Thanks

Thanks

Replies sorted oldest to newest

the amp gauge only shows the current in and out of the battery (excluding starter current).

So if you are running 100 amps worth of lights, radio etc that does not go through the gauge (IF the altenator is working)

I have been thinking similair, but more towards a "smaller" span gauge since battery charging is normally less than 20 amps. (and Limiting current draw prior to running)

Attachments

I always recommend to get a Volt Meter which is a much more useful Instrument. It tells you the condition of your electrical system. Just join the 2 connectors from the Amp Meter by attaching both of them to the + on a Volt Meter.

As suggested if you use a Shunt as a Jumper between the 2 connectors the only thing that will happen is that your Amp Meter becomes even more useless as it now stops showing the load on the Alternator too.

Btw to answer your question the OE Amp Meter will probably be able to handle your upgraded Alternator on a normal day. Just be aware that because of your upgrade the Alternator has the ability of a much higher output and it can potentially send 100 Amp through the Amp Meter under certain circumstances i.e. if you Battery was completely drained and you switch a lot of stuff on. That could become an issue!

Nevertheless I am still recommending to use a Volt Meter as it provides useful info as opposed to the Amp Gauge.

From the Autometer Web Site:

Link: Ammeter vs Voltmeter

WHICH IS BETTER FOR MONITORING A VEHICLE’S ELECTRICAL SYSTEM – A VOLTMETER OR AN AMMETER?

Short answer: A voltmeter, by far.

Electrical guru Mark Hamilton of M.A.D. Enterprises points out that amperage is a measure of current flow, so an ammeter is actually a “flow meter” that’s intended to measure current flow to the battery (under normal conditions) or discharge from the battery (in the case of alternator system failure). On a typical flow meter, all output must be directed through the device to obtain an accurate reading. In the ammeter’s case, that means all the alternator output used to recharge the battery must first be routed through the ammeter under the dash, which requires a heavy-gauge cable and presents a possible fire hazard. The ammeter itself must be able to handle all this current flow, so it must have a higher current rating than the alternator’s maximum rated output.

All this might be worth the hassle if the ammeter produced reliable information. But the ammeter can only measure the amount of current output to the battery for recharging purposes: When the alternator recharges a “low” battery, the ammeter indicates a high charge rate; with a fully charged battery the voltage regulator reduces alternator output, and the ammeter is supposed to indicate a very low charge rate. But how can you really tell the regulator has reduced alternator output because the battery is fully charged? Maybe a diode in the alternator rectifier failed, or the alternator belt slipped after it warmed up, just as if the battery were fully charged. Or maybe the meter indicates a medium charge rate most of the time-does the battery want this much or could the voltage regulator be overcharging the battery?

On the other hand, a voltmeter works like a fuel pressure gauge-but instead of measuring fluid in psi, the voltmeter measures electrical system pressure in volts. Just like a fuel pressure gauge, a voltmeter only needs to tap into a circuit; all the fuel (or electricity) does not have to detour through the gauge itself. Voltmeter installation is easy, quick, and safe: It hooks up to a fused, ignition-switched “off/on” source and does not require any modification of the circuit used to recharge the battery or any part of the alternator/regulator system. In short, the voltmeter installed at the dash will be a stand-alone circuit.

The voltmeter directly measures the result of charging-system performance. With normal alternator/voltage-regulator function, battery voltage is maintained at 14.0 to 14.5 volts-and this is reported directly by the voltmeter. In the event of alternator-system failure, voltage will be low and continue to drop as the battery discharges. In the event of an “overcharge” condition, the voltmeter will climb above its normal zone. In summary, there is no chance for misinterpreting a voltmeter’s readings as can happen with an ammeter.

Voltmeter vs. Ammeter?

AutoMeter offers both, but for most applications a voltmeter yields a safer installation while providing more useful information on charging-system conditions.

quote:Just join the 2 connectors from the Amp Meter by attaching both of them to the + on a Volt Meter.

If you do that, the voltmeter will be electrically hot all of the time (even with the key off), eventually draining the battery. The Cobra guys (and a few others) found this out the hard way.

John

quote:Sorry about this confusion

Not a problem. Just didn't want someone to end up with a dead battery.

John

quote:Originally posted by goodroc:

hmmmm, now I had to rewind my memory back 3 Years and yes I did in fact I did combine the 2 Connectors but I took the Source for the Volt Meter from a Switched + on the Harness..... Sorry about this confusion (mine)

I too installed a volt meter that was a close match to the Veglia gauges. The two connectors were joined on a small bolt with nut and jam nut. Be sure to insulate well the nuts and bolt. You do not want a piece of electrical tape to fall off from the heat and expose the connection. Grab a switched 12 volt wire and splice to the volt meter. DO NOT use the connections from the AMP meter.

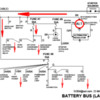

JB05177- Thank you so much for the simplified ampmeter electrical drawing posted above. I am in the middle of the last of extensive rewiring upgrades to 6997 and have had a few commissioning isolation gremlins - I think this simplified diagram has pointed me in the right direction to sort one of them out. Most appreciated.

Note to self - don't take a fully disassembled wiring harness , perform every upgrade known to man or beast and expect it to work first time .....!