Safety Wiring the ZF

I found that one of the parking brake cables had worn or dented the case considerably over the prior 39 years! Not sure if this is cause for concern. I expect that if the cable wears through the case here, it will leak - and I wouldn't want that to happen while blasting down the highway. That would be very expensive! I might have this welded up at a later date a as a precaution, but so far I haven't gotten to it in years.

I was pleased to see that all the original ring gear bolts were tight and secure.

I used these pieces of steel track to lock against the half-shaft bolts in the axle flanges to keep the ring gear from turning while I broke the bolts free.

If I recall correclty, I purchased ARP "Rover K Series Flywheel Bolts" to safety wire my ring gear. They came in a package of 8, so I had to purchase 2 additional bolts. I think Rocky on this board posted the info; search for his thread.

- Part#: 206-2803 (10 pcs total) for Rover "K" Series Flywheels

- M12AM.826-1F / M10 X 1.0 12PT FLYWHEEL BOLTS

- I also picked up some stainless steel safety wire

I think the following image is Rocky's. I forgot to take a pic of my package.

New ARP bolt compared to the original bolt (ARP bolt on left). Note that the ARP bolts are NOT pre-drilled for safety wire. I drilled them myself, and let me tell you... they are HARD! I broke 3 bits in the process.

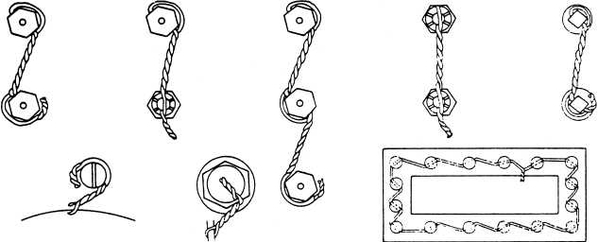

These are the proper techniques for safety wiring a bolt.

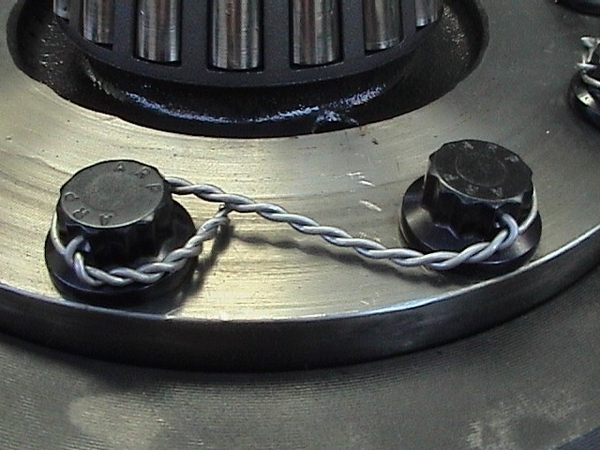

Following is a pic (not mine) of how to properly safety wire your ring gear bolts (on the left). I couldn't take a good pic of the safety wire on my own ring gear because I didn't remove it from the case; I merely rotated the ring gear so 2 bolts were at the top (bottom technically) and did it from the opening while the ring gear remained in the case.

I believe the above image may also be Rocky's.

Misadventure in the ZF

When using a ratcheting box wrench to rapidly tighten the ring gear bolts - do not stand on the opposite side of the case when tightening the bolts (towards you). Also, do not drink a beer with dinner before going back out to the garage to do this (probably the best advice).

These particular box wrenches are not reversible. Rather, they need to be removed and flipped over to reverse direction. I was careful that the 'on' side of the wrench was facing me and quickly 'tightened' the ring gear bolt. Unfortunately, since I was standing on the opposite side of the transaxle, I actually loosened the bolt that was previously finger-tight and backed it and the non-reversing ratcheting box wrench into the wall of the ZF case! No room to remove the wrench or bolt. I had hoped I could tighten the bolt back into the ring gear, but was able to get even a half turn of the bolt in the tightening direction because the case interferes with the wrench. Damn! What do do?!

And again, unable to pull the wrench and bolt out as it's too damn tight in there! After some frustration, a few choice words, and resisting the urge to break out a BFH to force the wrench and bolt out (it was close - only needed the case to deflect about 20 thou by my estimation - but decided that could prove to be a VERY expensive mistake), I broke out a Dremel tool with a small cutoff wheel and proceeded to cut the wrench in half to release the ratcheting/locking mechanism so I could spin the bolt back into the ring gear with my fingers and remove the box head of the wrench that had captured the head of the bolt. I then thoroughly flushed the case and I'm good to go, sans one 12mm ratcheting box wrench. FWIW - Craftsman no longer makes these wrenches - I imagine others have run into this situation and they have been deemed defective, or problematic at a minimum.

I made a tool to torque the bolts to spec - I'll have to take a picture of it and post later.

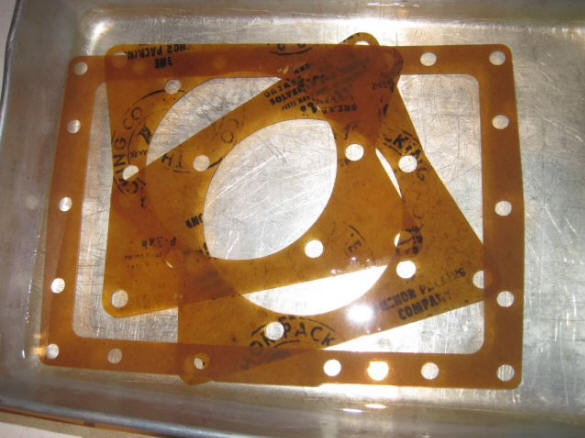

Soaking the ZF gaskets in water overnight (2 nights actually!) before use - tip from Hall Pantera.

If I were to do this again, I think I'd use Yamabond or some other gasket maker/sealer in a tube to seal the ZF as I do find gear oil weeping through the paper gaskets.