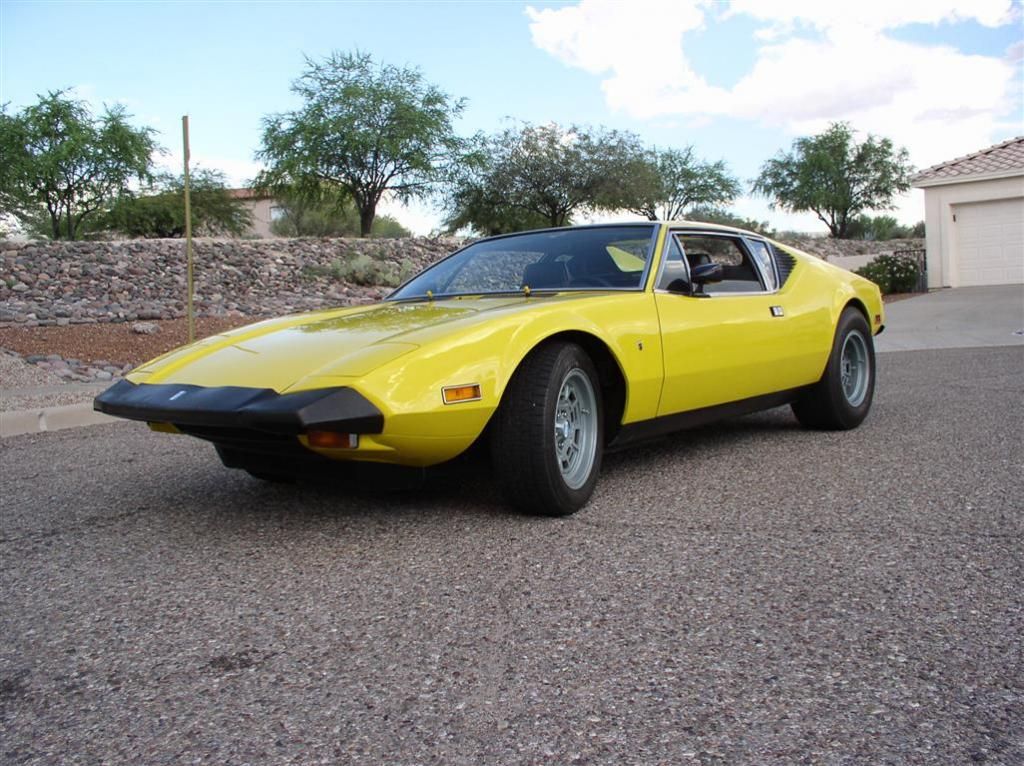

quote:This thread needed better pictures, after all the hard work on the car...

quote:I like the wheel

quote:Originally posted by Mark Charlton:

quote:Nice to hear you are getting sign offs accomplished. How soon do you think for the air tools...those are the fun ones..

quote:The camber lock modification is slick. I like it. Royalties should be paid to you or W-WadeCo?

quote:Originally posted by Rob Borruso:...

Gotta share the details of the very super duper tool in action for us. ;-)

quote:How has the new starter worked?

quote:Originally posted by JFB #05177:

I aint no ex-spert...but a question and comment.

I think your ranges of A/f show and like you say it feels from the other indicates that you have a great tune.

the rich dip at 12 to 15 seconds, would that be a gear selection where you were below your cam and had a slight WOT bog?

quote:rich dip at 12 to 15 seconds, would that be a gear selection where you were below