I've reworked my steering rack, getting it ready to install. I can't stop the leaks at the big end of the bellows. Everything is smooth & clean, new bellows, even put #2 permatex (non hardening) in to seal - and it still leaks. Any suggestions??

Replies sorted oldest to newest

Get rid of the oil and replace it with 0 weight synthetic grease.

Ron

^^ I second that!

I hadn't thought of that. Do I just grease the moving parts, bushings & bearings?

I disagree. In the only known factory manual on rebuilding our Cam Gears steering rack (Pantera Service Highlights, taken from the Factory Sales Guide), it specifically says, "DO NOT use grease in the steering rack; only 90-wt gear lube". The bellows act as a lube-pump to spread liquid lube back & forth across the whole rack's length, to assist the natural splash & flow of 90-wt during driving. All this flushes metal wear particles away from the open ball bearings on the pinion gear, and also lubes them. The corrugations in the rubber bellows trap wear particles.

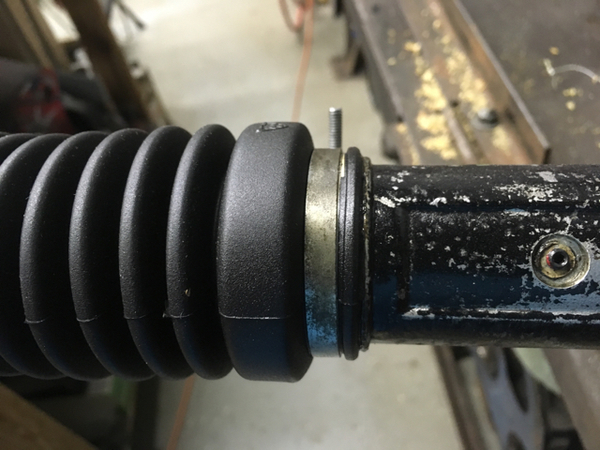

There are several sources of leaks. There is (or should be) a tiny fiber sealing washer under the little pointed-end screw that retains the rack bushing inside the body. The correct rubber bellows and special narrow clamps seal the rubber to the rack body so the bellows moves in and out in use. If a steering rod slides thru its bellows-end, the clamp is too loose and will leak. Shim or trim a stock clamp if it bottoms but still doesn't clamp tightly enough. Not all shops use the correct bellows or clamps, and I've seen shops use cheap plastic tie-wraps in place of the needed reduced-width metal clamps.

The cast-aluminum ends are shrunk onto a steel tube but I've not seen one leak there, even in an accident that bent the assembly (which can be straightened if not cracked). The pinion gear has a std. seal on one end, and a paper gasket sealing the pressure foot. I made a sight-glass from tygon tubing to see what the proper lube level was, and if filled to factory spec, the rack-gear is submerged to the bottom of the rack's teeth, including the pinion's tooth-mesh with the rack and the ball-socket steering rods. It also submerges the spring-loaded steel-to-steel pressure shoe on the rack gear's bottom, all for less steering effort.

If you add a bronze rack bushing (NOT sintered-bronze Oilite! It has low road-shock resistance and will pound out. I use aluminum-bronze) to replace a stock plastic rack bushing, be sure you deburr all the rack-tooth sides before reassembling. Burrs on the non-hardened steel teeth will ream a new bushing oversize and oval while you assemble it. A custom bronze bushing can be made 1-1/2 times stock length to allow more bearing surface, thus a bit longer life.

Boss,. Do you know the correct capacity if oil for the rack?

BTW. Clean everything with alchol5 or brake cleaner squeaky clean then, I'd try Honda (grey) or Chrysler silicone. Seems to work best for oil. It's our go to for potential problem gaskets. Coat the rack and let it skin over to the touch. Should fill any surface irregularities. Let it set at least overnight before you mess with it.

Cheers- J DeRyke

Thanks all - finally got it - after 3 tries. The two diamond shaped covers need a film of sealant, and one of the little bolt holes for them is NOT a blind hole. Teflon tape on the threads fixed that one. Get the boots and their seats squeaky clean, do one at a time, and let the sealant set up 24 hours before exposing to oil. I used #2 Permatex, I'm sure others would work as well.