When I bought my car, the PO had told me about the rear bearing replacement in the uprights, and went to great lengths to describe the custom socket fabricated to do the job.

Prior to disassembly of the suspension I did a "wheel wiggle" test, and found some play in one side of the car.

Upon further investigation, it turned out the play was not in the wheel bearing, but in the bushings in the bottom of the lower upright. Here's a good thread with additional information on the bushing design:

Stubborn Suspension Bushing

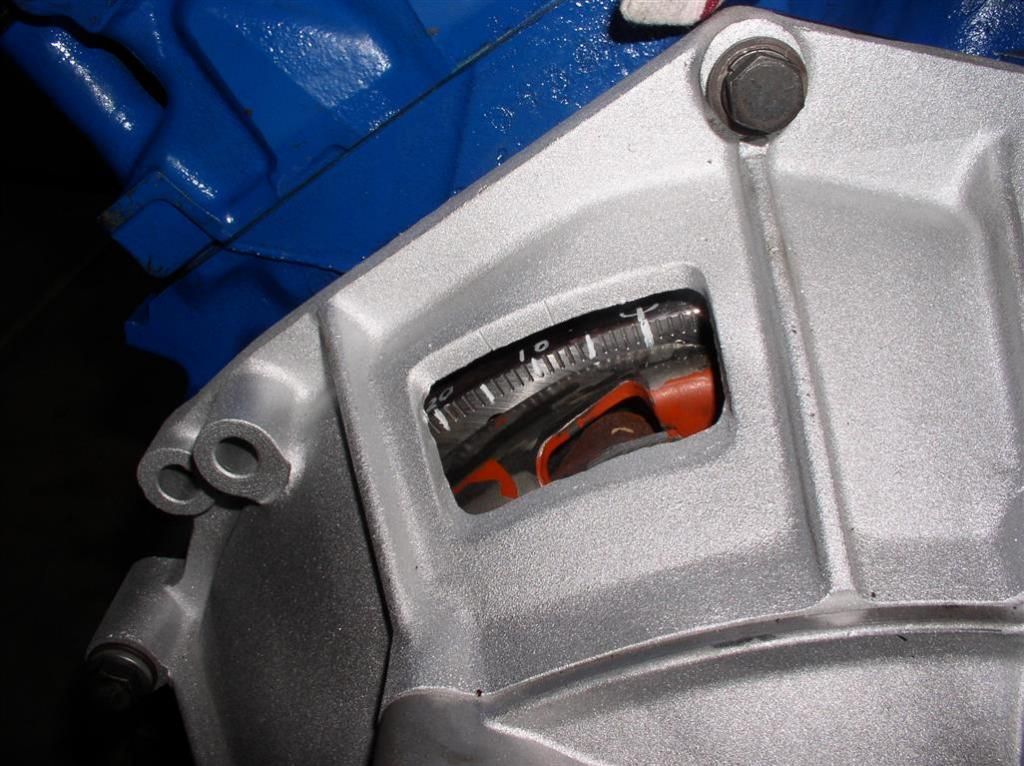

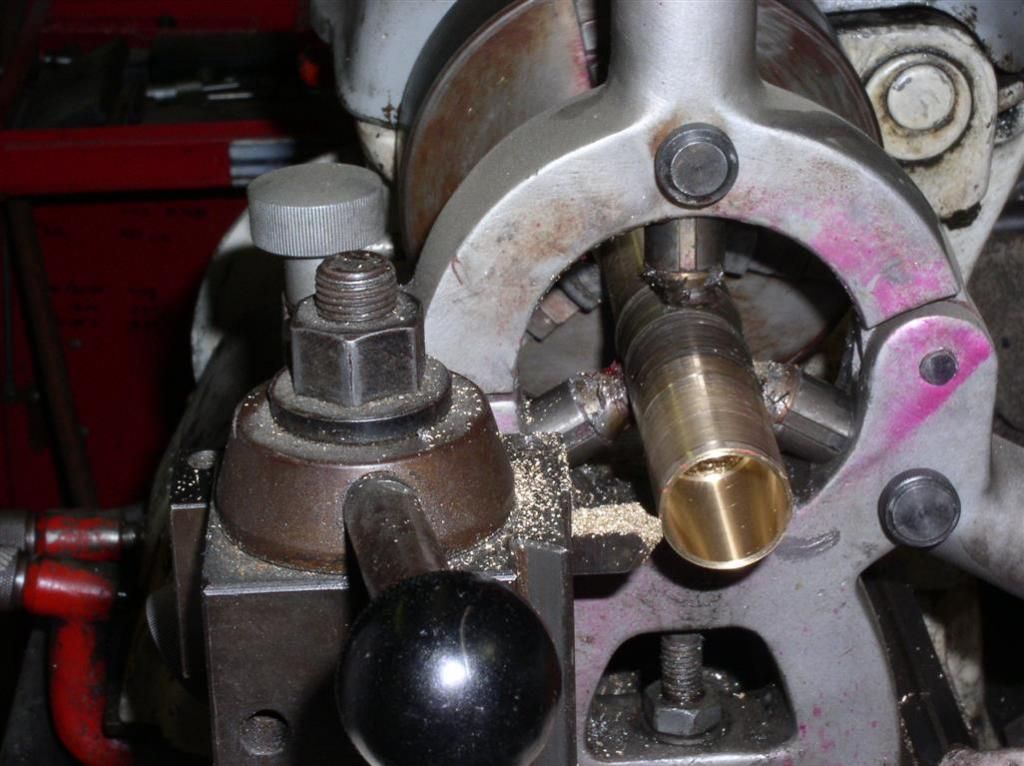

We were in a rush to get the suspension reassembled, so Wade (always up for a challenge) suggested that he fabricate the bronze bushings. The bushings are standard metric size - the id/od/length are mm dimensions 24 x 27 x 29 long.

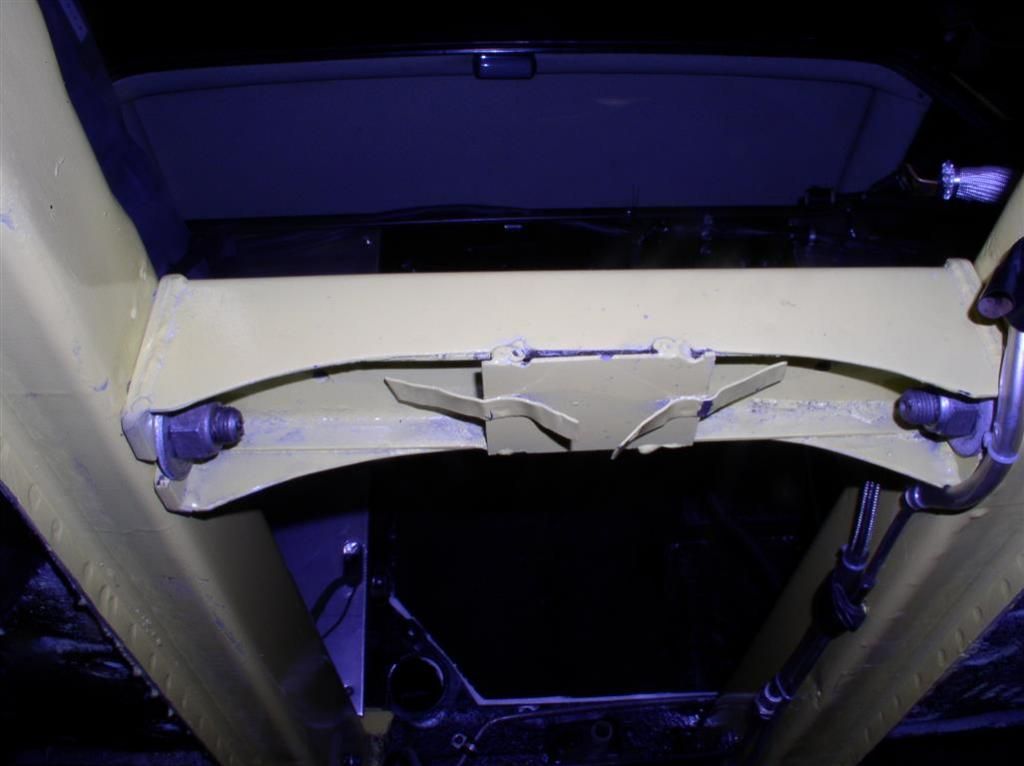

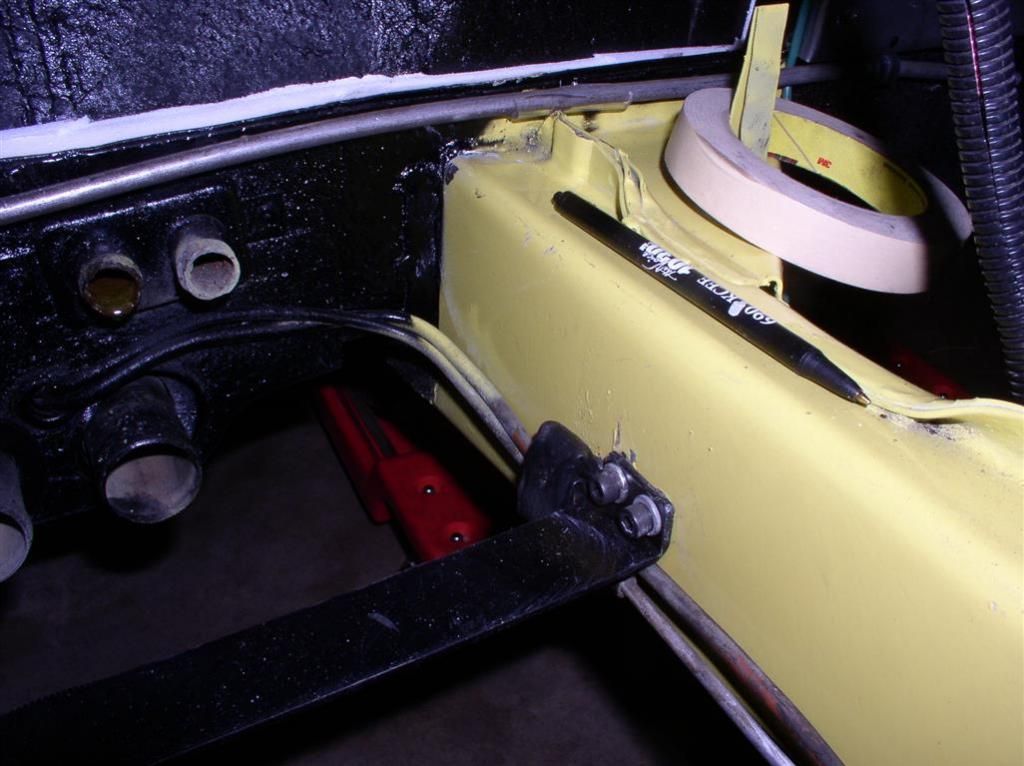

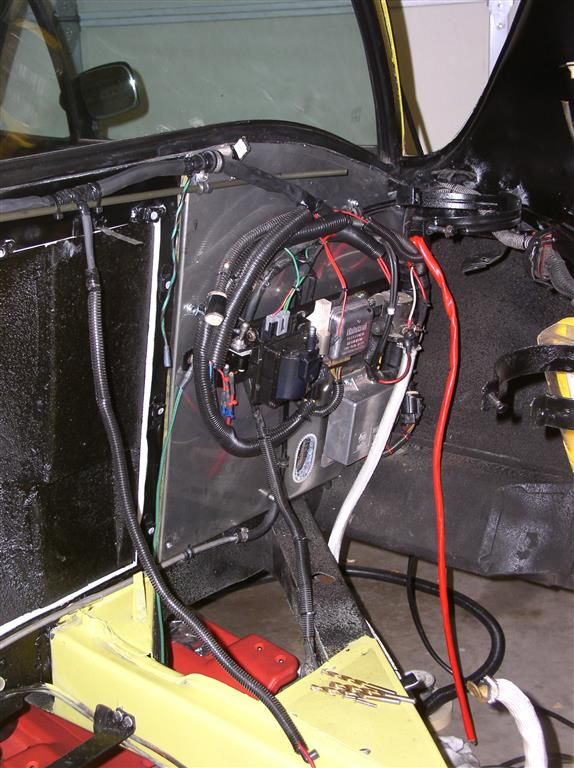

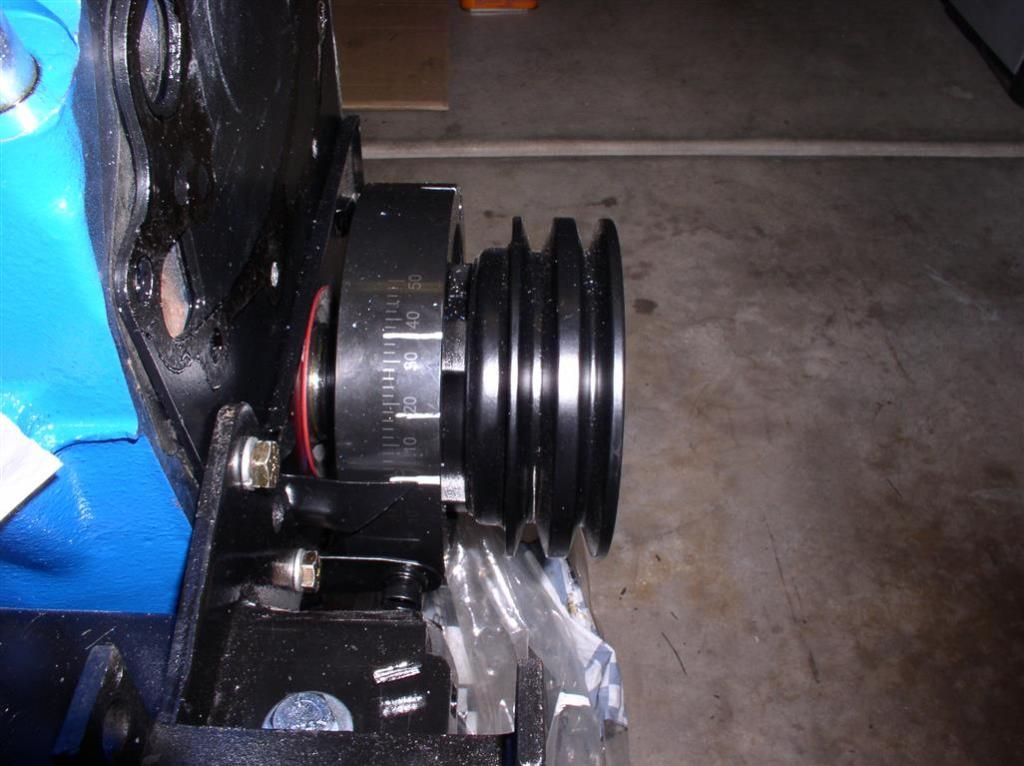

Here's a set of pictures. In the first, you can see (sort of) one of the offending bushings - it had to be cut to removed. The rest is the fabrication and assembly. Lest you be concerned, all bushings were reconstructed and replaced.

I had purchased (on a whim) two upright shafts (from Mayberry Pantera), and a complete bushing / ball joint kit (Maseratisource). All new parts were used in the reassembly.

Another major project successfully completed!

Rocky