Breakerless ignition showed up in North American Ford vehicles in 1974. The first ignitions were not called DuraSpark; they were referred to as breakerless ignitions. The modules had a green wire strain relief with two harnesses, one connector with 3 pins, and one with 4 pins. I mention these modules just to make you aware of them; the Duraspark modules are more desirable for ignition swaps.

In 1977 Ford began referring to the breakerless ignitions as DuraSpark ignitions, and released two ignitions simultaneously; the DuraSpark I ignition for California, and the DuraSpark II ignition for the rest of North America. They referred to the Duraspark I ignition as the "high output" ignition, it was an entirely different ignition, not "just another Duraspark module". The Duraspark II ignition was just an upgrade of the breakerless ignition Ford had been installing in its cars since 1974. The DuraSpark I ignition was more sophisticated in its design, more expensive to produce, and capable of producing a stronger and more consistent spark under varying engine load conditions. Ford found this necessary to meet California emissions standards in 1977. Both DuraSpark ignition modules had two harnesses, one with a two pin connector, and one with a 4 pin connector, 6 wires in total. The earlier module with the green strain relief had 7 wires; it had a blue wire that was not carried over into the DuraSpark modules.

At the heart of the Duraspark I ignition was a special ignition coil having a very low primary winding resistance. The coil was also operated with no ballast resistance; therefore current flow in the primary windings was substantially increased in comparison to the primary current of Ford's standard (Duraspark II) electronic ignition system. The core of the coil was designed to accept a much higher magnetic charge from the increased current flowing in the primary windings, thus producing a substantially higher voltage to the spark plugs. The higher magnetic charge also allowed the coil to reach "full charge" more rapidly than Ford's other systems. Spark intensity was greatly increased ... especially at higher rpm. If this coil's primary winding was charged with the conventional "fixed-dwell" control utilized by the standard electronic ignition system it would overcharge at low rpm and overheat. Therefore an ignition module with a unique primary current control circuit was required to compliment this coil. Differing from the various Duraspark II ignition modules, the Duraspark I module didn't control charging of the coil in the conventional way. The Duraspark I module utilized dynamic dwell, meaning the module constantly adjusted dwell based on current flow in the coil's primary circuit, independent of engine speed. This prevented over charging or under charging the coil throughout the motor’s rpm range. Dwell therefore varied with respect to the degrees of crankshaft rotation but remained relatively constant with respect to actual coil charging time; and the coil was properly charged throughout the engine's operating range. The DuraSpark I ignition module had a red wiring strain relief. This ignition was only installed in California cars; therefore many hot rodders were not and are still not aware of its existence, or the difference between it and the DuraSpark II ignition module.

In 1978 Ford found it could meet California emissions regulations with the less expensive DuraSpark II ignition in all of its motors except the 302 V8. So California cars with the 302 V8 received the DuraSpark I ignition, and California cars equipped with all other motors got the DuraSpark II ignition like the rest of North America. The same applies to 1979 California cars. 1979 I believe was the last year DuraSpark I was installed in any Ford car. Worthy of mention is the safety feature built into the DuraSpark I module; if the distributor rotor is not turning, the module shuts off current to the coil primary, the ignition cannot fire, so it is safe to work on the ignition without fear of being shocked. NOT SO with any other Ford module. Disconnecting the wrong wire on any other Ford module while you are working under the hood can result in triggering the ignition and shocking you with enough current to stop your heart. No Kidding!

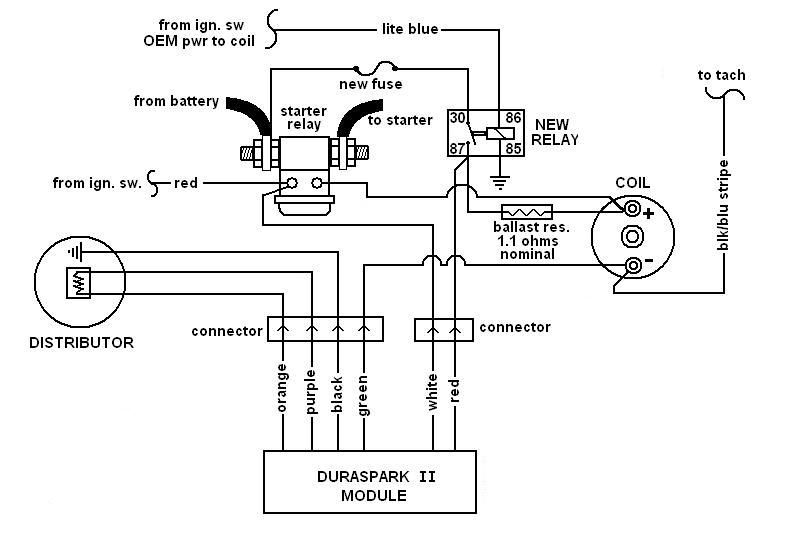

The DuraSpark II ignition module introduced in 1977 has a blue wiring strain relief. It is not much different from the early module with green wiring strain relief. Its reliable and provides a nice spark, but it is less sophisticated than the DuraSpark I. Current in the coil primary is controlled just like it was with a breaker point ignition, with a ballast resistance in line with power to the coil. Dwell time is also controlled the same as a breaker point ignition. To provide a hotter spark while starting the motor, there is a second wire supplying the coil that bypasses the ballast resistor to provide full battery voltage when the ignition key is in the start position. This module is the most common module for retro-fitting breakerless ignition to early cars, simply because many people are not aware of the existence of the DuraSpark I ignition, or they are not aware of the differences. Its also worth mentioning this module can kill you while you are working on the motor unless precautions are taken to avoid an accidental discharge of the ignition!

After 1977 Ford developed other ignition modules with white, brown or yellow wiring strain reliefs that have other features that are unneeded or even undesirable for retro-fitting breakerless ignition. They are designed to work with input from sensors, such as knock sensors, altitude sensors, MAP sensors, etc, and they are designed to control spark timing based on those inputs, to compensate for knock, altitude, engine load, etc. Or they are designed to work in conjunction with Ford's early "EEC" engine management systems. Some of these modules were called DuraSpark II, others DuraSpark III, and beginning in 1981 there was also the "universal" module.

Suggested Shopping List

(1) Rebuilt & recurved Duraspark distributor (sourced from a 1977 – 1982 351M, 400 or 460)

(2) Duraspark I module (reference a 1977 – 1979 California vehicle with a 302 V8 at the parts counter).

(3) Duraspark I coil (its a different coil than a Duraspark II coil)

(4) Painless Wiring #30812 Duraspark wiring harness

(5) Plug Wires: Motorcraft WR-3926R, Std Motor Products 6823, or Ford Racing Perf Parts 9mm plug wires

(6) Autolite AF32 (high compression) or AF42 plugs (or modern equivalents to those plugs)

Installation Notes:

1. When purchasing a module for your car, buy a new old stock module. The sealing material on the bottom of the module should be amber in color. Motorcraft #DY204, or Standard Motor Products #LX210. The NAPA modules were good too. I believe they were all sourced from the same manufacturer. They were very reliable. Eventually the manufacture of the modules was moved to Mexico, those would do in a pinch. The newer modules are Asian manufactured modules, I'd avoid those.

2. DuraSpark modules use a high voltage coil made specifically for DuraSpark ignition. Use the Ford DuraSpark coil or DuraSpark specific replacement such as Motorcraft #DG-316 or Standard Motor Products #FD-477 (0.70Ω primary winding resistance). Do not use a breaker point ignition coil.

3. DuraSpark coils are oil filled and must be mounted oriented vertically, with the top higher than the bottom. They must not be mounted lying horizontally.

4. Painless Wiring sells a wiring harness for DuraSpark II conversions. It can be employed for DuraSpark I conversions too with 4 modifications. It is available at Summit Racing under part number PRF-30812, or JEGS under part number 764-30812.

Those 4 modifications:

- The Duraspark II key tab must be removed from the 4 pin connector to use this harness with Duraspark I modules.

- The positions of the green wire and the orange wire must be reversed where they are spliced into the four pin connector's wiring.

- The ballast resistor included with the wiring harness is not used for a Duraspark I application.

- The alignment lug on the Duraspark I coil tower must be removed to allow the Duraspark II horse shoe style coil connector to slide on.

5. DuraSpark distributors for the 351C will be sourced from a 1977 through 1982 Ford vehicle equipped with a 351M, 400 or 460 cubic inch V8.

6. A ballast resistor suitable for DuraSpark II installations is available from NAPA Auto Parts, NAPA part number ICR23 (1.2 ohms).

7. The Duraspark distributor is not the best choice for sustained high rpm use even in perfect working condition, its propensity for spark scatter is infamous. For operation above 6000 RPM the distributor should be converted to centrifugal advance only, the vacuum advance plate should be locked out, the weight pins strengthened and the pick-up indexed with the rotor. Ford SVO once offered a distributor like this, part number M-12127-A301. Any Ford distributor should be expected to wear out within 50,000 miles. For the record the Moroso #72202 was the best mag pick-up distributor money could buy. It was a 351 Windsor distributor so the distributor drive gear required replacement to make it fit the 351C. But it had no vacuum advance. I'd recommend the MSD #8477 distributor for most applications.

8. The NOS US manufactured Duraspark modules are very reliable, good for over 100,000 miles and at least 10 years of operation. The Duraspark I ignition was one of the most sophisticated ignitions in its day. They lack one feature that is very important for performance driving, an engine speed limiter.

9. If a better ignition is desired, then my recommendation is to look beyond an ignition employing a distributor and consider a distributorless ignition such as the Ford EDIS-8 or Electromotive Engine Controls XDI system. Distributor ignition systems are as obsolete as the slide rule and typewriter.