All,

If anyone has a similar experience and/or can add any wisdom that I may be missing, it would be greatly appreciated.

Larry

All,

Replies sorted oldest to newest

First of all I do not have first hand experience with this cable. I did make a custom bracket to mount mine on the intake manifold side. If you were to some how extend the bracket, move it or make a new one that was 2" closer to the carburetor that would solve the issue if I understand the problem. It would also get the sharp radius bend away from the cable end which would probably make the cable operate smoother. My thoughts...

Here is the best picture I could find of the one I made. It was cut from a piece of extruded aluminum channel. It is set in a near stock position but I think I adjusted the height of the mount to better line up with the throttle body. Looking at the picture I can see that it is set back towards the cabin. Can your bracket be flipped around 180° to position the mount closer to the carburetor?

Steve

A simple fix could be to lengthen the cable a couple of inches at the gas pedal end using a coupling nut and threaded rod (cut to fit) .

Larry -

I don’t know about your specific cable, but John Taphorn has a design to reduce the bend radius on the intake manifold mounting point.

It’s very simple, just a bent piece of stock that guides the cable housing..... The bent stock is welded to the existing mounting bracket. I’ll try and find a picture.

i don’t think John’s mod would help in your case... I agree with you - it SEEMS LIKE the cable must be extended approx the same length as the housing for it to work properly.

Rocky - I am aware of John’s modification. Thanks but no photos needed.

Thanks for the feedback, guys. Only good news so far is that none of you have pointed out how blind I am to have missed some pertinent explanation of my problem.

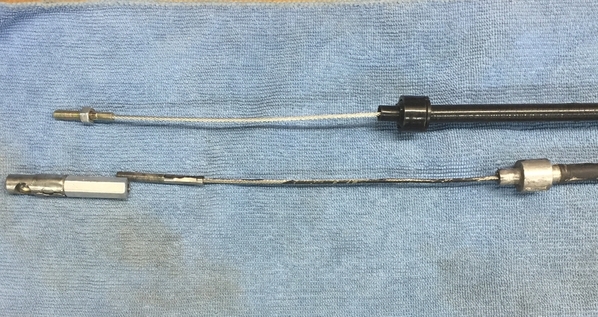

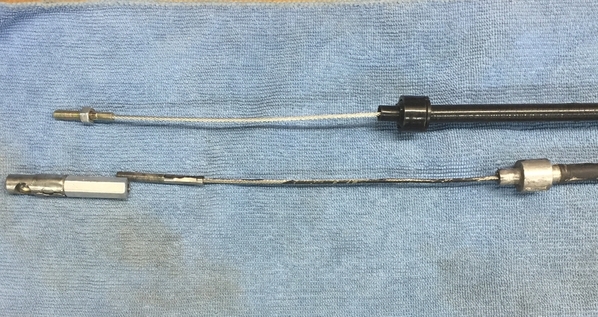

The bottom line is WHY is a part that is universal to all Panteras, successfully manufactured by Ford by the thousands, something a Pantera vendor seems to be unable to correctly reproduce?

Modifying the carburetor bracket would not solve the problem; there simply isn’t enough “free” cable at the pedal end of the assembly. Carburetor end of the cable is just fine. Modifying the center tunnel bracket would work, and using some coupler nuts would work.

But what doesn’t work is buying a reproduction part, only to find out it flat out will not work.

If I wanted a cable that doesn’t work I could buy one a lot cheaper at pick N pull.

Come Monday I will be calling other vendors to buy two or three more cables and see if one of them has actually figured out how to correctly reproduce a throttle cable.

Once I figure this out I will re-post; hopefully I will find at least one vendor that I can recommend to other owners.

Right now I have one that I certainly wouldn’t recommend.

Larry

Larry, you jogged my memory about a throttle cable installation that I did on my Pushbutton less than a year back. I ended up moving the bracket near the gas pedal to make it work. It looks you and I are two out 3 million that encountered this problem. Practically speaking, I only needed to drill a new hole for the screw that secures the bracket. But I was scratching my head as well as to why the cable did not fit out of the bag.

PM sent to Steve