Replies sorted oldest to newest

Hi - a very late response - When you did the rebuild did you have to replace the tiny retaining pins in the uprights base that contain the face washer from rotational movement on the lower pivot shaft? I have a couple that are pretty well gone and it appears that the only way of removal is drilling them out - they are well stuck in there. You cannot pull them out. Has anyone done this ? I have sourced new pins for the job .

I like the new face washers from Wilkinsons - they seem to have a high slip coating on the outside contact face of the washer which was not on the old hardware. Should reduce the rotational drag on the face retained face washers and the wear and tear on the retaining pins.

Write out 100 times -

I must not cure ceramic paint on rotor hubs in kitchen oven and stink out house

I must not cure ceramic paint on rotor hubs in kitchen oven and stink out house

I must not cure ceramic paint on rotor hubs in kitchen oven and stink out house .......!

@Percy posted:Hi - a very late response - When you did the rebuild did you have to replace the tiny retaining pins in the uprights base that contain the face washer from rotational movement on the lower pivot shaft? I have a couple that are pretty well gone and it appears that the only way of removal is drilling them out - they are well stuck in there. You cannot pull them out. Has anyone done this ? I have sourced new pins for the job .

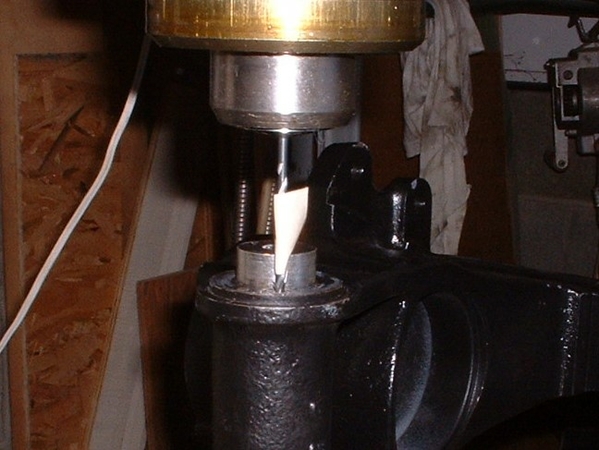

When I rebuilt my uprights, three of the four washers had been rotating and wore the pins down to nubs. I found the right-sized pins and had a machinist car buddy of mine drill holes for the new pins. I ground down what was left of the old pins and ground the new pins down to below the surface of the new washer.

Attachments

Thanks Lee - I was coming to a similar conclusion . In addition the new brass sleeves for the lower shaft are so very slightly larger than the center openings on the replacement face washers so they look like they will have to be fitted to the sleeves. My thinking was flatten the remains of the pins , fit the washer around the bushing and then use the retaining hole in the washer to locate the new pin position for drilling. Then the entire assembly should fit tightly.

There is very little latitude in this assembly area. It needs to be correct and functional.

Thanks so much Lee. Where else would you be offered such fantastic support on what appears to be such a small item. (not!).

I think I now understand why the pin just is not just drilled out . It appears to be of a harder material than the surrounding upright metal and if you should get on the edge of the pin the drill bit drifts off and you wind up with a hole partially in the pin and partially in the upright. Less than ideal and likely drilled not absolutely straight.

Just saying this because it once happened to a friend ......!