http://www.youtube.com/watch?v=JRdwWgSGqvcWatch the top of the carbs in this video. Do you see the fuel mist coming out of the stacks?

That is the reversion caused by the overlap on the camshaft.

This video has a better side view of the reversion.

http://www.youtube.com/watch?v=caGWuuXqZq4It doesn't matter what carbs you use, it is the effect of an individual runner intake manifold that has no common plenum.

The Trans-Am Boss 302 with the dual Dominators does it, so does a Doug Nash with dual Autolite inlines.

If you put any kind of an air cleaner fabric over the stacks the fabric will be saturated not just by fuel, by atomized fuel.

The ONLY way with carbs not to have issue is run no fabric over them at all AND/OR use a camshaft that has something like 28-30 total degrees of overlap. That reduces the reversion to almost non-existant.

If you look at cam specs, that is very close to the stock 351-c Cobra-jet cam these engines came with new from Ford.

There are two 351c cam profiles I know of that are refered to as "Weber Cams". The one sold by "Inglese" is the Comp Cams version. Hydralic lifters, .586 lift, yada-yada-yada. The other is by Cam Techniques and is the virtually the same.

Look at the power numbers and the flow rates of the heads on these engines. You will notice that the engines start to make 500hp + with over 600 lift. Heads start flowing over 300cfm over 600.

The "Weber Cams" only start to approach this lift. The CJ cam isn't even 500 lift. It is 480 something.

Whiplash I think, is talking about the comp car he has? The factory comp cars ran 48IDAs. Holman-Moody solid roller lifter camshafts and were the same as the 4v Bud Moore race engines with his special "race plenum" intake manifold. (Ram boxes for lack of a better, or correct term).

The GT40 Mark I's ran 48IDAs Webers and the T/A Boss 302s, ran the dual Dominators on an IR intake "XE" manifold, have air chambers over them on which the mist accumulates like early morning due on the grass. All run with regular big overlap race cams. The 289 "LeMans cam" has 82 degrees of overlap. No special Weber cut cam there.

You need to keep the mist away from the headers and run no stack covers and you are generally ok with fire risk. I can tell you that you smell the gas when you come back off of the track OR back to idling with no motion after a flat out run.

The engine itself is going to have a shorter life span because of the cylinder washing from the volume of fuel being "dumped" into the engine. It doesn't matter if it is IDAs or IDFs. The end result will be the same.

Regardless of how clean you can get the carbs to idle and run, every time you mash the throttle, or even just move it, you have eight accelerator pumps jets doing their thing and the instantaneous black smoke from the exhaust is noticeable.

Interestingly enough, not many talk about the pump jets while tuning these carbs. I found that I could almost eliminate the pump shot (.050 vs stock .100) with no noticeable effect EXCEPT it made the cold engine very difficult to start without them.

The oil rings do not like it and you will build up a black film in the exhaust which is the engine oil you are washing out of the engine. It's the accelerator pumps doing the cylinder washing.

THEORETICALLY, you could reduce 7 of the pump jets to minimal except for 1 and use that one to start the cold engine...THEORETICALLY. I don't know how practical that actually is though. The engine is VERY easy to flood trying to start it cold if it doesn't fire up on the first crack of the key.

In addition, the air filters just make the engine harder to tune right and if you are going to do open track days then you take the filters off.

However, I do that even with the dual Holleys which seemingly adds 100hp to the engine at WOT.

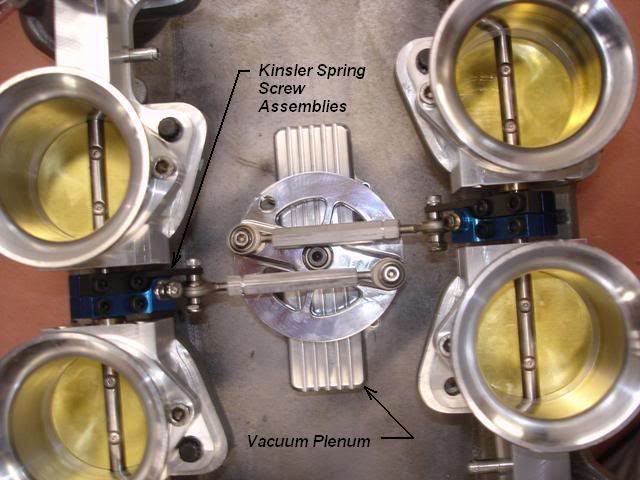

The only way to avoid most of these issues is to run IR EFI, as you mentioned. Then that's an entirely different animal, but they still will like to run around naked with no tops. Why not? I like to encourage that behavior as much as possible too?

The IDFs don't fix any of these issues. Most of the issues are created by using carburetors on an IR (independent runner) manifold. The IDFs just have a different idle system. Are you SURE they fit UNDER THE SCREEN? The front of the screen is very low.

Consider this...even if they fit.

Rule of thumb on any carb is you need a MINIMUM clearance over the top of the intake stack that is approximately equal to the OD of that stack, i.e., 48mm, 1.89". This includes air cleaners. Many of the air cleaners offered, simply stated are built WRONG for these carbs. Maybe they belong on your leaf blower but not on a Weber with velocity stacks.

The IDAs were run by some of the biggest race teams ever assembled, and some of the most successful too. There is a reason they were used, and there is method to the way they were applied. Think you are smarter then Fords GT40 program with unlimited budget? Really?

Want to duke it out with Phil Remington? Go ahead. Be my guest. I know better.

IDA's always pop at deceleration, not bad, but a sure characteristic that you are running IDAs. I would PRESUME the IDF's do also?

Running "Webers" is hardass. There is no way to pussyfoot around them. A love/hate relationship with Malaria type re-occurrances and Lord knows, psychotic masochistic undertones? But then again, you would probably only know this all from experience, are hopelessly addicted and understand that having the ultimate doesn't stop the desire for more. Frankly, it just never ends.

Oh..."your mileage may vary".

Gary

Gary