I have my Pantera 2881vin now for about 4 months and learning constantly and using this forum which is very usefull BTW.

I swapped my leaking master clutch cylinder, for a new one which I got through a vendor in the Netherlands. I did not change the slave cylinder or anything else. I have a system without the effort reduction kit. After mounting the new master clutch cylinder and bleeding the system, it turned out that there was not enough throw on the slave cylinder or distance which it travelled after maximum depressing the pedal to fully disengage the clutch.

Which is strange because before the swap the clutch disengagement worked well. It looks like the new master cylinder is not suited/compatible to the slave cylinder currently mounted. There were limited options to adjust the clutch system, basically only the distance of the clevis on the master cylinder rod. Started out with the same setting as for the old MC. Varying did not result in resolving the issue. There was not means to adjust the distance of the rod on the slave cylinder. It is not like it should be when looking at the parts manual and discussions. It actually has no means to adjust free play and is mounted horizontally.

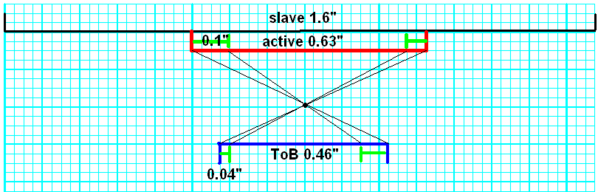

Now looking at my setup I see that it is certainly not stock and therfor I am assessing my options. see pic.

One of the parameters which would help me is to know what is the actual throw or distance the slave cylinder travels when the clutch pedal is fully depressed. When manually (with a big lever!) checking the disengagement of the clutch, I measured it to be around 1,5 inch ( one and a half).

I also read about a long throw slave cylinder. I guess this slave cylinder has a longer throw/distance it travels after clutch pedal depressing.

Does anybody have these figures available for me for both the stock and/or longthrow clutch slave cylinder? And can anyone explain the purpose of the long throw slave cylinder for me? Any other tips or insights?

Thanks in advance,

Joep