quote:Originally posted by Edge: My Pantera runs fuel injection, 8 x 48mm throttle bodies.

Similar set up to Weber’s & a similar look. This is an old “Pantera Performance center” kit I found on Ebay.

I followed your build Tony and must compliment you on executing it very well. It’s very nicely done.

quote:I assume from the 1980’s.

Probably at least mid 90s or more recent. If it has TWM throttle bodies without the “Oldham” couplings, I believe Garry Polled implemented those about 10 years ago. He installed those between the barrels on his IDA throttle bodies because he said in instances where there was big temperature rise, the thermally enduced growth would cause binding due to the difference in linear thermal expansion between the steel shaft and aluminum TB. I have never had that issue (at least between barrels), and think this is more likely attributable to deformation of the intake manifold while mounting with the throttle bodies already mounted. This binding was a common problem on the older Hilborn, Enderle, Falconner, etc. and like units with a single shaft spanning all four barrels. Now, the connection between the two TB shafts on each bank on a set up such as yours is a totally different story.

quote:Velocity stacks I custom made, they are in two pieces where the top screws on to clamp in place a stainless mesh screen.

Those are very nicely done.

quote:Computer is a Motec with crank angle sensor, TPS & MAP sensors only. I rebuilt the throttle bodies & re-set the butterfly clearances. Runs really nice, easy to start & reliable. Combined with the 11:1 CHI 4V heads it made more responsive & snappier power.

That’s pretty Spartan as far as sensors go. I would think you would want to add several temp sensors for inlet air and coolant/engine temp. When you say MAP, are you trying to run a speed density scheme such as employed on a 4-Barrel by using a plenum plumbed to each barrel of your IR set up? Or just using it as atmospheric pressure correction? When you mention crank angle sensor, are you able to actively manage your ignition maps as well? As I mentioned in the earlier thread, the rest of the sensors such as O2, idle air valve, are really just for idle, warm up enrichment schemes, and leaning at cruise.

quote:The only issues I have had is balancing the throttle bodies to make sure they are all breathing the same amount at idle. Also, because of the high air flow of 8 x 48mm butterflies it requires a corresponding amount of fuel when snapping the throttle open from idle. So running rich at idle was causing the spark plugs to foul. Re-tuning the car at idle & leaning off the fuel didn’t work, it simply backfired. So now I have changed the Spark plugs from NGK BCP6ES to a hotter BCP5ES. Yet to try it & see if it has cured the plug fouling problem.

This is where you might benefit from some additional sensor input. Many of the aftermarket ECUs now have many algorithms and subroutines for cold start, off idle enrichment, warm up, idle control, that are very useful and user friendly. Not sure what Motec ECU you’re running. I’m not very familiar with them but in the past have known them for their high end racing stuff. Many people have had very good results plumbing a vacuum line from each runner to a plenum and using an IAC and closed loop O2 to regulate idle. Those doing so on plenums that also run their MAP sensor may find some problems caused by the IAC altering the MAP signal. Some isolate the two plenums. IT should be noted that these plenums can be sized and remotely mounted.

quote:The other issue is that each throttle body has its own return spring. And they certainly are required to get the butterflies to snap closed. But combine the tension of 4 x springs & it makes a very stiff throttle pedal.

I’d recommend you either put lighter springs in each TB or as you mention, consider different linkage. A spring on each TB is a good safety measure.

quote:So at some stage I’m going to have to look at a progressive throttle linkage to gain some more leverage & better throttle control.

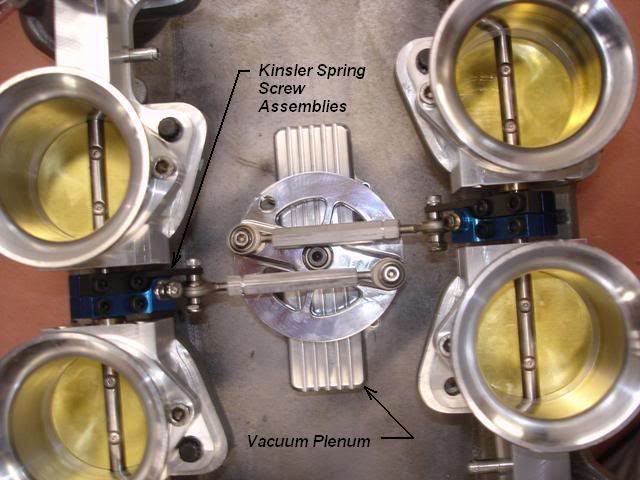

I’ve fiddled with a bunch of schemes and for the last ten years have always used the one pictured on the IR system below. I use this scheme on all my IR set ups from EFI, to Weber IDAs, and Inline Autolites. The throttle plates in each bank counter rotate to promote flow symmetry. The spring loaded balance bar linkage in the center between the TBs are very important. The ones pictured are a Kinsler product but the allows for axial growth and misalignment between TBs without binding. The cable actuated wheel is important feature of the linkage. In the initial position, the link arms are set close to center so that it takes much more rotation of the wheel in the early movement to produce the same change in angular position of the throttle plates. This gives good resolution with the accelerator pedal. It then get’s gained up progressively as you put your foot into it. The cable actuated wheel also has one subtle advantage over typical bell cranks schemes; you can calculate the diameter of the wheel for the exact amount of pedal/cable stroke for a given degree of rotation. The other thing is the mechanical advantage of the wheel on your linkage is always the same because the cable pulling force is always applied at a point the makes the applied lever arm half the wheel diameter. I mount the wheels in ball bearings and the linkage feels very nice. High quality linkage is very important for IR for performance, safety, and reliability to stay in tune.

These set ups will fit under a Pantera deck lid with 2" tall filter elements without notching the lid.

quote:In regards to Vacuum. I run an 8” dual diaphragm booster as my master cylinder is 1 1/8” bore, (4 piston rear calipers). I also run a vacuum bottle up front with an extra check valve. I tried supplying vacuum from one port & it was no where near enough. So tried 2 ports, still not enough. Then went to four ports & that was sufficient.

Mixing your comfort accessories with performance is like mixing business with pleasure. I’d recommend running a vacuum pump and separate plenum and circuit for your brake booster and call it a day.

Take care,

Kelly