Well I know many of you purists are not going to like this.

But I bit the bullet a couple of days ago & chopped off the Pantera’s nose.

I was gutting out the front lights, radiator etc ready for new fenders to be fitted.

When I had removed most of the surplus parts I found the front of the car at some time had taken a bang & has been straightened.

This section of the car does bugger all except support the lights & radiator as well as make the car look pretty.

So it was not the fact that the car was structurally un-sound, just that with crumpled & then hammered straight steel it was a bit messy & did not meet my standard of being acceptable. (someone had covered a great deal of the creases with bog, (bondo) )

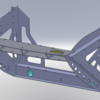

SO……….I took measurements, created a jig that supports the inner fenders from moving during cutting, (the blue structure) as well as another bolt on jig that gives a reference point for the hood hinges.

Then went onto Solidworks & created a new nose structure that supports the bodywork, integrates the hood hinges etc.

This new structure tags together like a jig saw puzzle & laser cut from 2, 3 & 4mm steel plate.

Solidworks tells me I will have a slight weight increase in the region of 4 to 5 kg.

But the alloy radiator has easily saved that amount.

Plus the new nose is a great deal stronger.

Then we cut off the old nose.

This was cut off whilst the car was up on the chassis hoist, not on its wheels which could create chassis flex.

We have added a 65x35x2 RHS crossmember inbetween the the lower chassis rails as well as triangular cut RHS gussets behind this new crossmember.

Also plates to the upper rails that blank them off & give a point to weld the new nose to.

Upon cutting nothing moved at all as 95% of all of the chassis strength is from the front of the suspension arms rear wards.

I was surprised to find no rust at all within any of the structure we opened up.

The old fenders will be completley removed back to the doors & replaced with new items.

Regards,

Tony

Attachments

Original Post