If you had to change your rad now, what would you go with - and why?

1 - OEM

2 - Fluidyne

3 - Hall

4 - other?

Replies sorted oldest to newest

David I'm throwing this in mostly for the new guys reading your thread, but I've made comments regarding radiators that apply to your question. It helps to review why we do the things we do.

Cooling system description

The Pantera's cooling system consists of a short list of components:

The 351C controlled bypass high flow cooling system

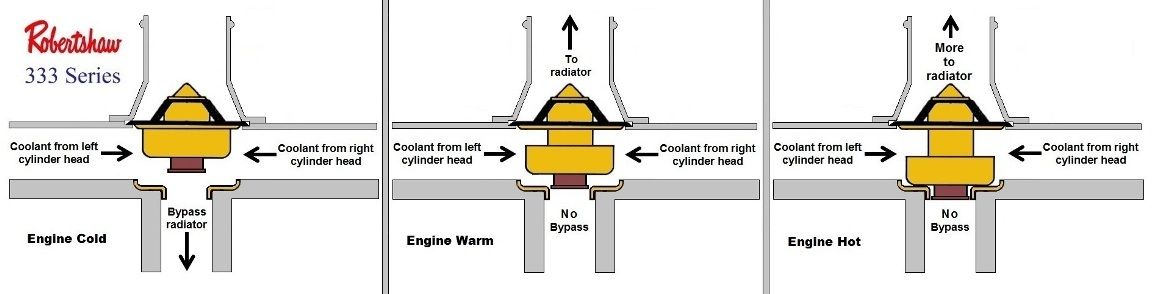

The 351C was designed to employ a Robertshaw high-flow thermostat as standard equipment and it incorporates a unique high-flow warm-up system Ford called a controlled by-pass system. A high volume of coolant was recirculated within the block (bypassing the radiator) during warm-up. This high flow bypass system prevented the formation of hot spots in the cylinder heads while warming the motor to operating temperature more quickly and more evenly.

Diverting a high volume of coolant away from the radiator would lead to over-heating during normal vehicle operation, so coolant recirculation was controlled (shut-off) once the motor reached operating temperature. This was accomplished via a unique 11/16” OD copper “button” on the bottom of the Robertshaw thermostat which extended downward as the thermostat opened and plugged an orifice in a brass plate mounted inside the block immediately below the thermostat. The addition of the 11/16” OD button to the Robertshaw thermostat makes that particular thermostat unique to the Cleveland engine series. The high flow warm-up and controlled bypass aspects of the cooling system built into the 351C were advanced designs for their day, and cannot be improved upon even today but this unique design makes it imperative to locate and use the proper thermostat. The cooling systems of modern motors have similar functionality, but it is accomplished with a "divorced" thermostat, one that is mounted externally from the engine block. The 351C was unique in accomplishing this functionality internally ... and it was accomplished with only a small modification of the standard Robertshaw thermostat. Unfortunately that small modification has been a major stumbling block.

The Pantera's cooling system woes

The cooling system built into the 351C performs admirably if the proper thermostat is installed. Unfortunately the same cannot be said for the remainder of the Pantera's cooling system. Here's a list of the cooling system's many issues:

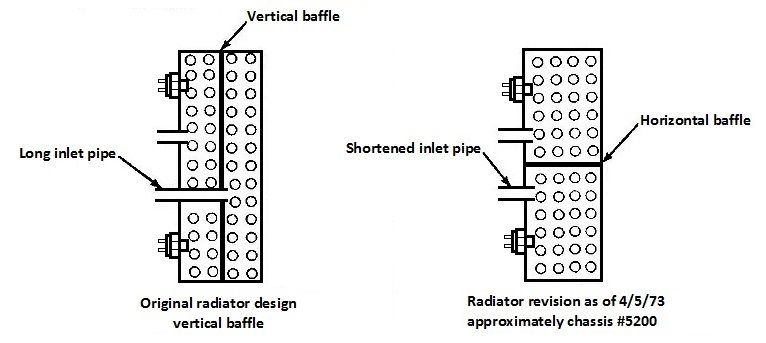

The Pantera is notorious for overheating during stop and go driving. The engine running-on after the key is turned "off" was a secondary problem that annoyed owners. The overheating problem was resolved to a degree by two of the changes mentioned above: (1) revision of the coolant pump inlet plumbing and (2) replacement of the vertical radiator tank baffle with the horizontal baffle. The 1974 L model Panteras could idle all day long without overheating, with the the air conditioning operating, on a summer day ... even with the oem 4 blade radiator fans! Most owners would agree however even the 1974 Pantera's cooling system performance during stop and go driving is perhaps best described as "fragile".

To summarize what ARE the primary causes of overheating:

Subsequent contributors to overheating:

Contemporary causes of overheating

Cooling system specs

Cooling system parts circa 1975

Replacement thermostat

Note: The Robertshaw thermostats have been sold in the past by Stant, Interstate and Prestone using the 333-192 and 333-180 part numbers. The thermostats were also sold by Flow Kooler. The 333-180 thermostat was sold in Australia by Dayco under part number DT66A, and it was sold by Summit Racing under part number BRA-333-180. You should check, but it may not be available from any of those sources any longer. The thermostats have been hoarded by certain businesses specializing in Mustangs, 351C engines, etc. Whenever they become available they are sold out immediately.

Robertshaw 333 series thermostat and the brass plate

that presses into the block below the thermostat

The correct thermostats AND brass plates are available from Marlin Jack.

Marlin is a Pantera owner and a machinist. He manufactured the brass plate

in the picture above. Marlin on eBay

Marlin's email: pantera1974@verizon.net

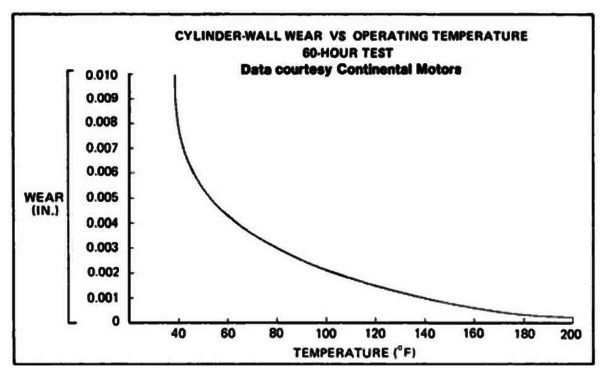

I do not recommend 160 degree thermostats due to the increase in engine wear. see the chart below.

Replacement pressure cap

The pressure cap "neck" of the OEM system tank is designed for European pressure caps, it is taller than a pressure cap neck designed for US pressure caps. Therefore the spring of a US pressure cap is insufficiently compressed and it will not hold the pressure it is rated for. In some cases it will not even seat tightly against the seat. If you cannot find a pressure cap equivalent to the Motorcraft #RS-40 don't despair. You can have a radiator shop replace the European pressure cap neck with a pressure cap neck designed for US pressure caps; or you can purchase an aftermarket tank equipped with the US pressure cap neck out-of-the-box.

Note: The modern replacement for a Motorcraft RS-50A radiator cap is Motorcraft part number RS-62 or Stant part number 10229. The modern replacement for a Motorcraft RL-44 radiator cap is Stant part number 10329.

Refurbishing the OEM Cooling System:

If you follow the steps below your Pantera will have a cooling system that is in May 1973 show-room condition, with one helpful change (elimination of the electric ported vacuum switch) and one helpful addition (a drain cock installed in the top of a radiator tank to make it possible to manually vent the radiator). Don't be concerned about disabling the vent line in order to install the drain cock, because the vent system never worked anyway; this is why it is necessary to manually vent the radiator in the first place. If you do nothing else to the cooling system one mechanical problem shall still exist, i.e. the coolant flow rate shall still be too low. The three electrical problems of the radiator fans are also left unresolved: (1) the fan controls supply the fan motors with power routed through the ignition switch, (2) the fan motors can back feed power to the ignition when the key is turned off, and (3) the fans are always "on" instead of cycling "off" and "on".

Make sure your Pantera's cooling system incorporates these factory revisions:

Helpful changes:

Refurbish:

The Hall Pantera Phoenix radiator makes a practical replacement for the oem radiator for 3 reasons: (1) its less finicky about coolant chemistry because its made of copper, (2) it looks and functions like the oem radiator, and (3) it has an "open" core design that offers low restriction to air flow, making it ideal for use with oem style pusher fans.

The Hall Pantera Mirriah fans were practical replacements for the oem fans. They were equipped with 10 blade Flex-a-Lite fan blades, Hall claimed they moved four times more air than the oem fans. Hall also claimed they drew only 7 amps per motor even though they moved more air than the OEM fans, which draw 8.8 amps per motor. That's 14 amps total compared to the OEM fans which draw 17.6 amps total or the Flex-a-lite model 220 fan assembly which was also equipped with 10 blade fans but was rated at 19.5 amps.

Unfortunately the Mirriah fans are no longer available. Similar fans ARE available from Cool Cat Corp however. And Flex-A-Lite fan blades can be drill-out to fit the larger diameter shafts of the Cool Cat fan motors. https://www.coolcatcorp.com/product/CoolCatFan38.html

Warning The plumbing for the heater core is routed through the center console and up under the dash board. That plumbing includes some rubber hoses. If one of those hoses should burst while you are driving your Pantera it will fill the interior with steam and you won't be able to see where you are going. There is one particular little hose adjacent to the accelerator pedal, if that one should burst it will scald your right foot with 180 degree coolant, you won't be able to keep your foot on the accelerator OR use the brake pedal. This happened to me, which is why I am emphasizing do not neglect to replace the heater hoses within the passenger cabin as you refurbish the cooling system.

Parts Choices

RADIATOR:

I'm not going to be too adamant about radiators. Regardless if you choose to recore your OEM radiator or purchase an aftermarket replacement, all Pantera radiators seem to be capable of performing the job they were designed to do. Here's some radiator info I've learned along the way.

The extra cooling capacity of an aftermarket radiator will be most beneficial for high load driving (high speed, uphill) and driving in very hot climates. Unless your Pantera is equipped with an early radiator having a vertical baffle, or unless the radiator core is fouled by scale, or unless you drive your Pantera in a very hot climate the radiator is not the problem when the engine overheats during stop and go driving. That problem is most likely a combination of the wrong thermostat, air in the system, hose collapse between the radiator outlet and pump inlet, and insufficient coolant flow. For instance, an aftermarket radiator full of air is no more effective at cooling than the OEM radiator full of air. This is not to say the extra cooling capacity of an aftermarket radiator combined with the higher air flow of aftermarket fans may not help a cooling system that is marginal during stop and go driving ... it may ... but it does not address the primary source of the problem.

The choice between copper or aluminum for a radiator should not be a point of argument. Race car builders like aluminum mainly because it is lighter, although there are choices in core design available in aluminum that aren't available in copper. Aluminum radiators can withstand a bit more cooling system pressure than copper radiators because the way in which they are assembled is sturdier than the tin-lead solder used to assemble copper radiators. Today's new car manufacturers have turned to aluminum because it is less expensive than copper. Both metals radiate heat well and both are suitable for use in building radiators. Copper radiators are less prone to being damaged by the condition and chemistry of the coolant, but they are heavier than aluminum radiators and usually more expensive.

The extra cooling capacity of an aftermarket radiator having a thicker core than the OEM radiator will make the cooling system more rugged for high heat load applications, such as driving uphill over a mountain pass on a hot summer day. It is also beneficial for racing or continuous high speed driving. The usual choices in aftermarket radiators include the Phoenix radiator sold by Hall Pantera (copper), the Ron Davis radiator sold by Pantera Performance Center (aluminum) or the Fluidyne #FHP35-PAN radiator sold by everyone else (also aluminum). I must emphasize however the extra cooling capacity of these radiators may not improve cooling problems which occur during stop and go driving.

Left Picture: The Hall Pantera Phoenix radiator;

Middle Picture: The Fluidyne radiator (older FHP30-PAN version);

Right Picture: The Ron Davis radiator

According to Evan's Cooling a radiator the size of the Pantera's radiator with about a 3" to 3-1/2" thick core (i.e. the core thickness of the aftermarket radiators) is good for up to 500 BHP under racing conditions; that should be all the cooling capacity a street operated Pantera shall ever need. As a radiator's core becomes thicker the more it impedes the flow of air. Making the radiator core of a Pantera thicker than 3-1/2" "may" actually hurt the cooling system's performance during stop and go driving by reducing air flow. A custom radiator equipped with a thicker core should pose no problem however for a Pantera race car.

Radiators must be mounted loosely in rubber. There must not be any solid attachment to the chassis, they must be independent of the chassis so any twisting or flexing of the chassis is not transferred into the structure of the radiator.

TANKS AND PIPES:

Stainless steel tanks and a stainless steel coolant pipe kit (1-3/8" OD or 35mm tubes).

If your Pantera needs new tanks or pipes, these should be a life time investment.![]()

This is a 35mm x 38mm silicone hose reducing elbow for connecting the 1-3/8"

coolant tubes to the 1-1/2" radiator nipples of the older FHP30-PAN Fluidyne

radiator. The new FHP35-PAN Fluidyne radiator has 1-3/8" nipples.

FANS:

The small 4 blade oem fans move a reasonable amount of air, if you increase the coolant system's coolant flow rate you may find the oem fans are adequate for your application. This is not to say there isn't room for improvement; higher capacity fans will obviously push (or pull) more air through the radiator during stop and go driving and thus improve the performance of the cooling system when its needed most. There are 4 ways to install replacement fans in a Pantera.

Although fans mounted to the front of the radiator are not as common as fans mounted to the rear, the front mounted fans offer four benefits: (1) oem appearance (2) the radiator can remain up-right (3) no shroud is necessary (4) the fans and the radiator plumbing do not interfere with one another.

Spal is an Italian manufacturer of electric fans that are commonly used and respected throughout the automotive industry (OEM applications, professional racing, motorsports and the aftermarket). Spal fans are available in a wide variety of sizes, configurations and air flow ratings. Flex-a-lite is another reputable manufacturer of electric fans based in the USA.

Always mount the fans in such a way that there is a gap of approximately 1" between the fan blades and the radiator core. Mounting the fans too close to the core will reduce the air moving capacity of the fans. Fans should never be mounted directly to the radiator core. The black plastic ties supplied by fan manufacturers for mounting in that fashion will wear against the tubes in the radiator core and eventually create leaks.

The Hall Pantera Mirriah fans mount in the oem brackets

Mounting one or two high volume fans behind the radiator with a fan shroud will optimize the Pantera's cooling system for street use, the shroud spaces the fans properly away from the radiator core to maximize air flow and it assists the fans in drawing air through the entire surface of the radiator; but a shroud should not be used for a race car or a car driven at sustained high speeds, as it will impede air flow through the radiator at high speeds. The most popular option for mounting fans behind the radiator on a shrowd has been the Flex-a-lite model 220 fan assembly mounted behind the Fluidyne radiator. The Fluidyne radiator has straight nipples (hose connections) instead of angled nipples like the oem radiator making installation of the shrouded fan assembly possible. The two 12 inch fans move air at 2500 cfm (combined) and draw 19.5 amps total. The model 220 fan assembly is no longer available from Flex-a-lite however, it has been replaced by the model 420. As far as I can tell the only difference between the two fan assemblies is the model 420 fans have 8 blades each instead of 10, and current draw has increased to 22 amps total. The air flow rating of the fans is unchanged.

PUMP:

I'm not going to be too adamant about coolant pumps other than to say the pump speed needs to be increased! Here's some coolant pump info I've learned along the way:

A coolant pump that flows more coolant at low engine speed should help alleviate over-heating in stop and go traffic. For the best high-flow at low rpm performance the Flow Kooler pump is the way to go, according to several Pantera owners. Flow Kooler coolant pumps have a unique impeller specifically designed to improve low rpm flow. Their 351C pump is p.n. 1648. Stewart components is another pump manufacturer that is highly recommended. Their stage 1 pump for the 351C, p.n. 16143 is advertised to be "high flow" without any further explanation.

The pump for those seeking the highest flow rate possible is the Stewart Components stage 4 pump. The Stewart Components stage 4 water pump flows 160 GPM! If high flow is what you need, that's the pump. Pantera Parts Connection modifies the Stewart Components 351W pump for Clevelands and sells them ready to bolt on (I believe modification involves removal of the back plate and drilling two holes).

If you're going to use the car in applications where it will be run continuously at high rpm consider the Edelbrock #8844 pump, which is equipped with a cast-curved blade impellar. The forte' of pumps with curved blade impellars is high rpm, they don't cavitate until about 7000 rpm, whereas the pumps with stamped steel impellers are cavitating by 5000 rpm. The pumps with stamped impellers still pump coolant when they cavitate, but they consume about twice as much power. The Edelbrock pump saves about 5 bhp at 6000 rpm. Edelbrock makes no published claims of super high flow rates.

If you're going to use the Weiand #8209 coolant pump, the Milodon #16235 (hi vol) coolant pump, or the Milodon #16335 (std vol) coolant pump I recommend drilling out the recirc passages to at least 5/8"; the passages are plugged as the pumps come out of the box. Drilling out the passages will allow the 351C recirc system to function as designed, it will allow you to use the proper thermostat, and your motor will warm up properly.

The Laws of Physics Governing the Performance and Behavior of Cooling Systems

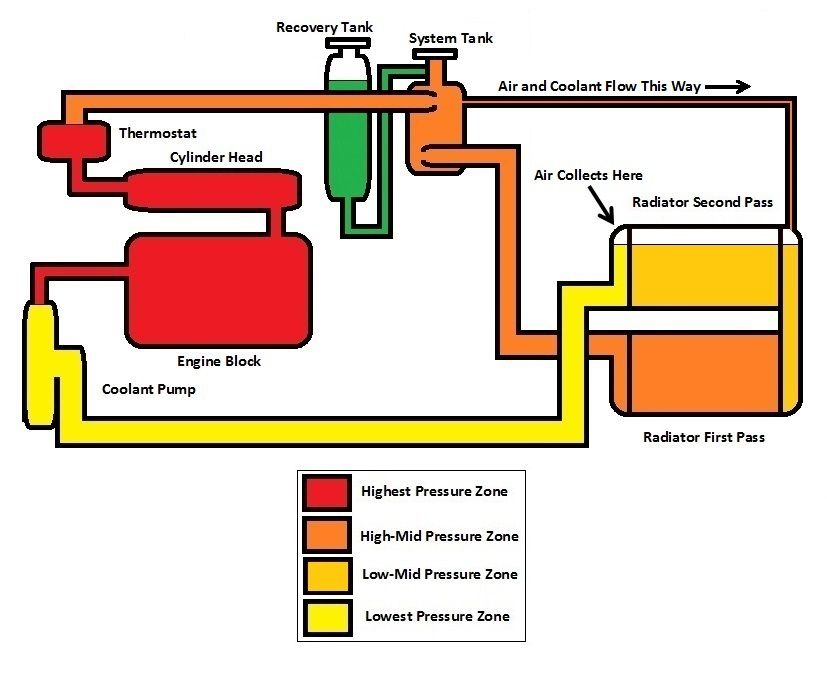

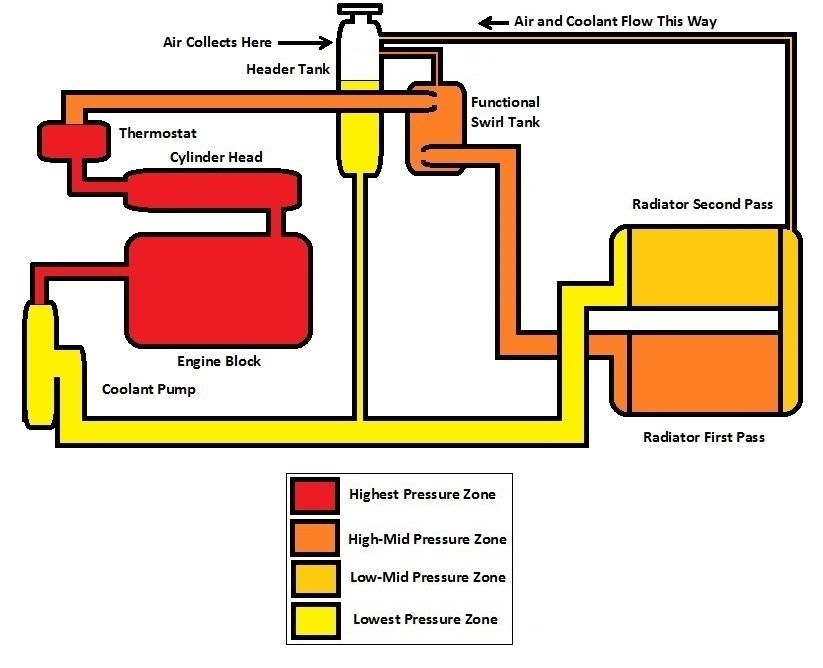

Drawing Detailing the Pressure Zones Within the OEM Cooling System

Observations:

Modifying the OEM Cooling System (fixing the problems):

The modifications I am about to suggest compliment the factory revisions mentioned in the refurbishing section; make sure your Pantera's cooling system incorporates those factory revisions. These additional modifications are aimed at two things: (1) correcting the mechanical problems I identified as primary problems with the goal of making the Pantera's cooling system rugged and dependable with the least amount of modification to the car, especially visible modification; and (2) correcting the electrical issues of the fan controls.

(1) Increasing the COOLANT FLOW RATE improves the cooling systems performance during stop and go driving. There are four methods I shall share with you.

(1A) A simple bolt-on way to increase coolant flow is to install a smaller diameter coolant pump pulley to “overdrive” the pump by 10% to 25%. A high quality 4.9" pulley which over-drives the pump by 10% is available from SACC Restorations. Over-driving the coolant pump by 10% is not excessive, there is nothing to fear. The coolant pumps of 351C equipped Ford and Mercury vehicles were also over-driven by 10% when the vehicles were equipped with air conditioning. Feedback from owners who have installed the pulley has so far reported 5°F and 7°F reductions in coolant temperature at idle.

(1B) The second method to increase coolant flow is to install a coolant pump designed to pump more coolant. Some Pantera owners speak highly of the pump manufactured by Flow Kooler (p.n. 1648) which is designed to improve coolant flow at low rpm. Another option for consideration is the Stewart Components pump (p.n. 16143).

(1C) The third method to increase coolant flow involves increasing the size of the plumbing from the radiator outlet to the coolant pump inlet. There is no kit you can buy to do this, you'll have to fabricate the parts yourself using 1-3/4" OD metal tubing. The radiator's outlet nipple should also be replaced with a corresponding 1-3/4" OD outlet nipple.

(1D) The fourth and final method for increasing coolant flow is to install an electric booster pump at the radiator outlet. Stewart Components sells two such pumps for this application, model E558A and model E389A. These pumps are compact and lightweight. They are designed in such a way that if they fail they will not block the flow of coolant in the cooling system; this is a very important feature. Both are rated for 10,000+ hours of operation. I know several owners who have installed booster pumps, and all are happy with the results.

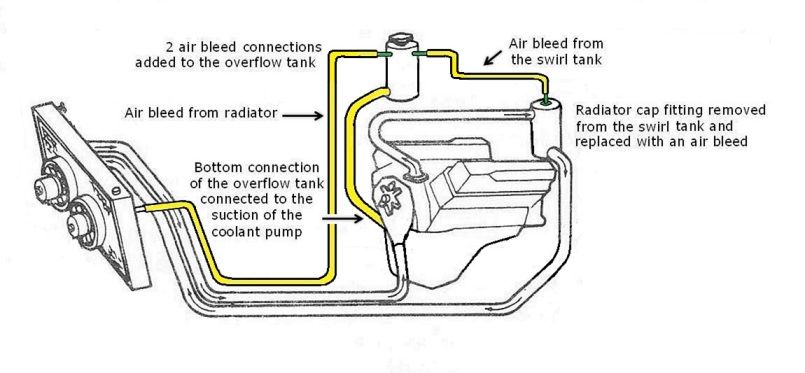

(2) If you would like the VENTING SYSYEM in your Pantera to function automatically (so you don't have to vent it manually) convert the expansion tank to a header tank and plumb the system vents to the header tank. Very little modification is required to make the vent system functional, the tanks appear to have been originally intended for this purpose. The revised plumbing mimics the standard vent system installed in racing cars, and in modern passenger cars too. Feedback from owners who have performed this vent system modification has ALL been positive. Here's a diagram displaying what to do:

If the tanks are not modified to make the vent system functional, a drain-cock should be installed in the top of one of the radiator's tanks where the fitting for the vent would normally be installed, thus making it possible to periodically vent air from the top of the radiator manually.

Behavior of the Re-Designed System

(3) A WIRING REVISION for the fans and their controls, should accomplish 3 things:

It appears the Pantera's radiator fans have always run continuously in the factory installation and in the typical aftermarket installation as well. There is no purpose for this however. If radiator fans run constantly this indicates the coolant never becomes cool enough to reset the fan switches. This could be caused by a cooling system with mechanical issues causing the thermostat to operate wide-open, or this could be caused by fan switches with reset settings which are too low for the thermostat. Assuming the cooling system has no mechanical issues which cause the thermostat to operate wide-open, the fans should turn-off completely when the vehicle cruises non-stop at typical cruising speeds. If the reset settings of the fan switches are too low to allow this then fan switches with higher settings are obviously needed to cycle the fans.

My solution to resolve the issue of the Pantera's constantly running fans is to control both fans with one fan switch so the fans will turn off and on simultaneously; the fan switch shall have a very specific temperature setting allowing it to start and stop the fans in the middle of the operating range of the thermostat. The mid-point of the fan switch operating range should therefore compliment the mid-point of the thermostat's operating range as closely as possible. The fan switch should be located in the radiator's inlet tank (the lower tank) so as to sense the coolant temperature regulated by the thermostat. This solution, as well as solutions for the other two fan circuit problems are reflected in the wiring diagram below.

The mid-point in the operating range of a 192°F (89°C) thermostat is 94°C (fan switches are rated in degrees C). Therefore a fan switch rated at 97°/92° shall best compliment a 192°F thermostat.

The mid-point in the operating range of a 180°F (82°C) thermostat is 87°C. Therefore a fan switch rated at 90°/85° shall best compliment a 180°F thermostat. I have been unable to source a fan switch with M22 threads rated at 90°/85° however, switches with a rating of 92°/87° are the closest I've found.

These considerations are reflected in the switches I've recommended below. Here's the part numbers for name brand fan switches with M22 threads:

Manufacturer...Part Number.........Switch Setting........Thermostat

Intermotor......50190..................100°/95° ..............195°F (91°C)

Intermotor......50104..................97°/92° ................192°F (89°C)

Intermotor......50200..................92°/87° ................180°F (82°C)

Wahler...........823.959.481.F ......92°/87° ................180°F (82°C)

Maintenance:

If you do not perform the vent system modification explained earlier, then you shall need to manually vent air from the top of the radiator as a regular step in maintaining your Pantera. To make this possible a drain-cock should be installed in the top of the raidator's tank where the fitting for the vent would normally be installed.

Fill the cooling system with a 50/50 mix of green Anti-Freeze and water that has had the calcium and magnesium removed. Calcium and magnesium are the minerals that make water "hard" and create mineral deposits and scale. You don't want mineral deposits or scale in your cooling system. If your tap water is naturally low in mineral content you are lucky, go ahead and use your tap water. If not, you'll find several types of water on the market; softened water, carbon filtered water, reverse osmosis water, distilled water, deionized water, double distilled water, high purity water and ultrapure water. Unfortunately the information regarding what type of water to use in a radiator is confusing and contradictory. The ionic state of water is manipulated by any water treatment process; water with an imbalance or depletion of ions can possibly corrode or pit the metal in your cooling system, resulting in pinhole leaks in the radiator core or heater core, so you want to avoid using water with an imbalance or depletion of ions. The chemicals in anti-freeze and coolant treatments are formulated to control some of these problems, but those chemicals are depleted with age and use, so I believe it is wise to fill the system with the best water possible to begin with, the best water being water that will not leave deposits or scale in the cooling system and will not corrode or pit the metal in the cooling system either. Norosion claims softened water is the safest to use, as the calcium and magnesium are removed via an ion exchange process, so the water is not left in an ion depleted condition as it is with other processes. For this reason I place softened water at the top of my list. Reverse osmosis water and distilled water (single distilled) would be the second best choices. Reverse osmosis water and distilled water are normally fed into a deionizing resin bed to produce water labeled deionized, demineralized or high purity. Double distillation is another process used to produce high purity (aka ultrapure) water. Until I learn otherwise I have decided to avoid water labeled deionized, demineralized, double distilled, high purity or ultrapure.

Ron Davis recommends using pre-mixed coolant, i.e. the coolant you buy by the gallon that is already mixed with water. That way which type of water to use (and other chemistry issues) become non-issues.

Other cooling system details include making sure the engine to chassis grounds are clean and tight, and using a coolant treatment like RMI-25, Red Line Water Wetter or Norosion HyperKuhl Super Coolant (blue). The coolant will become corrosive with age and use, this is why the cooling system should be drained and refilled with new coolant every 18 to 24 months unless your coolant treatment specifies otherwise. For instance, Norosion claims if you add their treatment every 12 months you can extend the coolant service interval to 5 years.

The speed of a DC motor is dependent upon the voltage applied to the motor, if full voltage is not applied to the cooling fans they will not run at full speed or move air at their rated capacity. It is imperative to keep the wiring connections to the cooling fans clean and tight to prevent voltage drops across high resistance connections.

Reading: If you want to read more about the design of cooling systems like the Pantera's, refer to Carroll Smith's three books: Prepare to Win (page 122), Engineer to Win (page 170) and Tune to Win (page 97).

-G

quote:OEM rad lasted 24 years. I never had cooling problems so when it sprung a leak I had it repaired for $50.

But instead of putting it back installed a Fluidyne. Can't say it cooled any better but it looked cooler. Anyhow, less than 3 years later it's leaking from 3 or 4 spots. It costs more to repair than buy another one.

quote:Originally posted by garth66:quote:OEM rad lasted 24 years. I never had cooling problems so when it sprung a leak I had it repaired for $50.

But instead of putting it back installed a Fluidyne. Can't say it cooled any better but it looked cooler. Anyhow, less than 3 years later it's leaking from 3 or 4 spots. It costs more to repair than buy another one.

And THAT'S why I went with an OEM style copper/brass radiator. They're proven effective, and can be fixed in short order by any radiator shop or full 'service' gas station anywhere in the country.

quote:Someone had mentioned recently about having the original recored and putting the 'body' of the orginal radiator around it to look and fit like OEM.

Garth, is this what you mean by OEM style?

quote:I noticed in your picture that the top radiator hose is on the driver’s side of the car where both of mine are on the passenger side.

quote:Originally posted by DOES 200:

Here is a shot of the Ron Davis radiator in my Group 4 car. Not a good shot, but too lazy to get the car out of the stacker right now to get a good photo. Dude I got the car from said he had it custom made with Ron, but who knows if that is right or not. It is thicker than the Fluidline I have in my red 5S and has a hose at the top too. Will take photos & measure thickness later when I am sober.

quote:Originally posted by David B:

Okay, let's hear some experienced voices.

If you had to change your rad now, what would you go with - and why?

1 - OEM

2 - Fluidyne

3 - Hall

4 - other?

quote:Originally posted by 1973 Pantera:

I'm still running the stock radiator; it's never been removed from the car since it was installed at the factory 40 years ago. Try that with an aluminum one. My system is stock except for a better dual pusher fan set up. Never any overheating problems at all.

I'm meticulous about changing all fluids every year. My Brake Master Cylinder, Clutch Master Cylinder and Clutch Slave Cylinder all made it 39 years. I'm still running the original 40 year old Brake Calipers and Water Pump.

Change your fluids annually!!

quote:Originally posted by IndyDave:

... They were blown away by the quality. Said it was worth every penny ...

quote:What type of fan did you upgrade to? I'm considering rebuilding my OEM rad that I just pulled out of my 1974 Pantera. I've heard too many stories about the Fluidyne leaking after only a few years...anxious to hear about yours...

John in Fort Erie Canada

quote:Is there a way to recognise from a picture a pre-74 radiator with vertical baffle from a later design with newer horizontal divider?

-Sami

quote:Originally posted by Bosswrench:quote:Is there a way to recognise from a picture a pre-74 radiator with vertical baffle from a later design with newer horizontal divider?

-Sami

No, but sticking a piece of wire in the right side bleeder valve will tell you. If the wire goes in all the way to the back of the tank, the rad has a horizontal baffle. If the wire only goes in about halfway, it has the earlier vertical baffle and should be changed. DeTomaso TSB Bulletin 2, article 35 shows the factory modification.

Corvettes, Z-28 Camaros and many other road cars have had stock aluminum radiators from the factory since the late '60s. The technology is 'mature'. Alloy rads remove a huge amount of front end weight: a stock '72 Pantera brass radiator weighs 64 lbs. A custom-built brass replacement weighed 45 lbs and a Fluidyne aluminum rad weighs 16 lbs. The Fluidyne cooled our engine much better than either of the brass ones (15F lower on long fast highway runs with no other changes).

The water you dump in the radiator will determine the assembly's life. Some areas have such corrosive water that an unprotected alloy rad has an operating life of a year or less. Most vendors now supply a bottle of 'No-Rosion' anti-corrosion fluid with all their aluminum radiators and there are others. They also suggest changing all the coolant yearly. Corvette shops stock anti-corrosion sacrificial anodes (Mag or zinc)to be put in the coolant tanks. The anodes dissolve rather than the radiator, cylinder heads or block.

Finally, home-handymen(?) tend to wind bleeder valves and other threaded parts into aluminum alloy with far too much teflon tape and force: I've seen NEW aluminum radiators with pipe-threaded aluminum bosses split wide open, returned under warranty as 'defective'. Cooling systems seldom see 20 psi; we are NOT sealing high pressures or explosive fuel here!

quote:Originally posted by Yakone:

Years ago, I had a long conversation with Gary Hall. We discussed different cooling setups. The aluminum radiators while lighter but that advantage isn't worth much, the front of the Pantera is too light anyway, taking weight out of the front isn't a big help. He also recommended the use of a 160 degree thermostat. The 160 degree thermostat is what the '71 Pantera's had from the factory, the use of the 180 degree thermostat was used because of the smog requirements in later models. I have used the 160 degree thermostats, but finding them is very difficult.

My pantera is modified to 435hp, while the stock setup worked for the original it failed at the added horse power. I tried several setups with little improvements. Then I converted the AC condenser core into an aux cooler by rerouting the water from the heater core. This dropped the temperature 5-10 degrees. For the most part, the car runs at 160-165, going up hills it will reach 185 degrees. (That is when the first set of fans come on.)

quote:I run a 160 also with the stock radiator. Runs fine. Never goes above about 210-220.

quote:Originally posted by Italian hot rod:

[QUOTE]

Just like the Wizard of OZ said - "Pay no attention to (that temp gauge in the console".) It will just make you nervous.

quote:

Originally posted by HayDude:

... Is the connection to the suction of the water pump the same one the goes to the heater core ...

quote:

Originally posted by JFB #05177:

... your illustration shows the vent on the far common tank, thus there will be a slighly higher pressure here than if it was on the exit tank. Is that intentional? ...

quote:

Originally posted by JFB #05177:

... Is there an adaptor to use the more common threaded switches ...

quote:

Originally posted by JFB #05177:

... I was thinking if the switch was located in the outlet tank, it could determine if there was air flow causing the exiting fluid to be cooler than the thermostat regulated radiator inlet temp and thus start and stop the fan based upon car speed. it appears the original design's intent was to do this (with a 10c and 20c drop for a 192F thermostat), but the horizonal tank baffle modification defeated that for one of the switches. Is there experance to indicate this does not work? ...

Ok, there is a ton of great info in this Topic and I appreciate all who have contributed. Here's where I am on this issue:

1. I want to go with a brass/copper radiator like the Hall.

2. My car has older Flex-a-lite sucker style fans installed now.

3. The radiator from Hall only has about 1/4-3/8th" clearance between the back of the radiator and the bends in the inlet/outlet tubes which is not enough to fit the sucker fans/shroud within.

So what have others done? Do I have to have the inlet/outlet tubes extended? Do I have to forget sucker fans and only use pusher style fans? Do I use the Brassworks total system? Does anyone else here have this Brassworks radiator/fan system installed? It's a bit expensive compared to buying a Hall and even new Flex-a-lite fans but appears to be a quality unit. Steve Wilkinson indicated that the Hall was so much thicker that it would need to be laid down at an angle rather than in the exact same place as the original - I'd rather not if possible.

Trying to follow all the expert advice and great information here from George and others I have ordered the Flowkooler 1648 water pump, the SACC water pump pulley and a new Holley/QuickFuel HR-735-VS carb with annular booster venturis to help. I have already installed the Hall SS pipes underneath, SS bottles in the rear and Gates green line hoses and belts everywhere. I've also added the cut-off valves to the cabin heater. I have installed the correct Robert Shaw 330-180 thermostat (with the hat) and have the brass plate installed, but I'm still getting gurgling and almost regurgitation after even only short drives so I want to complete the replacement of the entire cooling system. I realize there are still more areas to cover, but I wanted to start with what I have done plus the new items mentioned above. I also realize that a very thorough burping of the system after the installation of these parts is a requirement.

Steve W. also suggested that I not install Scott Bell's billet water pump pulley because it would help circulate the coolant too fast through the radiator and not allow the radiator to get the chance to cool the coolant. Sounds reasonable, but others here recommended the pulley so I bought it and it showed up yesterday - thanks Scott for the quick turn around!!

So please weigh in, flame if you must, and tell me what you think.

Merry Christmas and Happy Holidays to all!!!!

If you are going brass, I have the Hall Phoenix big boy in my black car although it had to be laid foreword. Works great. I used to own an orange stock L and it had one in there too & worked real nice till it sprung a leak after many years. I recall my wife assisting to get it out of the car and the thing was pretty heavy (that's what she said lifting it out).

https://www.flickr.com/photos/102810426@N07/12241128314/in/album-72157635769607434/

Does200, thx! Steve W. has a kit to lay forward the Hall radiator without having to weld any new tabs or anything - is that what you used? Also, what about the inlet/outlet tubes on the Hall being too close to the back of the radiator to mount a sucker fan/shroud unit like I have now? My original radiator has been recored at least once and it appears the tubes were extended about 1"+ to accommodate the fans/shroud.

Most aftermarket rads have 1-1/2" straight stubs coming out of the core. Insert short pieces of 1-3/8" Gates Green stripe hose connected to 90 degree adapters with regular hose clamps. 90 degree sweat-solder copper tube fittings in the proper size work well. This allows you to space the 90 degrees out far enough to fit sucker fans. If your rad has formed stubs with 90 degree turns and you want to use the more efficient sucker fans in a shroud, cut the formed 90s off and insert short pieces of hose between the stubs and the 90s. Note- 1-3/8" rubber hose will expand enough with hot water to fit onto 1-1/2" stubs without much effort.

Part of the problem is, due to the body's low nose, the 16" tall Pantera radiator is shorter than- for instance- a 19" tall Corvette rad, both being 26" wide and both engines having similar power dumping about the same heat into their rads. If ANYTHING is off in your combination, many Panteras cannot cope with the smaller stock rad, at least at walking speeds. Once you're moving over about 30 mph, things work as DeTomaso planned. So we increase the water flow rate thru the system with a rad that has much larger tubes inside its core (1"-1-1/2" wide vs stock 3/8" wide), and use 2X or 3X bigger fans that suck 30mph air thru the entire core via a shroud, not just blow (less) air at two circles of the core.

You were asking about the backside on my black car and the water tubes. I have a ton of space back there as shown in the photo. The radiator has brackets welded on it to allow it to lay forward (sorry for the dust - proves I actually drive em haha). As far as brass vs aluminum, maybe you had a bad experience with the aluminum but I have the fluidine in my red 5S and a Ron Davis in my Group 4 for years with no issues (although I don’t do a lot of miles, but do drive in the excessive slow traffic Southern CA heat).

Ok, thanks guys. I have chosen to go with a brass/copper radiator because I'm not concerned about lowering weight and I like the ability to repair and recore in the future like the original. So it appears that no one makes one with inlets/outlets bent 90 degrees with enough clearance for sucker fans behind? I can see from the excellent photos that laying the rad forward isn't an issue, but I would still have to have the Hall rad inlet/outlets extended to fit sucker fans/shroud. If I decide to do the reverse and install new higher volume, more efficient pusher fans/shroud instead of the sucker fans/shroud can anyone vouch for the Hall being able to fit in place just like the original - without laying it forward? Same mounting points etc? Has anyone used the Brassworks radiator? If so, can you chime in on how it mounted etc? Thx

Garth posted an excellent reply about pusher fans in your previous cooling system topic (radiator looks like it might blow) on January 2, 2018. Good reading.

https://pantera.infopop.cc/top...988#1598208419964988

Install 2 new pusher fans with new high volume blades as per Garth's post, install the Hall radiator sitting straight-up as designed. You can't buy a better radiator.

Paul,

The Hall brass/copper radiator will mount in the stock position.

John

I have had a Ron Davis triple pass aluminum radiator in my Pantera for over 20 years. It has shrouded sucker fans on the back and although the outlet is on the driver's side of the car and some modifications to the coolant pipes had to be made, it has done very well. Better than the two pass aluminum radiator that it replaced. Arizona desert tested with an accurate water temperature gauge!

Thanks to each of you! You are right George, I have talked to Garth live recently but had forgotten what a fine and informative post he wrote almost exactly a year ago. It's been a difficult and stressful year, but I think I can look forward to getting things off to a more progressive new year and I wish the same to all here! Thx.

The Flowkooler water pump arrived today and the SACC billet pulley arrived the other day - so now just need the new radiator, grommets and ? to disconnect the originals and replace. I got the bolt kit from Summit with the water pump and it came with two different gaskets (why?). When I installed the correct thermostat I installed it and the gasket using Permatex water pump & thermostat gasket maker #22071 per info from two mechanics and NAPA. I plan to use the same again for the water pump installation.

The first pic shows the water pump and the pulley together with the two gaskets. The gasket on the left looks like it fits correctly, not sure about the one on the right. The water pump has some scratches on the attachment face (see second pic for close up) but the pulley is a work of art! Nice job Scott!

Do I need to do anything with those scratches or will the gasket + gasket sealer be enough to not worry about them?

As I mentioned above, Steve W. told me not to install a pulley to move coolant faster through the radiator, but others here and Georges' excellent article on cooling suggest doing so and my inclination is to go with that advice. I have the pulley, but I don't have to install it - what do you say?

A paddle-wheel water pump will cavitate- generate bubbles- and stop pumping much water at some engine speed; street engines usually do so around 5000 rpm. Changing pulley ratios is common; smaller ones lead to 'overdrive'- pumping more at low engine speeds and not pumping enough (due to cavitation) at higher engine speeds. The old trick of clipping every other impeller blade off a stock pump moves cavitation to higher engine speeds, as does a larger pulley (underdrive). I've made a few pump pullies in several ratios for street machines that worked for their owner's purposes.

As for your small pulley, it's not much trouble to try it- only 4 bolts and maybe a vee belt; with your driving style and the roads around your area, it might improve cooling... or not. If it gets hot earlier than you can live with, just remove the custom pulley before you get boil-over. No one can really predict what will happen with any given car combination, but I wouldn't intentionally use a small pulley at long WOT Silver State events or at Bonneville.

Minor face scratches in a pump won't hurt anything; use non-hardening sealer like Permatex #2. Pressures are only on the order of 15-20 psi or less. Just be VERY sure the new pump is NOT designed to run on a late engine with a serpentine belt. Serpentine-belt water pumps are designed to run BACKWARDS compared to vee-belt pumps. Massive overheating will result from mixing this up regardless of your pulley ratio.

Thanks Bosswrench. The water pump is the Flowkooler 1648 mentioned in George's cooling system analysis sticky thread and by others so I believe it to be correct non-serpentine model:

https://www.summitracing.com/parts/bra-1648

and the Permatex is this one in the pic.

Summit sent the wrong bolt kit with the pump (for a Chevy with only 4 same length bolts) and are now sending the correct kit with 11 different length bolts.

I had a chance to talk with Tara at Hall Pantera today and they will be back in the shop on the 2nd if anyone is interested, and I also got a nice call back from Dennis Quella. If I change my mind and go aluminum I'll be ordering directly from him. I am hoping to follow up with Brassworks when they reopen to find out more info about their radiator which there is a link to elsewhere but I'll put here again for general purposes:

http://www.thebrassworks.net/s...rs/product_info.html

I'm not sure what:

"Its made with tellurium copper and highly elliptical staggerred tube design and serves as the mid engines primary heat exchanger."

means, but I intend to find out.

paulf posted:… I'm not sure what:

"Its made with tellurium copper and highly elliptical staggerred tube design and serves as the mid engines primary heat exchanger."

means, but I intend to find out …

Does anybody have any experience with the brassworks radiator? All I care about is that it doesn't leak, and looks pretty stock, since it's getting impossible to find good radiator re-builders. The Phoenix radiators are good at cooling, but both of mine leaked quickly, after a fix they still leaked!

rrs1 posted:Does anybody have any experience with the brassworks radiator? All I care about is that it doesn't leak, and looks pretty stock, since it's getting impossible to find good radiator re-builders. The Phoenix radiators are good at cooling, but both of mine leaked quickly, after a fix they still leaked!

Hey RRS1, can you provide any more info about your where/how your two radiators leaked/failed? Did you buy these new, direct from Hall? If so, how long ago? Any other information?

The diagrams show the water pump pipe going to the top of the radiator. Is that correct? On all of the old cars, the water pump connected to the bottom of the radiator. The thermostat hose would go to the top.

I see Pantera Electronics now offers a copper/brass radiator and fans, to compliment their cooling fan controller. If the new radiator is like their other products, it must be excellent!

https://www.pantera-electronics.com/radiator.htm

FWIW, many owners solve the 90 degree bend problem on their radiator in & out spigots with a pair of big sweat-solder copper fittings (that never rust) and two short straight sections of 1-3/8" or 1-1/2" rubber hose per bend. Using them also extends the crossover hose away from the core for sucker fan & shroud clearance.

The main advantage of aluminum rads (besides 1/2 the wt) is the 3-4X larger core tubes that hold more coolant and flow so much more- not possible with copper rads. The Pantera needs all the cooling help it can get since its stock engine produces as much power as a 350 'Vette but the stock rad is 20% smaller and 6 ft away from the heat source. Then we modify them for more power & torque....

Earlycat, the Blue and Red Owners Manuals show the water pipes plumbed both ways in successive factory manuals. It makes engineering sense to plumb cooled water to the bottom of a radiator so the rising flow can help chase air bubbles up & out instead of fighting gravity, but who knows what logic Ford/DeTomaso followed?

I once tried both styles on a 600 mile round trip, changing configurations mid-trip at a friends garage. I found zero difference + or - in terms of stabilized running engine temp, on our car at least. YMMV.

I judged them by weight. The heavy Hall lasts forever and makes turning better. Cools just fine. Replaced with a new Hall rad to utilize the original thermo switches for fans. Previous H had snap switches blocked off and manual fan switch firing both pushers. New Hall has larger fans but same crappy right angle fabbed hose necks. Nothing like a beautifully engineered part with two steps backward . Every 90 deg bend is detrimental to flow. Two 45's are better. Three 30's even better. A variable radius sweep, now you're back to beautiful. Besides, copper and brass are the MOST malleable metals and sexy as hell when hand finished. That's how I'd build it. Supplied with a nice clear finish. Make you paint it crappy black.

How much money you got?

The Pantera Electronics ad says "this is a customer supplied radiator". They take your unit and send it out to a radiator guy... Been there, done that...