quote:Originally posted by DOES 200:

Well, here is the first measurement on a brand, if anyone wants to add more brands. I measured one strut using my 4 post lift as a press with a scale under it.

Mighty-Lift D95004:

1" compressed = 96 lb

4" compressed = 105 lb

6" combressed = 108 lb

I did not put the Mighty-Lift on my car yet. I still have the Detomaso sold by many on my car, below is a link to the one from Wilkenson. I would be real interested in the pressure of these Detomaso struts.

http://www.panterapartsusa.com...l.cgi?prod_id=18126A

To continue with this post by adding more pressure measurements of other struts, I just measured the Detomaso 18126A brand from Wilkinson and here are the pressure specs:

1/2 to 1" compressed = 120 lb (this is what it took to make it start to compress).

2" to full compression gradually increased from the 120 to 160 near full compression.

My Autozone Mighty-lift 95004 seem to have given out, as now they hardly hold the hood up. I was thinking of putting Detomaso 18126A back on the car, so I decided to check the strut pressure again using the pressure from my car lift on the strut with bathroom scale under. As I lowered the lift and compressed the strut, the 120 lb to 160 lb as shown above was still valid. So if no one is experiencing issues with these shocks, then that pressure may be ok. I always hear everyone hype how these shocks release pressure when compressed, well that sure doesn't seem true on my testing. Maybe I am not testing pressure properly? I just lower my lift onto the shock and watch the bathroom scale numbers as I slowly lower the lift, what the hey!

quote:Autozone Mighty-lift 95004

My Autozone Mighty-lift 95004 were week this winter (after only about 6 months)...but seem to be satisfactory as the weather/engine heats up.

quote:week

weak

quote:Originally posted by TomCat:quote:Autozone Mighty-lift 95004

My Autozone Mighty-lift 95004 were week this winter (after only about 6 months)...but seem to be satisfactory as the weather/engine heats up.

It has warmed up here in CA and when running the car warm they do stay up just "almost", so I may just get another pair. Still debating the Detomaso 18126A, but I recall when on my car the pressure was even much greater when the car was run and engine bay hot (so with a hot engine bay, those pressure numbers shown above are probably much higher).

quote:Reply

I just replaced the AutoZone 95004 (blue sticker says 4490 0073) with the Sachs SG314002. The support seems fine.

Tom

Ps-Mine is a 73 with no wing, etc...

http://www.panteraparts.com/tricks/deck.html

Attachments

I contacted Wilkinson. Bill explined the NAPA shocks create the most pressure in the closed position. He said they have seen numerous deck lids damaged (bent) and deck lid hinges and pins warped with these shocks due the pressure exerted by the NAPA (Belcamp & Omni shocks). The shock (NAPA style)pressure is maxed in the closed position, exerting a constant amount of pressure on the deck lid.

Bill advised their replacemnt shock has the correct pressure and it is maxed in the open position. He also said he it will not make any difference on the NAPA shocks to have the piston up or down, same pressure.

Bill said a new deck lid is $5,400.00 !

I do not see any reason to screw around trying to save $45-50 and risk damage. I don't believe he would set any sales records for a pair of shocks costing about $90.00. I felt his advice was sincere. His also comes with the hardware.

We all like to save money but the possible consequences do not seem to be worth the risk.

They work great & i don't worry about bending the deck.

IndyDave

Attachments

quote:Originally posted by IndyDave:

Page 3, August 29, 2008:

I contacted Wilkinson. Bill explined the NAPA shocks create the most pressure in the closed position. He said they have seen numerous deck lids damaged (bent) and deck lid hinges and pins warped with these shocks due the pressure exerted by the NAPA (Belcamp & Omni shocks). The shock (NAPA style)pressure is maxed in the closed position, exerting a constant amount of pressure on the deck lid.

Bill advised their replacemnt shock has the correct pressure and it is maxed in the open position. He also said he it will not make any difference on the NAPA shocks to have the piston up or down, same pressure.

Bill said a new deck lid is $5,400.00 !

I do not see any reason to screw around trying to save $45-50 and risk damage. I don't believe he would set any sales records for a pair of shocks costing about $90.00. I felt his advice was sincere. His also comes with the hardware.

We all like to save money but the possible consequences do not seem to be worth the risk.

They work great & i don't worry about bending the deck.

IndyDave

IndyDave. I am not sure what the BS is with the less pressure in the closed position on those Detomaso shocks. I put one of those shocks on a press with a scale and the pressure is as indicated below (160 compressed), which is why I hesitate to use them. And these pressure are with cool shocks, you warm them up in a hot engine bay and it is much more. I hear 110 lb max is what it will take to not bend the decklid on shocks over time. If I buy them I wonder if they would guarantee decklid replacement, as that is where the rubber meets the road. Don't take my word for it, anyone buying them just put it on a press with a scale before you put it on your car and read what it says as you compress them.

Here are the pressure measurements I got on the Detomaso 18126A measureing one shock:

1/2 to 1" compressed = 120 lb (this is what it took to make it start to compress).

2" to full compression gradually increased from the 120 to 160 near full compression.

I may just end up going with a broom stick and be done with it.

I do appreciate you letting me know your measurements. Boom stick doen't sound too bad now.

Any idea of the cost for the IPSCO shocks?

Main page

http://www.ipsco.org/

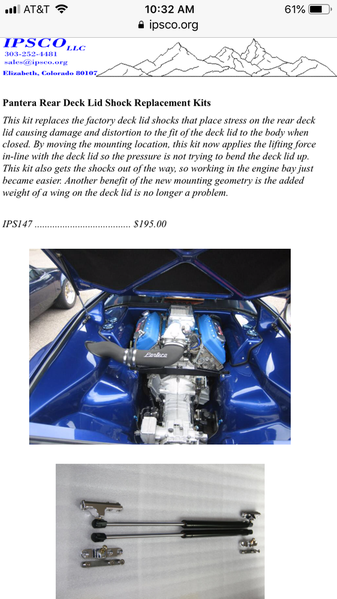

Rear Deck Lid Shock Replacement Kit

http://www.ipsco.org/Pantera%2...id%20Shock%20Kit.htm

Attachments

Attachments

quote:Originally posted by DOES 200:

Kind of interesting, Brad's blue car with the IPSCO set up seems to have lower hood extension than Dave's yellow car. Maybe they offer choices of different shock lengths. .....

I guess it depends on how closely you measure per the instructions. Placement of the anchor points will have a huge effect on the geometry.

Yea, you have to watch the pinch point between the decklid and the body when installing the kit.

Edit: I reviewed the installation instructions, and there seems to be a conflict on the placement of the upper anchor points. One page says 25" to the center of the ball, and one page says 25" to the first hole. I believe I placed mine at the latter, so that would move the ball further fwd, and raise the lid higher.

quote:Originally posted by Bosswrench:

FWIW, most Pantera vendors will not sell decklid shocks that compress with over 110 psi pressure, and even those are only for the heaviest wings. If your car needs more than a 110 lb shock (x 2), use the old reliable broomstick 'cause you really don't want to know what a bent roofline will cost to fix! The relatively cheap decklid is not what bends.... And the lower attach brackets are very difficult to repair with the engine and ZF installed.

Ha ha, that's a good one, when the vendors don't even know the pressures when you ask. I only find out when measuring them myself. I like the autozone Mighty-Lift D95004 pressure being under 110, but they don't seem to last too long maybe they are not meant for engine heat.

I originally purchased a strut from Strongarm that was cross referenced from another brand recommended on the Forum. It was way to strong for a non winged car. I simply called the company (Strong Arm)and spoke with their tech rep. He had a listing of all their strut's pressure, extended lengths and mounting methods. We walked through the alternatives and found the correct application.

quote:Originally posted by Corey Price:

So what's wrong with just cutting a piece of PVC pipe to fit and using it as a stop on each side with the original shocks? I guess I've read the whole thread and have no idea which shocks to get now. I'm just as confused as when I started to read it. The opinions and experiences are all over the place.

Ha ha Corey, this is what it is about when non-stock items are no longer avaliable, hunt and pick, trial and error. PCV vs Wood Stick, hum...I prefer wood. I wouldn't mind getting the autozone mighty-lift again, but since they don't seem to last, I found it somewhat risky changing these all the time as the brackets tend to bend somewhat on the car when taking out the bolts even if I support the hood real well...ouch!

To me, it seems like the Mighty-Lift and Strong Arm are probably the same manufacturer, but different label. See links below, exactly same specs. At least I see autozone now lists the pressure (80lb), damn first time anyone has listed the pressure rating. Although when I measured mine in a press I got:

Mighty-Lift D95004:

1" compressed = 96 lb

4" compressed = 105 lb

6" combressed = 108 lb

Mighty Lift D95004:

http://www.autozone.com/autozo...?itemIdentifier=1029

StrongArm #4490:

http://shop.advanceautoparts.c...ncode=22-109751138-2

Attachments

Before drilling holes in your Pantera,THINK WITH YOUR HEAD, measure 10 times - drill once - COMMON SENCE SHOULD PREVAIL!

Dam thats a bad ass blue pantera - who's is that?

Attachments

I'll let everyone know should the Strong Arm struts fail over time. So far, so good.

quote:So what's wrong with just cutting a piece of PVC pipe to fit and using it as a stop on each side with the original shocks?

That is basically what I did... I installed the Autozone shocks on my car and noticed the Carbon fiber was warping under the constant closed pressure.

So, I drilled small little holes at the bottom of each shock to let all the pressure out.

I have tiny little clips that I snap into place when I open the hood. I drilled a small hole through the shaft that I put a pin through to hold the hood open. Zero pressure and doesn't look so low tech as a broom handle...

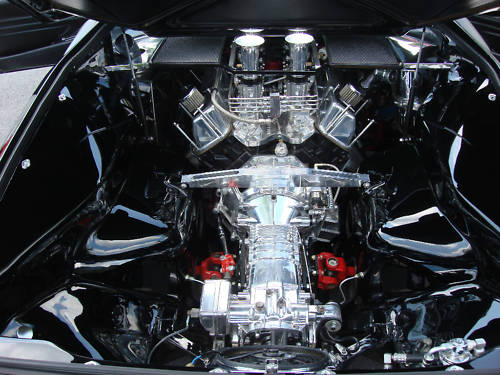

I like your engine bay!!!

quote:Originally posted by Z06 Pantera:quote:So what's wrong with just cutting a piece of PVC pipe to fit and using it as a stop on each side with the original shocks?

That is basically what I did... I installed the Autozone shocks on my car and noticed the Carbon fiber was warping under the constant closed pressure.

So, I drilled small little holes at the bottom of each shock to let all the pressure out.

I have tiny little clips that I snap into place when I open the hood. I drilled a small hole through the shaft that I put a pin through to hold the hood open. Zero pressure and doesn't look so low tech as a broom handle...

Not a bad idea drilling the shaft and using a pin to insert and hold up the hood. I bet it was hard gettig through that shaft and getting it just right. O shock pressure on a carbon fiber hood would be easy to raise the hood, but the metal hoods are kind of hefty unless you are Arnold Schwarzenegger. Maybe on the metal hoods don't drill out the bottom to still have a little pressure to help, and keep that shaft hole small as metal hoods are pretty heavy.

Attachments

Part# Ext Comp Stroke Shaft Body Force

D95004 17.18 10.96 6.22 8 18 88

D95957 17.26 11.04 6.22 8 18 125

D95148 16.77 10.34 6.43 8 18 149

D95060 16.77 10.34 6.43 8 18 106

Oh, I'm sorry, it is not on the screen, we can't help you!

quote:Originally posted by IndyDave:

YEAR, MAKE & MODEL PLEASE?

Oh, I'm sorry, it is not on the screen, we can't help you!

Ha ha yeah, real helpful company. However the new D95004 are working perfect so far, we will see if this pair lasts.

quote:Originally posted by Bosswrench:

Mr. 200, try mounting your deck shocks upside down. This puts the seal at the bottom and although your experience indicates the seals are below par, this might help extend their life a little. We used to do this with stock deck shocks for a different reason: the big stockers had a loose fitting boot on top along with a lip that tended to collect rainwater under the boot, which then rusted the shock top. If the big stockers can be mounted upside down, surely the small aftermarket shocks will fit.

My car doesn't see rain so I am not sure if that would change things fitting them the other way. But I was wondering if heat was ruining them, as on the package it says avoid heat. So when just tooling around town I put on a heat wrap tube and so I will see how this works over time. I recall these used to get real hot without the wrap, so I will see what happens.

Ordered a set of Sachs from PepBoys - will try those.

quote:Originally posted by Panterapatt:

Just bought a pair of Autozone Mighty Lift struts - p/n D95060. Lasted exactly one week. They held just fine at install. closed the decklid. Came back yesterday, they can't hold crap. So much for that idea - they are going back on Monday. Autozone is crap.

Ordered a set of Sachs from PepBoys - will try those.

That sucks, especially since their chart shows the D95060 to be stronger than the D95004 which I have. Mine are still holding up fine. If you get a chance, maybe test the pressure if you have a jack or car lift (something with force to compress them on a scale...I used a bathroom scale under my car lift).

Attachments

quote:Originally posted by Panterapatt:

Took the "mighty-lifts" back to autozone and got a refund. bought a set of Sachs 003's. Holding so far, but not as strong as I would like. When Kragen was still in business, their Dorman brand made a good lift strut with life time warranty. Too bad. Jury is out on the Sachs. Will keep all updated.

Dude, before you put them on the car did you measure the pressure on the Sachs? I found 106 on the Autozone Mighty-Lift D95004 when I put them on my car, and that was for sure the sweet spot. Much more than that I understand isn't good, I even saw one car where the struts bent the roof in some strange manner.

Pantera-Pat, the stock struts had a boot and a raised portion of the strut. The boot was loose-fitting and water ran down the rod under the boot & collected at the raised part. Then it rusted. So, many old-timers started installing stock struts upside-down to preserve the strut seals. With the Chinese gas struts used nowadays and their more rounded seal ends, there's no particular advantage to mounting upside-down but the early mount is widely copied anyway. FWIW, the rod end unscrews on most, if you have blade-type (Hall) ends and need heim-joint ends.

We all like to save money but the possible consequences do not seem to be worth the risk; warped decks and damaged roofs, as Jack stated, among others. I was also one of you guys experimenting UNTIL I found out about the damage the NAPA, Belkamp, Autozone, etc, shocks could cause. I'm sure I spent way more than the $90 cost from one of our suppliers. Buy the $90 shocks from one of our suppliers and have some piece of mind and save the possible repair dollars. Go price a deck lid before you experiment!

Just my opinion.

No reputable vendor will never sell a strut that exceeds 100 lbs.? yea, am sure they are load testing each unit.

Detomaso 18126A pressure: 1/2 to 1" compressed = 120 lb (this is what it took to make it start to compress).

2" to full compression gradually increased from the 120 to 160 near full compression.

I will dig around & see what I can turn up from several of the suppliers, regarding compression. Let me know if you already have the information.

Dave

quote:Originally posted by IndyDave:

Jan,

I will dig around & see what I can turn up from several of the suppliers, regarding compression. Let me know if you already have the information.

Dave

Good luck, usually they don't know the pressures, and a few vendors I asked wouldn't even tell what their pressures were, like a big secret. That is why I measured my Detomaso 18126A and others myself.

Does One believe that Two aftemarket Cylinders 'Off the Shelf', would come Perfectly Matched?

Also, Instead of Air, Use Nitrogen! The design would never 'Die'!! When they get weak...pump them up! Hot Climate/Cold Climate; REadjust!! A Small 'Mini' Gauge could be mounted on Each Strut(or just One) to help Moniter the 'Health' of Each Cylinder!

Or do 'I' have to do IT? They would NOT come Cheap!...

quote:Originally posted by MARLIN JACK:

....

Or do 'I' have to do IT? They would NOT come Cheap!...

That would be one way .. but complicated. Not to sound like a pimp for the IPSCO setup, but the engineering elegantly solves the inherent geometry problem with the original design. Love the Italians, but A^2+B^2=C^2 was not in their vocabulary.

The Rod Goes DOWN, so the Piston and Seals Stay Covered with the Lubricating Oil!! And YES! It IS The Heat that Makes Them Fail; as well as the 'Reservoir' being on the Bottom. With NO Lubrication the Piston Seals Dry out, can't Slide smoothly, they tear...NO more Pressure! There's No Mystery Here! And there's always the Heat! Even the Most Expensive Cylinders can Only Handle 140 Dgrees F! How hot do these Struts get? What is the temp Radiating off the Heads and Headers in the Vecinity of these Struts? 250F, 300F Higher?

I just finished Researching what I would need to produce a Custom, Fully Adjustable 'Air Strut', Specifically for the Pantera, and Only the Pantera! They are Perfectly 'Doable', But I would have to get $200. Each for them. And then they could only handle 140F Max.

I could Machine and build them from scratch, but the Piston 'Seal' would be 'Iffy'! and the cost would be Astronomical! Over the Cheaper Struts, there would never be a Market for Them!

My Advice is, if You mount them with the Rod Up, Expect them to Fail a Lot Sooner!! And even With the Rod Down, Sooner or Later, the Heat WILL Kill them! I suppose one could wrap a 'Ice-Pack' around them; or Install AC Onto them!LOL

Well, just use a Broomstick for a Hood-Prop and stop throwing Money away on Taiwanese Junk!LOL...

quote:Originally posted by MARLIN JACK:

...I thought We decided on the Correct Orientation of the Strut a Long Time Ago!!

The Rod Goes DOWN, so the Piston and Seals Stay Covered with the Lubricating Oil!! And YES! It IS The Heat that Makes Them Fail; as well as the 'Reservoir' being on the Bottom. With NO Lubrication the Piston Seals Dry out, can't Slide smoothly, they tear...NO more Pressure! There's No Mystery Here! And there's always the Heat! Even the Most Expensive Cylinders can Only Handle 140 Dgrees F! How hot do these Struts get? What is the temp Radiating off the Heads and Headers in the Vecinity of these Struts? 250F, 300F Higher?

I just finished Researching what I would need to produce a Custom, Fully Adjustable 'Air Strut', Specifically for the Pantera, and Only the Pantera! They are Perfectly 'Doable', But I would have to get $200. Each for them. And then they could only handle 140F Max.

I could Machine and build them from scratch, but the Piston 'Seal' would be 'Iffy'! and the cost would be Astronomical! Over the Cheaper Struts, there would never be a Market for Them!

My Advice is, if You mount them with the Rod Up, Expect them to Fail a Lot Sooner!! And even With the Rod Down, Sooner or Later, the Heat WILL Kill them! I suppose one could wrap a 'Ice-Pack' around them; or Install AC Onto them!LOL

Well, just use a Broomstick for a Hood-Prop and stop throwing Money away on Taiwanese Junk!LOL...

I figured maybe the heat is what was doing in my Autozone struts early. I did get some heat tubing wrap from Racing Sumit, which looks ok but I usually just slip them off at shows. Next time they fail I will put in the struts rod down, but so far with that heat wrap things seem to be ok.

quote:Originally posted by Dave2811:quote:Originally posted by MARLIN JACK:

....

Or do 'I' have to do IT? They would NOT come Cheap!...

That would be one way .. but complicated. Not to sound like a pimp for the IPSCO setup, but the engineering elegantly solves the inherent geometry problem with the original design. Love the Italians, but A^2+B^2=C^2 was not in their vocabulary.

The IPSCO system completely eliminates the problem with too much shock pressure and possible damage bending the decklid or hinges. There is no up ward force on the decklid or hinges at all when its closed. It all pushes straight back. I have a wing on my car and it raises nicely. Plus when its Going up at the end it slows down so it won't jar the decklid. I'm sold on the system.

Attachments

Detomaso 18126A pressure: 1/2 to 1" compressed = 120 lb (this is what it took to make it start to compress).

2" to full compression gradually increased from the 120 to 160 near full compression.

there are a couple of other options.

(1) Larry Stock is selling rebuilt oem struts, he's found a guy that can rebuild them.

(2) There was an article in a POCA newsletter a few months ago about using struts from the McMaster Carr catalog. I haven't seen them, but the McMaster Carr struts are supposed to look almost identicle to the oem struts.

quote:Originally posted by ZR1 Pantera:

Why not put the IPSCO setup on it and forget about it?

If function is more important than OEM look, there should not be any question about it.

IMHO I could add : They look much better than the original.

quote:Originally posted by Bosswrench:

Along with what George said, Ted Mitchell has been selling no-strut deck lid supports with flat coil springs for quite a few years, that look like Detroit hood supports from the '60s. They are properly weighted and are totally heat-insensitive, using no gas at all. Check his web site www.tmitch.com. Not cheap but quality never is.

Yeah, but I like the bone stock apperance on everything..he he

If no one has experienced ill things with the Detomaso 18126A, then I may just do those. Actually with all the talk about hoods and hinges bending, I have never actually personally heard of anyone that has had that happen, or any photos.

Thanks for the Mcmasters source too. In the link below there is quite a bit of offerings, and for once, someone actually posts lbs pressure.

http://www.mcmaster.com/#gas-springs/=lx99s6

quote:Originally posted by David B:

I've had mine for at least 15 years. They lift up the rear deck (with delta wing) with no effort from me at all. And it stays up. I can leave it open all day in the sun. They haven't lost anything in all these years. There's no brand name on them but I snapped this. I highly recommend them if you can figure out who's they are. I can't find any reference for that PN.

I just ran across this post.

RB8795148 is a part number but can't find the original manufacturer.

Tried Google'ing it and cross references to a 1978-1987 Dodge/Plymouth Hatchback.

Interchange Part Number: SG314005,4400,8195207,10368,8504IL,901210

Other Part Number: RB8795148,95148,613305

Sold in pairs.

The interchange part from Strongarm (PN4400)are sold in pairs for around $30 at The Lift Support Depot in San Marcos, California through their EBay store. Not sure what their normal price is.

Read some previous posts and decided to look around for new lid lifts. My existing units measured around 75 lbs when pushed against a scale and would not stay open.

Contacted Sacks and they identified several that were close to existing model.

Here's their reply;

SG314002 17.2" ext, 11" comp, 85#, 8mm eyelets

SG302001 17.4" ext, 11.5" comp, 85#, 8mm eyelets

SG314032 17.2" ext, 11" comp, 114#, 12mm eyelets

SG314003 16.7" ext, 10.25" comp, 121#, 12mm eyelets

These are the lift supports I have which closest fit your needs. You can purchase them at O'Reilly's Auto Parts, Pep Boys or Autozone. You can also find a wide variety of lift supports at www.liftsupportsdepot.com.

I purchased #SG314032 for my non-winged '72 Pantera. My deck lid has the dress up underside

so that does add a little weight.

These work perfect. Pop the hood and it raises by itself in a controlled manner and stays open. These new units are 115LBS, have the correct eyelet ends with slots that match my (i think) original double mount ends. Cost was around $23 each at O'Reilly.

Thank you for getting me on track.

Attachments

The ones that Hall sells as a non-stock replacement, when you cross the number over on the label, do show as that Dodge number. They also cost something like $28 each in a NAPA store.

I bought my first set from Hall. Installed them and the hinges where the attach to the decklid IMMEDIATELY pulled out of the decklid.

The only thing I could do there was braze them internally through the slit and they held. Problem is the heat warped that part of the lid.

I got that under control by shimming down the hinge mount flanges to the roof by 1/8".

I noticed that the deck was no longer pushing itself up, and was sliding down about 5 or 6 inches yesterday.

I have no wing.

I also think I see movement in the attachment of one of the hinges and the decklid.

There is NO visible rust on the decklid in the hinge area.

I haven't come up with a solution to this as I just noticed the entire mess yesterday.

Needless to say, I am not a happy camper.

I personally like the look of the original fat lift shocks.

I did hear mention that the rebuilt originals will not last for long. They seem to be a temporary solution as they quickly loose thier charge.

I personally can not verify that, since I have not gone that route.

I am going to an Italian Car day show today and will see if there are other Panteras there and what they have.

Any info on this I will post.

I am not sure how the factory originally attached these hinges to the decklid. There is no exterior evidence of that.

If the braze has not held, not sure where to go with this. Doesn't look like they can be converted to bolts.

Not a good scenario all in all.

I saw one car that has electronic lifts like on the current mini-vans. It works nice and he had it tied electronically to his key fob. I'm not sure if in the case of some type of an electronic failure the deck can be lifted manually or not? Pantera-electronics, i.e., Jon Haas has a design he makes that need an air compressor to work. I have a set here.

The issue that I have with that design is that the struts are larger in diameter then the replacement struts. That puts them too close to a couple of the tubes on my headers.

The other thing is that I'm out of room to put another compressor gracefully in the car.

I'm trying to encourage Haas to build a set of the self powered struts but as always with him, he looks at marketability and what he already has done so there is little hope there.

Every so often I look for electronic struts that would just happen to fall into a direct replacement scenario but so far the Pantera ones are too short to match anything currently in production. Of course there is always the possibility that one of the exotic companies will make them for a reasonable price of $1,000 each? For that probably the polarity will be wrong and you will probably need to rewire the entire car to make them work for sure?

quote:The ones that Hall sells as a non-stock replacement, when you cross the number over on the label, do show as that Dodge number. They also cost something like $28 each in a NAPA store.

I bought my first set from Hall. Installed them and the hinges where the attach to the decklid IMMEDIATELY pulled out of the decklid.

The only thing I could do there was braze them internall through the slit and they held. Problem is the heat warped that part of the lid.

I got that under control by shimming down the hinge mount flanges to the roof by 1/8".

I noticed that the deck was no longer pushing itself up, and was sliding down about 5 or 6 inches yesterday.

I have no wing.

I also think I see movement in the attachment of one of the hinges and the decklid.

There is NO visible rust on the decklid in the hinge area.

I haven't come up with a solution to this as I just noticed the entire mess yesterday.

Needless to say, I am not a happy camper.

I personally like the look of the original fat lift shocks.

I did hear mention that the rebuilt originals will not last. They seem to be a temporary solution as they quickly loose there charge.

I personally can not verify that, since I have not gone that route.

I am going to an Italian Car day show today and will see if there are other Panteras there and what they have.

Any info on this I will post.

I am not sure how the factory originally attached these hinges to the decklid. There is no exterior evidance of that.

If the braze has not held, not sure where to go with this. Doesn't look like they can be converted to bolts.

Not a good scenario all in all.

All of this is easily solved once and for all with a pair of IPSCO units. But alas, they are not in the stock location (because they are engineered to be an improvement).

From these past posts - most thought 90-100 lbs per strut would be perfect. The Sachs unit I purchased bolts right up and have 115 lbs for $23 each. I can lower the lid with one strong finger.

Best to you and the board.

Cylinders are operated by an air pump with a hidden switch in the license plate recess.

He doesn't market the thing but maybe with enough, "hey Jon?" inquiries he would make some?

quote:Originally posted by weber69:

DOES 200, We spoke after I bought my Pantera about 5 years ago. So how many Pantera's make a decent retirement fund?

From these past posts - most thought 90-100 lbs per strut would be perfect. The Sachs unit I purchased bolts right up and have 115 lbs for $23 each. I can lower the lid with one strong finger.

Best to you and the board.

Haha Weber, there is never enough for retirement, although 3 is getting close. I went to the web on yours, but they show 125lb. shown below.

http://www.liftsupportsdepot.c...mbers=SG314032&pns=1

Are yours still holding up? Nice engine bay by the way! The wife says I don't remember important things anymore, but I think your car was a real nice GT5 build.

Good options from others too, but I want something in the stock bracket position unless I cut off the brackets and repainted.

quote:Originally posted by DOES 200:quote:Originally posted by weber69:

DOES 200, We spoke after I bought my Pantera about 5 years ago. So how many Pantera's make a decent retirement fund?

From these past posts - most thought 90-100 lbs per strut would be perfect. The Sachs unit I purchased bolts right up and have 115 lbs for $23 each. I can lower the lid with one strong finger.

Best to you and the board.

Haha Weber, there is never enough for retirement, although 3 is getting close. I went to the web on yours, but they show 125lb. shown below.

http://www.liftsupportsdepot.c...mbers=SG314032&pns=1

Are yours still holding up? Nice engine bay by the way!

Good options from others too, but I want something in the stock bracket position unless I cut off the brackets and repainted.

Jon Haas's set fits right into the original brackets. No repainting needed.

The original fat dust boots fit right on.

The only difference is he left his natural machined aluminum.

I saw it yesterday but took no pictures.

I do believe that he has a video of them on his Pantera-Electronics web page? Take a look.

He hasn't answered me yet as to whether on not I can get a set from him. Soon.

http://www.oreillyauto.com/sit..._-1&keyword=sg314032

Here's their web description.

Sachs Stabilus - Lift Support

Part Number: SG314032

Line: SAC

Limited Lifetime Warranty

UPC: 19495086277

Compressed Length (In): 10.965 Inch

Extended Length (In): 17.185 Inch

Lower Mount Type: Eyelet

Travel Length (In): 6.220 Inch

Upper Mount Type: Eyelet

Detailed Description

Manufactured to automotive O.E. performance and quality specifications. Restores the original opening and closing speeds of your hood, hatch or trunk. Easy to install. No special tools required. Exact replacement, engineered for your application. Rust-resistant piston rod extends product life. Easy lifting, reduced closing effort. Consistent lifting force through 50,000 cycles.

Additional Details

Color: Black

Compressed Length (mm): 278.511mm

Extended Length (mm): 436.500mm

Hardware Included: No

Pounds Of Force (Lbs): 115 Lbs.

Rod Diameter (In): 0.315 Inch

Tube Diameter (In): 0.748 Inch

Type: Gas

Regards

quote:Originally posted by weber69:

DOES - Here's O'Reilly link for the Sachs lid lifts.

http://www.oreillyauto.com/sit..._-1&keyword=sg314032

Here's their web description.

Sachs Stabilus - Lift Support

Part Number: SG314032

Line: SAC

Limited Lifetime Warranty

UPC: 19495086277

Compressed Length (In): 10.965 Inch

Extended Length (In): 17.185 Inch

Lower Mount Type: Eyelet

Travel Length (In): 6.220 Inch

Upper Mount Type: Eyelet

Detailed Description

Manufactured to automotive O.E. performance and quality specifications. Restores the original opening and closing speeds of your hood, hatch or trunk. Easy to install. No special tools required. Exact replacement, engineered for your application. Rust-resistant piston rod extends product life. Easy lifting, reduced closing effort. Consistent lifting force through 50,000 cycles.

Additional Details

Color: Black

Compressed Length (mm): 278.511mm

Extended Length (mm): 436.500mm

Hardware Included: No

Pounds Of Force (Lbs): 115 Lbs.

Rod Diameter (In): 0.315 Inch

Tube Diameter (In): 0.748 Inch

Type: Gas

Regards

Well I've got the Sachs alright and 50,000 cycles? Come on. Maybe a couple of hundred then they're fashizille!

The deck is dropping down a good 12 inches BUT you sure can see them pushing the hinge up when it is closed?

I need my new electric cow bell. Can't wait until it gets here.

Hi Doug,

Sounds like you've been down this road a few times. DOES asked a question and I responded with the unit I recently installed. My previous units were a weak 70 lbs and couldn't keep it up. Some here mentioned the stiff 135 units were overkill. Some mentioned 90 to 100 lbs would be perfect. So I bought the SACKS 115 lbs units. They lift and close easy and I'm not seeing any lid bow due to compressed pressure. They are an exact fit to my original body hardware and cost $25 each delivered.

I also machined some SST end bushing that center position the units.

I'm a newbie and made the best decision based on this board of which you contribute some pretty good advice. I'm guessing I'll be addressing this again in a few hundred cycles.

I'll try to add a few pictures for fun.

Regards to all.

Attachments

quote:Originally posted by TomCat:quote:Reply

I just replaced the AutoZone 95004 (blue sticker says 4490 0073) with the Sachs SG314002. The support seems fine.

Tom

Ps-Mine is a 73 with no wing, etc...

So the AutoZone 95004s did a great job for about 4 years...now $22/side in 2015

The advantage with these is that when the deck lid is closed, there is ZERO pressure on the decklid. That's a big plus.

The other thing with them is that they work off of a dual frequency "remote". One frequency is for the door locks, the other opens the rear deck/trunk.

What's also neat about this setup is 1) it's very easy to install 2) the cylinders look just like the original Detomaso units with the accordian boots and all and they leave the original trunk lock in place.

The compressor is here, the hardware is here, I'm just waiting for the cylinders which are currently on back order from the manufacturer.

This is all ok since it is letting me catch up on all the yard work caused by this last nasty winter. It did a lot of little damage that went unnoticed because everything was buried in ice and snow for so long.

In the meantime, I need to replace the two Sachs struts that are in there now.

This is all ok at the moment. If it goes into June I'll start to get a little impatient with waiting.

mine are on their way out, but does stay up for now.

I don't want too stiff ( has a delta wing )

i do NOT want air or electric, has to be neat or invisible.

I thought I saw a chrome one on here, but can't find it.

At the moment a polished stainless slotted tube is winning this argument, but i don't have anywhere to store the tubes !

They are now finished and fitted and work a treat, if I push the rear hatch button the deck lid lifts then a gentle nudge send it slowly skywards until the struts are extended, and it stays there.

I bought 2 new struts the same length as my original ones, with the proviso that the ends must be removable, also the pressure within (Gained here on the forum) was 400newtons.

I removed the old rods from My original struts, had the tubes powder coated and new decals made up. Then the new struts were fitted inside the original strut tubes with a spacer at the bottom so the new strut sat in the spacer and was held centrally, The original top strut connectors were fitted to the new strut ends (using a helical) to keep them looking original.

The struts were £72 and engineering costs £20

decals free from my son in law and Powder coating £5.

they look well too see pics Hope this helps someone.

larryw posted:My ($175-total invested) rebuilt original struts failed completely Sunday. I went to a car show, raised the decklid, left it raised for the duration of the show, lowered it and drove home sixty miles in 95 degree heat. They acted just fine.

Next morning, both struts are totally dead. No push at all. Maybe the engine bay heat toasted them? Before all I had to do was push the button and the lid would gently rise all by itself. Now they resist my efforts to raise.

I'm not throwing any more $ at the originals. I did some searching around the forum for aftermarket recommendations and can't really find anything conclusive.

Is there anyone who's happy with whatever substitute they've found recently that they would pass along a recommendation on?

I've got a wingless lid.

Thanks in advance.

Mine were the same, So I fitted new much thinner units inside the old ones, only needs a couple of spacers main at your local machine shop, without a wing 400 newtons does the job. my old post is above sorry.

Attachments

IMNSHO the original design is poor because the lever arm from the hinge to strut attachment is too short. This creates all the sensitivity problems and high bending stresses on the hinge attachments. As has been previously mentioned, the problem is fixed by installing the IPSCO long shock kit with attachment points half way back on the deck lid. All the other non-original work arounds to use the same lid attachment point, I don't think are worth it. Of course, I don't think trying to stay with the original poor design is worth it either.

A site, www.panteraplace.com offers a considerable amount of "technical information", one category is "deck lid shocks" in which the SACHS SG314005 is suggested as a replacement to the original.

I presently have them on my car and am satisfied.

peterfenlon posted:After reading lots of good info here I wanted new struts my old ones were shot.

They are now finished and fitted and work a treat, if I push the rear hatch button the deck lid lifts then a gentle nudge send it slowly skywards until the struts are extended, and it stays there.

I bought 2 new struts the same length as my original ones, with the proviso that the ends must be removable, also the pressure within (Gained here on the forum) was 400newtons.

I removed the old rods from My original struts, had the tubes powder coated and new decals made up. Then the new struts were fitted inside the original strut tubes with a spacer at the bottom so the new strut sat in the spacer and was held centrally, The original top strut connectors were fitted to the new strut ends (using a helical) to keep them looking original.

The struts were £72 and engineering costs £20

decals free from my son in law and Powder coating £5.

they look well too see pics Hope this helps someone.

Hi Peter,

they look really nice. Would you by any chance have a file with the design for the decal you used, or perhaps a couple of extra decals you would be willing to sell?

Cheers, Tim.

My AutoZone D95004s just quit working this winter after 4 years. I found O'Reiley's had Sachs SG314002s in the warehouse. After putting on TWO SETS, it seems that they don't hold like they used too (maybe they have a shelf life as the packages looked OLD/dusty).

Anyway, I mixed and matched old and new and have the rear hatch satisfactorily lifted for now.

Is there a minimum pressure that should be able to hold a non-wing, 73 hatch? How can I test them (in my garage) before installation?

Thanks,

Tom

larryw posted:My ($175-total invested) rebuilt original struts failed completely Sunday. I went to a car show, raised the decklid, left it raised for the duration of the show, lowered it and drove home sixty miles in 95 degree heat. They acted just fine.

Next morning, both struts are totally dead. No push at all. Maybe the engine bay heat toasted them? Before all I had to do was push the button and the lid would gently rise all by itself. Now they resist my efforts to raise.

I'm not throwing any more $ at the originals. I did some searching around the forum for aftermarket recommendations and can't really find anything conclusive.

Is there anyone who's happy with whatever substitute they've found recently that they would pass along a recommendation on?

I've got a wingless lid.

Thanks in advance.

Over the years, I have tried just about all of the good as stock or better than stock replacement deck lid struts and never had any luck with any of them. They seem to work for a short time at least when it is warm outside, but rarely hold the deck lid up when it is cold. I don't have a rear wing on my car, but do have a rear deck lid liner kit, which hardly weighs anything. I currently have the SACC deck lid strut modification kit on my car and it works! The relocation of the strut mounts don't pose an issue for me and the two notches that are required in the back of the trunk liner are not a problem for me either.

I like the AutoZone Mighty Lift D95004...and they seem to last about 4 years. I have had a run of bad luck with (what looks like) old stock/shelf-life Sachs SG314002...so I am going back to AutoZone.

I just installed a new pair of AutoZone D95004s and they work PERFECTLY on a non-wing rear hatch...I'm happy!

Yes I was mistaken. The strut kit did come from IPSCO and it definitely works! I am sure that these struts would hold up a deck lid with a wing without any problem. You actually have to hold onto the deck lid when opening it to prevent it from slamming all the way open.

Yeah watch out for any struts that drive up the hood once you pop open the deck lid (at least those in the standard position). I believe I posted earlier on the struts marked “Detomaso” where I measured the pressure at around 170 or so (per strut) so I took them off. When I unhooked the hood with those the hood just flew open on its own. I also tried the Autozone a few times as mentioned here, but I gave up on them because I was only getting about one year on those before they went bad. On my last pair of those I even put heat insulation hose around them whenever I drove the car and they still failed. The last pair of trusts I tried were from Pantera Parts Connection part #18126p they and have worked 100% perfect since my purchase 4 years ago. The pressure on these are so spot on accurate that when you pop open the deck lid you can guide the deck lid open and closed with the effort of a finger or two. They are actually a little thinner than the Autozone too. On these I also slip on the heat protector tubing when I go for a ride and have some insulation tubing from Home Depot I put on the outside to keep the heat protectant tubing in place. Without that heat shield in place the struts get so hot that you can hardly touch them but the heat tubing seems to reduce the heat some (although not entirely). I am not sure if this shield helps with longevity but I found struts are not easy to replace in a one person job, so I use them anyway whenever I remember to slip them on. Here are some photos.

Attachments

Just chiming in to say what a great improvement the IPSCO replacements are over the stock design. I am not an originalist at all costs, especially for safety and functionality.

Hi all,

I am wondering if anyone can explain how to take the original deck lid struts apart.

Thanks, Tim

Just thought I would share that I had the original Pantera deck lid struts re-gassed for a very reasonable sum, and after fitting them, they seem to be working quite well. After looking around on this forum, I had them regassed to 425 Newton. I also chose to repaint them matt black and fit new stickers and rubber boots - they now look just like new. One interesting thing is that the usual wisdom is to fit them 'upside' down with the rod down, and this certainly allows one to show them off nicely when the deck lid is up (and the baggage carrier is in). However, on both sides the boot rubs on the weld on the wheel house when they are lowered- so this may be a good reason to fit them 'right side up'.

Cheers, Tim.

Tim,

Did you find our from your previous post how to disassemble the struts? And if so, could you elaborate? Also, how were the struts regassed and where did you have them done. Any info you could provide would be greatly appreciated.

Thanks!

Bill

I am interested in this also.

Hi Bill and RRS1,

I did not find out how to dissassemble them, but I guess after close inspection that the end, where the rod comes out of can be unscrewed with some kind of special tool. But I did not try to do it. Instead, seeing that the struts were still pressurised, but couldn't quite hold the deck lid open, and therefore the seals inside were probably O.K. I searched around for somewhere to re-gas them. Here in Denmark/Sweden, I couldn't find anywhere to do it by googling, in Australia there seems to be a place in every city, but a bit closer to home I found a place in England that seemed to be professional and would be able to re-gas them even though they are much larger in diameter than contemprary struts - it is SGS engineering, see here: https://www.sgs-engineering.co...s/re-gassing-service

If you are respraying them, then maybe wait until you get them back from them, as mine had a few scratches and nicks, after the proceedure and so I gave mine a final respray after getting them back.

Cheers, Tim.