540 Rat's information makes me wonder if that Prolong stuff might be the hot tip for breaking-in a flat tappet camshaft. Who's gonna be the first one on the block to try it?

According to 540 Rat both he and D.Vizard are of the opinion that ZDDP is old school and there are better anti-wear agents available now such as calcium petroleum sulfontate used by the "Oil Extreme" company. But as I read the article the high ranking of the products manufactured by the "Oil Extreme" company made me wonder if the information may have commercial intentions. For now I'd give the guy the benefit of the doubt.

I agree with 540 Rat's comment that wear protection is not the only criteria in selecting a motor oil, but its possibly the criteria most important to most people. Wear protection is top on my list, but I also like to know how well an oil resists turning into carbon, in order to keep the ring grooves clean over the long term. This prevents the rings from sticking in the grooves, prevents oil burning, and keeps the engine running strong. When I was a kid Castrol was the top oil in this area, so it was popular for use in air cooled motorcycle and automobile engines. I also like to know how well the detergent package performs because I like the insides of my engines to remain clean like the day they were manufactured.

Since you're searching for a motor oil I'd like to contribute what I know on the subject of viscosity. No doubt the benefits of low viscosity oil are that it flows into clearances better and maneuvers within oil passages better too. However, oil viscosity is directly connected to the precision of the clearances in an engine. The issues are the taper and concentricity of the bearing journals and the bearing saddles. The ultra-low viscosity oil has benefits, but one drawback of ultra-low viscosity oil is that it cannot tolerate imperfections as well as higher viscosity oil. When the 351C was manufactured the 0W/5W oils were not available, and I doubt the engines could have been manufactured with enough precision in the machining process to use such ultra-low viscosity oil anyway. The 351C was original specified to use 20W40. I would not use 0W/5W oil in a 351C unless it had been re-machined to the precision required to use such ultra-low viscosity oil.

The 351C equipped with the factory crank and factory weight rods has an issue with insufficient rod bearing lubrication which is why fully grooved main bearings have always been recommended for the 351C; the fully grooved main bearings insure the maximum possible amount of oil is flowing to the rod bearings. However, the ultra-low viscosity oils don't have the same coherent oil wedge as higher viscosity oil, which is why fully grooved main bearings have fallen out of fashion for performance motors. A fully grooved main bearing has the same effect on ultra-low viscosity oil as the tire tread grooves in a rain puddle, it will channel oil away from the clearance between the crankshaft main journal and the bearing. Therefore if you're going to use 0W/5W oil in a 351C, use 3/4 groove main bearings instead of fully grooved main bearings.

One final drawback in using 0W/5W ultra-low viscosity oil in the 351C is that significantly more oil shall flow to waste in the clearances between the tappets and the tappet bores.

In spite of these drawbacks 0W/5W oil can be utilized successfully in the 351C. The prerequisites for using ultra-low viscosity oil in the 351C is precision machine work and tappet bore bushings. Rod bearing lubrication is significantly enhanced by the tappet bore bushings, this makes up for the 3/4 groove main bearings; the bushings also significantly reduce the amount of oil flowing to waste in the tappet to tappet bore clearances. I know a guy racing successfully with that combination in his 351C race motor.

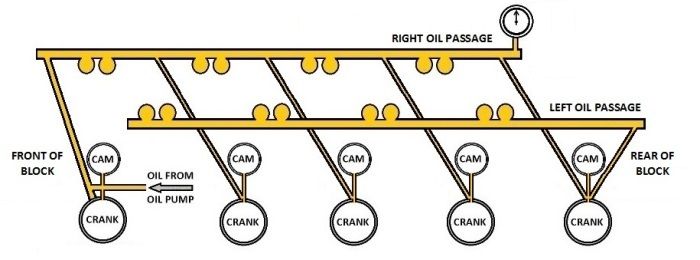

Notice in this picture of the 351C lubrication system that oil flowing from the front of the engine to the rear of the engine in the right hand oil passage must make 3 sharp 90 degree turns in the middle of the passage in order to flow to the 3 central main bearings. Low viscosity oil will negotiate those turns better than high viscosity oil, this "should" result in more oil supplied to the crankshaft bearings.

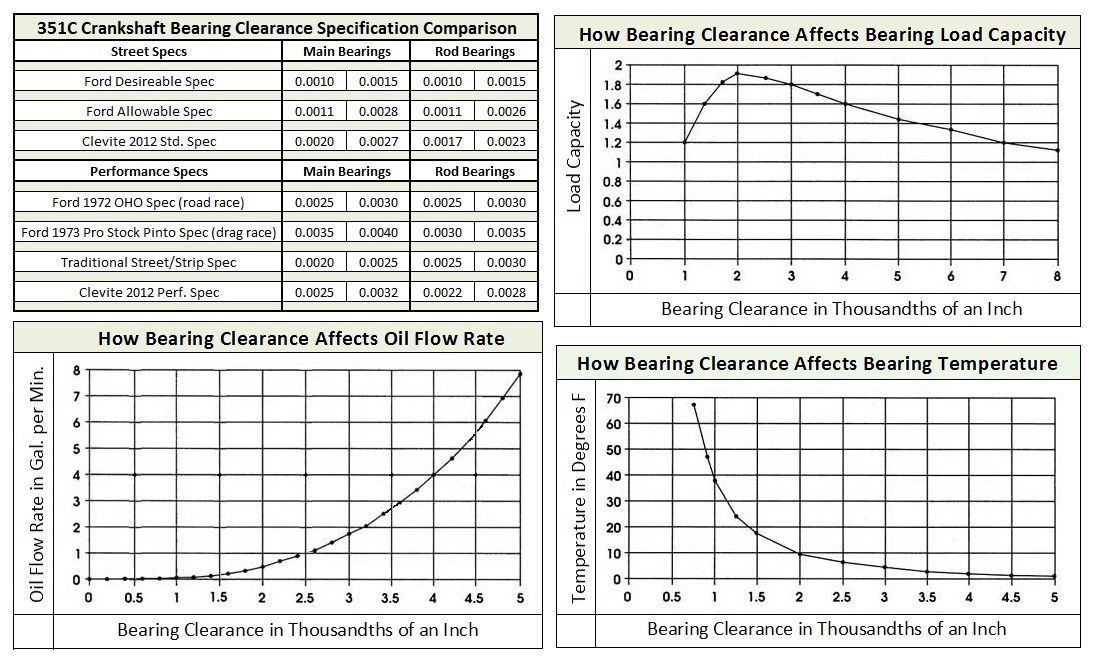

These graphs are designed around a 2.1" small block Chevy rod journal. Notice that a bearing clearance that is too small rapidly reduces the load bearing capability of the bearing, whereas a bearing clearance that is too large reduces the load bearing capability much more gradually. This why machining the bearing journals and the bearing saddles more precisely (less taper and better concentricity) does not necessarily mean its OK to use smaller bearing clearances. There is an ideal clearance in regards to optimizing a bearing's load capacity, but its better to have more clearance than optimum than it is to have less clearance than optimum.

Based on these graphs a clearance of 0.0010" per inch of rod journal diameter is about optimum in the small block Chevy. In the 351C equipped with the factory crank and factory weight rods it has been traditional to use a nominal clearance of 0.0012" per inch of rod journal diameter (0.0011" to 0.0013"), which is not extremely different. Keep in mind that the 351C rod bearings are a bit narrower than the small block Chevy rod bearings.

Also notice according to the graphs tighter clearances reduce oil flow and increase temperatures. When clearances are tightened-up, less oil flows into those clearances and therefore the bearings run hotter, because the oil not only lubricates, it cools the bearings as well. So while machining the journals and saddles more precisely is good, making the clearances tighter (smaller) must be approached with caution. If the clearances are tightened-up ultra-low viscosity oil becomes a necessity in terms of maximizing the amount of oil flowing into the bearing clearances, AND the use of synthetic oil becomes a necessity because of its superior resistance to break-down at high temperatures.

One last thing, notice that I've always qualified what I've written about the 351C by specifying the use of the factory crank and factory weight connecting rods. This is because the crankshaft material (iron verses steel), the finish of the journals, the counter-weighting, the balancing and even the effectiveness of the crankshaft damper all impact the crankshaft's needs in terms of main bearing clearances. The weight of the piston/rod assemblies and the drilling of the oil passages in the crankshaft also impacts the crankshaft's needs in terms of rod bearing clearances.

FYI I use 10W30 synthetic Valvoline VR1 (black bottle) in 6018's motor which is still using the 40 year old factory machining.