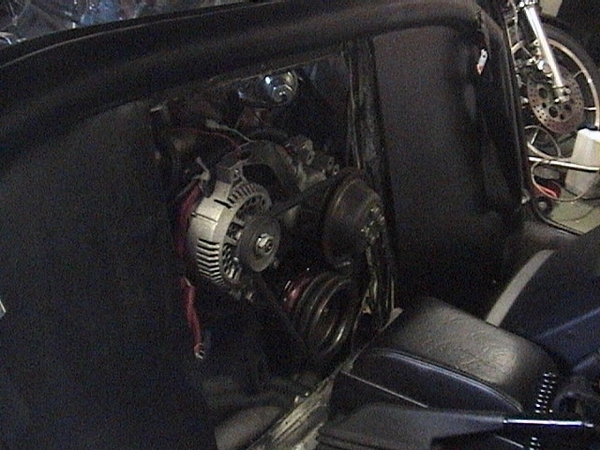

...What You call 'Perfect Alignment' is NOT!! 'Sighting-Down' does NOT Work! Even when we use our 'Good' Eye! Use a 'Straight-Edge' Bar, to Prove the Alignment of ALL the Pulleys!! The Adjustment Bracket is Bolted to the Rear of the Alternator on My own Engine, for a Perfect Alignment. Other Engines may be Different!! I am using the 100 Amp Alternator with the Internal Fan. This is a old photo before the 4.9" WP Pulley was Installed. I still say to use a 'Straight Edge' to Perfectly Align All Pulleys. Please see attached Photo.

Also, use Two Washers under the Bolt HEAD, the first on, must be as Wide as the Adjusting Bar, as a Load Spreader, and for High Friction/Grip! The second washer allows the Bolt to 'Glide' for Tightening. And remember ALL Washers are 'Sharp' Side Down! Don't ask Me Why...Just Do It! I have since gone to a Bolt Long Enough to protrude beyond the Boss, so I could use a Nylok Nut, and washer, on the End to LOCK the Bolt from ever Vibrating Loose. This in turn, saves the Need to Over-Tighten the Bolt and Strip-Out the Aluminum Threads! ALL of this is to keep the belt tension adjustment from SLIPPING. I use a 'rod' of wood (broom-handle does Not Mar) to apply 'Leverage' tension on the Alternator and Belt while tightening the adjustment bolt...Last tighten the 'Pivot/hinge' Bolt! TOO much pressure on the Belt will wear the Alternator Forward Bearing Faster! TOO little tension will allow the belt to slip and squeal. The Alternator takes up to 15-17 Horsepower and More, to run when at full charging. Use Your Head and don't over-tighten! In My view the Proper Tension is Correct when the LONGEST Span of the Belt can be moved by moderate force, a total of One Inch, 1/2 inch to each side, along the Axis of Rotation. NO More...NO Less!

...And Yes! Since you can see here there is NO more adjustment using the Stock WP Pulley, that when I installed the 4.9" Pulley, I Did have to go to a SMALLER Belt! The Newer Pulley did Not Change the Alignment. As far as the 'Crank' Pulley, Notice the Belt is on the Forward Sheeve. Lay the straight edge across both sides of the crank pulley, now angle the end up, and it will just touch the face of the alternator pulley, they are aligned! After Running-In a Brand-new Belt, a Re-Adjustment is Necessary, as it will wear-in and stretch somewhat, and may start to slip and squeal.

Good Luck with it!

MJ

...Now, go Buy My 8 Inch Wheels.