Good lead Larry. Thanks .

My take away is:

1. When replacing the cable you must feed it from the engine side into the cabin to avoid damaging the carb end tube. Any decent mechanic would note that.

2. The bends the cable makes at the fire wall are well within the minimum allowable bend radius for a 1/16 in. cable. Not an issue.

3. The tube on the carb attach end is there to support the return spring when compressed. If you choose to remove the return spring support (tube) then ditch the spring because it's gonna get funky when compressed. Note, as posted in the previous thread the spring design does remove excessive wear from the carb throttle shaft and bushings. It's ( spring) selected for correct throttle peddle feel.

4. The return spring is opposing the cable so at full throttle (compressed spring) is the tension more than the cable design load ? Not sure but I doubt it. That's basic engineering if you have the required info. Do keep in mind that the cable core want's to straighten out ( go linear ) when under tension so there is wear taking place between the core and housing. Machines love lubrication so lube it. And remember that nothing last forever.

5. The weak link in the design is the cable attach at the engine. The cable must not only be properly aligned with the throttle attach at the carb it must be firmly attached to the cable bracket. Ours are not. And the bracket is attached to the engine with only one bolt. Not good should the bolt loosen allowing the bracket to move. Bottom line is the bracket sucks.

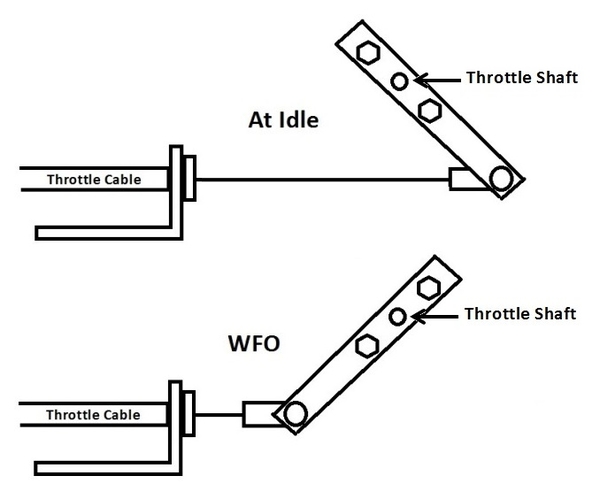

6. Last, to properly rig the throttle control you must adjust the secondary stops at the pedal. Must ! The primary full and idle stops are at the carb linkage. But if you don't have the pedal stops properly adjusted then bad things can happen. This is a somewhat educated guess on my part. I've spent a long time adjusting cables on aircraft so I think I somewhat ( for sure maybe ) understand them. My guess is to adjust the pedal stops to a clearance of .030 to .050 after the carb linkage stops have made contact. Maybe more but leaning to the safe side. The cable will stretch allowing the full throttlle stop at the pedal to be contacted. I noted knots tied in my throttle cable to shorten it and that someone had removed the full throttle stop (bolt) for the pedal. It's amazing the the cable never broke or the carb linkage was not damaged. Most likely saved by a light footed driver.

I did note that the cable was moving at the engine bracket causing a bind so I'm thinking about a better bracket. Thinking ... Ha Ha.

My 5 cents on Pantera throttle controls. Fire away guys .