All Engine Projects

The 351C has 5 weaknesses that should be considered for all engine projects, even a simple rebuild. It is negligent and unwise to "rebuild" a 351C and not address these issues in the process, especially if the intention is to "uncork" the intrinsic performance of the engine as we are planning. These issues should guide a mechanic's decisions regarding what work to perform and which parts to purchase. And that's why I choose this topic as a starting place to embark upon a Cleveland engine project.

(1) The OEM Valves

• They were designed with a multi-groove spring keeper which Ford claimed is not suitable for high rpm.

• They are brittle, they develop cracks, and the heads fall off the stems from time to time, even at low rpm.

• The "Fix" is to replace the OEM valves with top quality single groove valves.

(2) The OEM Crankshaft Damper

• It is old, the rubber does not have the compliance it did when it was new, it does not perform as it was designed to perform.

• It is unbonded, if the ring hasn't already begun to move it shall eventually.

• It is made from iron, not the good SG (nodular) iron, just standard cast iron.

• It is too light for operation over 6000 rpm.

• The "Fix" is to replace the OEM damper with a new, heavier, fully bonded, all steel damper.

(3) The OEM Breaker Point Ignition

• The breaker points require periodic adjustment.

• The breaker points bounce above 6000 rpm.

• The ignition's output diminishes above 5000 rpm.

• The performance of the advance mechanism becomes erratic with age and/or mileage.

• The "Fix" is to replace the OEM distributor with a new or rebuilt breaker-less distributor.

(4) The OEM Connecting Rod Nuts

• They strip their threads at high rpm.

• The "Fix" is to replace the OEM connecting rod nuts with top quality ARP nuts.

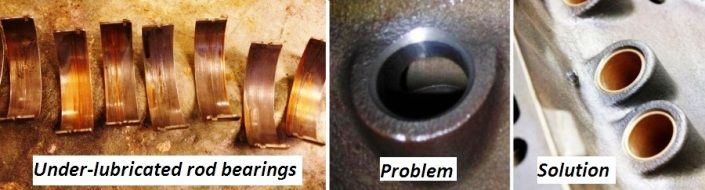

(5) The Lubrication System

The 351C lubrication system is notoriously problematic. Ford's hot oil pressure specification was 60 psi (+/- 10 psi) by 2000 rpm.

• The large "ports" connecting the tappet bores to the lubrication passages allow an excessive amount of oil to be wasted via the tappet clearances.

• The large "ports" connecting the tappet bores to the lubrication passages allows cavitation created by tappet motion to impede the amount of oil flowing to the main bearings.

• Impeding the amount of oil flowing to the main bearings results in providing insufficient lubrication to the rod bearings, and causes rod bearing wear and damage.

• Oil wasted via the tappet clearances and via the clearances caused by worn rod bearings over taxes the oil pump’s capacity making it impossible to achieve Ford's hot oil pressure spec.

• Oil pressure "sags" at high rpm for the same reasons.

• Oil not only lubricates bearings, it cools them as well. At some point above 7000 rpm the rod bearings fail completely due to under-lubrication. If complete failure occurs at 7000 rpm, then impending failure is occuring at 5000 rpm, and the precursors to failure are occurring at 3000 rpm.

• The large "ports" connecting the tappet bores to the lubrication passages create tappet compatibility issues, and often supply too much oil to the valve train. Under these conditions the oil pan can be "pumped dry" at constant high engine speeds.

• The "Fix" is to minimize the size of the ports connecting the oil passages to the tappet bores, via the installation of bushings with 1/16" orifices.

Extended Performance Projects

These issues should be considered for projects beyond a basic rebuild.

(1) The Cylinder Walls of the Production Block

• They are thin and they have a reputation for cracking under demanding use.

• The "Fix" is to install pistons with a "fully round" skirt design which spreads piston thrust forces over a wider area of the cylinder wall.

(2) The OEM Oil Pan

• The lubrication system cannot lubricate the engine unless a constant supply of non-aerated oil is delivered to the oil pump suction every moment the engine is in operation.

• The OEM oil pan is not designed for high G-Force maneuvers (braking, acceleration, cornering).

• Modern sports cars with the performance capabilities of the Pantera are equipped with dry sump lubrication systems.

• Unless you only plan to "cruise" in your Pantera, then you must consider installation of a wet sump style road race oil pan.

• The "Fix" is to replace the OEM oil pan with a high capacity road race oil pan, with baffles, scraper, and windage tray.

(3) The OEM Push Rods

• They flex at high rpm, even with the moderate force of the OEM valve springs.

• The "Fix" is to replace the OEM push rods with push rods made of larger diameter, heavier wall, seamless chromoly tubing.

(4) The OEM Valve Springs

• The valve springs are intentionally designed to allow valve float above 6000 rpm.

• The valve springs are not compatible with modern "high lift" camshaft lobes (over 0.500").

• The "Fix" is to replace the OEM valve springs with valve springs designed to provide higher force and to accommodate higher valve lift.

(5) The Balance of the Reciprocating Assembly

• The reciprocating assembly was "only" statically balanced by Ford.

• Vibration and harshness increase with engine speed.

• Increased vibration is destructive to the engine.

• Increased harshness makes it unpleasant to operate the engine at high rpm.

• Replacement of pistons or connecting rods will require rebalancing the reciprocating assembly anyway.

• The "Fix" is to dynamically balance the reciprocating assembly.

Dynamically balancing the reciprocating assembly not only improves the durability of the engine, it makes the engine more inviting to operate at higher rpm. It imparts a feeling of smoothness to the engine, a quality normally only found in high end, expensive automobiles.

Pantera Problems Impacting the Engine

There are two additional "issues" unique to the Pantera which impact the engine's operation.

(1) The Fuel Tank Outlet Tubing

• The metal tubing in the Pantera's fuel tank that supplies the fuel pump is only 5/16" OD; this is much too small.

• The "Fix" is to upgrade the size of the tubing to 1/2".

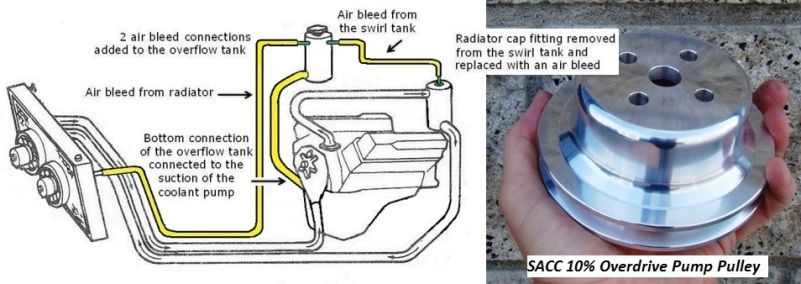

(2) The Engine’s Coolant System

The Pantera's coolant system is notorious for overheating at low speeds. There are 3 contributing factors.

• Air in the coolant system collects in the radiator, the cooling system has no functional air removal system.

• Coolant bypassed the radiator due to leakage around the OEM radiator’s vertical baffle (revised April 1973, approximately chassis no.5200).

• The coolant flow rate is insufficient, resulting from the length, diameter, and number of bends in the coolant system plumbing.

• The "Fixes" are to implement methods to positively remove air from the cooling system (manually or automatically) and to increase the coolant flow rate. Go here for more information: Engine Forum, Sticky #2

Resolving engine reliability issues and improving durability were the aspects involved in the recommendations above. Additional criteria involves "uncorking" the potential of the engine and enhancing horsepower. None of these methods for enhancing horsepower involve building a rough idling or temperamental race engine.

Primary Method- Optimizing Thermal Efficiency (improves BSFC)

• How well the piston rings seat and seal within their bores is the most influential aspect of an engine in term of making horsepower. You want to have the bore honed appropriately for the rings you have chosen and the oil you plan to use. The main bearing caps and head "torque plates" should be torqued to spec during the honing procedure. The rings should be hand fitted to the bores. Then they must be broken-in appropriately. Seek guidance from your piston ring manufacturer.

• Raise dynamic compression to between 7.7:1 and 8.0:1. This is a very important step towards achieving satisfying "seat of the pants" performance.

• Utilize a high output, dynamic dwell ignition; and have the ignition properly tuned.

• Utilize a carburetor with annular booster venturis; and have that carburetor properly tuned.

Minimizing Friction (improves BSFC)

• Piston ring drag on the cylinder walls is a major source of power-robbing friction. Modern thin piston rings are not only designed to seal better, they are also designed to reduce friction, via lower tension and reduced contact patch. The Ross pistons I've recommended below are designed for modern "thin" piston rings.

• The operating friction of engines utilizing the 3.5 stroke OEM crankshaft can be reduced by utilizing longer (351W length) connecting rods.

Uncorking the Engine's Intrinsic Volumetric Efficiency (improves VE)

• Improve low-lift flow by utilizing open chamber 4V heads, with a preference for the smaller valve D3ZE castings.

• Improve cylinder head performance, especially at low valve lift, via pocket porting, combustion chamber blending, and 3 angle valve profiling.

• Utilize high flow "racing style" intake valves.

• Utilize a camshaft which opens the intake valve earlier, having an intake centerline of 105° ATDC.

• Utilize a high lift but low overlap camshaft.

• Optimize rocker arm geometry.

• Select the 3.75 stroke crankshaft for a 7% increase in piston speed and 4.5% increase in gas velocity.

• Weld closed the exhaust heat cross-over of intake manifolds thus equipped.

• Utilize an intake manifold that performs better than the factory intake manifold.

• Utilize a carburetor of appropriate size for your intended VE.

• Utilize tubular exhaust "headers" of tri-Y or 4 into 1 design, and larger diameter tail pipes.

Note: The Advantages of Ross Pistons

• They are forged aluminum and very durable, they will tolerate cylinder imperfections, horsepower, and engine speeds that other types of pistons cannot.

• Their round skirt design improves cylinder wall durability.

• They are drilled for wrist pin oiling out-of-the-box.

• They are designed to utilize modern "thin" piston rings which reduce piston ring drag (less friction).

• Modern "thin" piston rings also seal better (improved thermal efficiency).

• They are available from Summit Racing at a FAIR price, including custom orders.

• Although there are pistons available for less money, none of them offer all of these advantages.

(351 or 357 cubic inches)

Reciprocating Assembly:

• Stock nodular iron 3.50 stroke crankshaft, 2.31 diameter x 1.66 wide rod journals, external balanced.

• Stock 5.78" heat treated 1041 steel I-beam connecting rods, stock 3/8 150,000 psi fasteners (1.65:1 rod length to stroke ratio).

• Replacement nuts for the connecting rods, ARP p.n. 300-8371.

• Ross round skirt flat top pistons 80556, 1.668 pin height, std. 0.912 wrist pin.

• Power Bond "Race Performance" damper PB1082SS, steel hub and steel ring, SFI approved, Fully Bonded, 28 oz. imbalance (made in Australia).

• Yella Terra steel flywheel (for long-style clutches) YT9902, 26.4 pounds, 28 oz. imbalance.

• Dynamic balancing.

• Cleveite tri-metal bearings, MS1010 mains, CB927 rods.

• Bearing clearances: 0.0025 – 0.0030 Mains; 0.0023 – 0.0028 Rods.

Notes:

• An upgrade from the factory connecting rod is the Eagle chromoly H-beam connecting rod, p.n. CRS5780F3D. It has a doweled big end, it uses 7/16 chromoly cap screws, and it is bushed for floating wrist pins. It is designed to use 351W bearings p.n. CB831. The rod bolts are torqued to 63 ft/lbs. It is rated for up to 750 horsepower. It is recommended when a solid tappet camshaft is chosen.

• An upgrade from the Power Bond crankshaft damper is a damper manufactured by BHJ Dynamics, p.n. FO-EB351C-7. It has a steel hub and steel ring, it is SFI approved, it is Fully Bonded, it weighs 10 pounds, and it is designed for 28 oz. imbalance. It is a top shelf damper. If you are planning on a solid tappet cam, and Eagle connecting rods, this damper shall compliment your choices (it costs about 3 times the price of the Power Bond damper).

• Another possible connecting rod and piston combination involves the 351W chromoly H-beam connecting rod manufactured by Eagle, p.n. CRS5956F3D. Like the 351C connecting rod it has a doweled big end, it uses 7/16 chromoly cap screws, and it is bushed for floating wrist pins. It is also designed to use 351W bearings p.n. CB831. The difference is its length, it is 5.956 inches long. Combine this with a custom ordered Ross piston having a 1.492 pin height (0.912 wrist pin diameter). With this combination the wrist pin is not pulled out of the bore at BDC as it is with the OEM combination, plus the rod length to stroke ratio is increased to 1.7:1, same as the 351W. This is considered the upper end of the optimum range, meaning this rod length to stroke ratio provides the least amount of cylinder wall thrust without impacting acceleration. A longer rod would decrease thrust even more, but it would also have a negative impact on acceleration. These two changes will lower the engine's operating friction, decrease frictional power losses, and increase horsepower.

Camshaft Timing Set:

Rollmaster CS3091, Ford Racing Performance Parts M-6268-A351, or Cloyes 9-3621X9.

Cylinder Head Option No.1: 1972 (D1ZE Castings)

• D1ZE open chamber 4V heads, 75.4cc chambers.

• If the intake valve throats remain at 1.75 diameter (this is the stock – unported dimension), sonic choke shall occur at 7300 rpm.

• Install Manley valves.

• Utilize head gaskets having 0.040 or 0.048 compressed thickness.

• The static compression ratio goal is 9.30:1.

Notes:

• 0.048 head gasket is for 4.030 bore & 9.200 deck, 0.002 deck clearance. Mill the heads 0.0025 (74.9cc).

• 0.040 head gasket is for 4.000 bore & 9.215 deck, 0.017 deck clearance. Mill the heads 0.016 (72.2cc).

• Intake valve, Manley Race Master, 2.19 diameter valve head, 5.24 length, 0.3415 stem diameter (11/32).

• Exhaust valve, Manley Severe Duty, 1.71 diameter valve head, 5.05 length, 0.3415 stem diameter (11/32).

Cylinder Head Option No.2: 1973/1974 (D3ZE Castings)

• D3ZE open chamber 4V heads, 78.4cc chambers.

• Upgrade the heads with 2.125 intake valves.

• Open the intake valve throats to 1.65 diameter minimum; at that dimension sonic choke shall occur at 6500 rpm.

• Install Manley valves.

• Utilize head gaskets having 0.040 compressed thickness.

• The static compression ratio goal is 9.30:1.

Notes:

• An intake valve throat diameter of 1.71 will raise sonic choke to 7000 rpm.

• For 4.030 bore & 9.200 deck, 0.002 deck clearance. Mill the heads 0.0095 (76.5cc).

• For 4.000 bore & 9.215 deck, 0.017 deck clearance. Mill the heads 0.031 (72.2cc).

• Intake valve, Manley Race Master or Race Flow, 2.125 diameter valve head, 5.24 length, 0.3415 stem diameter (11/32).

• Exhaust valve, Manley Severe Duty, 1.65 diameter valve head, 5.05 length, 0.3415 stem diameter (11/32).

(377 or 383 cubic inches)

Why I've Recommended a Stroker Engine

The additional displacement of this engine allows us to employ the D3ZE cylinder heads without having to mill them. On top of that the additional stroke provides 7% higher piston speeds and 4.5% higher gas velocities at any given rpm (based on a 1.77 diameter intake throat). Gas velocity in the 4V intake port is brought into the realm of modern engines. Combined with the 4 inch "open" combustion chambers and smaller valves of the D3ZE cylinder heads, this combination modernizes the 351 Cleveland. Higher piston speeds and the improved low-lift flow capabilities of the D3ZE cylinder heads combine to create an opportunity for increased horsepower across the engine's power band.

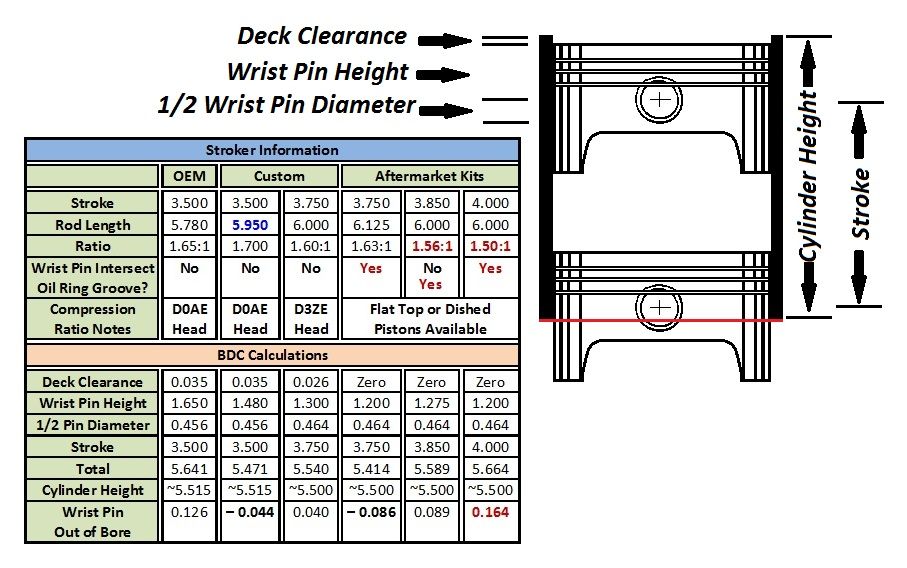

Stroker Kits

Most of the "stroker kits" available for the 351C are assembled around crankshafts having a 3.85 or 4.00 stroke, there are very few 3.75 "kits" on the market. Those 3.75 kits that are available stray from my instructions in two ways. (1) They have taken to using 6.125 length connecting rods, whereas 6.00 length connecting rods had been used in the past. This change in rod length was made as a convenience because it allows using the same pistons in the 3.75 kits as those used in the 4.00 kits. This of course means that the wrist pin shall intersect the piston's oil ring groove. (2) The second problem with all stroker kits is that none supply pistons with fully round skirts.

To build a 3.75 stroker as per my instructions shall require working with a crankshaft manufacturer to assemble a custom kit (reciprocating assembly) employing 6.00 length connecting rods and custom ordered round skirt, flat top pistons.

Reciprocating Assembly:

• Forged chromoly steel 3.75 stroke crankshaft, 2.10 diameter x 1.88 wide rod journals (to accommodate Chevy rods), internal balanced.

• 6" Chevy chromoly H-beam connecting rods (there are many choices so I'm not going to make a specific recommendation), doweled big ends, 7/16 chromoly cap screws, bushed for floating wrist pins (1.60:1 rod length to stroke ratio).

• Custom Ross round skirt flat top pistons, 1.30 or 1.32 pin height, 0.927 Chevy wrist pin.

• BHJ Dynamics damper FO-IB351C-7, steel hub and steel ring, SFI approved, Fully Bonded, 9 pounds weight, neutral balance.

• Yella Terra steel flywheel (for long-style clutches) YT9902N, 26.4 pounds, neutral balance.

• Dynamic balancing.

• Cleveite tri-metal bearings, MS1010 mains, CB826 rods.

• Bearing clearances: 0.0025 – 0.0030 Mains; 0.0021 – 0.0026 Rods.

Notes:

• 1.30 pin height is for 4.030 bore & 9.200 deck, 0.026 deck clearance.

• 1.32 pin height is for 4.000 bore & 9.215 deck, 0.019 deck clearance.

The 3.75 stroke crankshaft with a 6" connecting rod shall have a 1.6:1 rod length to stroke ratio, which is considered the lower end of the optimum range (1.6:1 to 1.7:1). The wrist pins shall not intersect the oil ring grooves. The wrist pins are pulled out of the bore at BDC LESS than they are with the OEM application. None of the rotating parts shall hit the block. The engineering is good, the engine shall be durable like an OEM engine, thus capable of lasting a long time.

Camshaft Timing Set:

Most stroker crankshafts have a "Windsor nose" but Cleveland main bearing diameters. To use a Cleveland timing set such as Rollmaster CS3091 requires a 0.375 thick (3/8) spacer for the crank nose. An alternative to the spacer is to use a timing set in which the spacer has been incorporated into the timing set's crank gear. Rollmaster makes two such timing sets, CS3130 which has a single Torrington bearing, or CS10065 which has a dual Torrington bearing assembly. If you are having a crankshaft custom made may I suggest instructing the crank company to give it Cleveland nose dimensions.

Cylinder Head:

• D3ZE open chamber 4V heads, 78.4cc chambers.

• Upgrade the heads with 2.125 intake valves.

• Open the intake valve throats to 1.70 diameter minimum; at that dimension sonic choke shall occur at 6500 rpm.

• Install Manley valves.

• Utilize head gaskets having 0.040 compressed thickness.

• The static compression ratio goal is 9.27:1.

Notes:

• An intake valve throat diameter of 1.77 will raise sonic choke to 7000 rpm.

• Intake valve, Manley Race Master or Race Flow, 2.125 diameter valve head, 5.24 length, 0.3415 stem diameter (11/32).

• Exhaust valve, Manley Severe Duty, 1.65 diameter valve head, 5.05 length, 0.3415 stem diameter (11/32).

Continued Below

.