It sure looks like the pan Quella/PPC has sold forever but given the space constraints and the fact they need to interface with a C or W based engine, they’re all fairly similar. After the 351c my early engines were Windsor and aftermarket Windsor based engines. Current engine is Fontana which has the wider Cleveland pan rails.

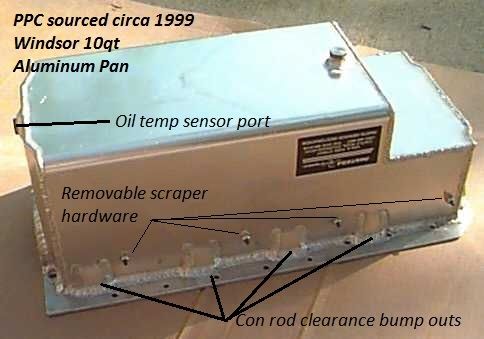

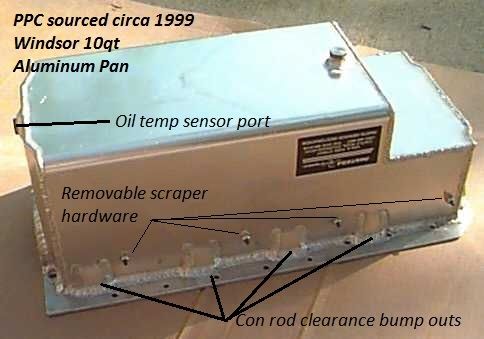

Below are some pictures of the two versions of the PPC sourced pans. The Windsor has small bump outs to clear the connecting rod hardware. They’re only needed on one side because of the different con-rod orientations heading to and leaving TDC. The Cleveland version does not have or typically need these features. The scraper was welded in on both pans but I removed it on my W pan and installed a removable scraper I could profile for changing stroker crank and rod combos. On the Cleveland pan, my Fontana engine is 3.9” stroke and with the wider C pan rails, it only needed a couple of tweaks to the scraper so it was left welded to the pan.

The Cleveland pan also has the oil pump bump out like yours whereas the Windsor does not. However, one of my early engines had girdled mains and the girdle would not clear the pan without making a small bump out in the same location (not installed at time of picture). This was just a small area that went a couple inches down from the pan rail. The Cleveland version oil pump bump outs run from top to bottom of the pan but wouldn’t need to….just the fabricator’s choice.

That section near the bump out get’s closer to the car’s frame rail, and if IIRC, on my Windsor pan the bump out I installed was very close to the shifting rod and needed share just a little bit of time with the business end of a ball peen hammer.

There are some subtle differences on your pan, such as the bump out was fabricated and added as a completely separate piece whereas the pans from Quella have integral bends and one weld. The oil temp sensor port is on the front face of the pans. The Windsor pan was sourced circa 1999 while the Cleveland pan was 2010. Dennis may have changed suppliers over the years but for quite a while had a fella that made a lot of cup car pans and operated out of a small shop to making them…..nice work.

On the pick-up height distance from pan, the general rule of thumb that is always bantered around is the cylindrical area of the opening comparable to the circular area of the pick-up but I always thought that was fairly conservative and would say no more than that and could be a bit less when you look at the size plumbing it feeds.

Aluminum 10 quart pans weighe about 10 lbs. Besides the extra volume, the aluminum pan will save you 5+ lbs and run 10-20F cooler depending on conditions. I’d suggest you fix the pickup, check interface dimensions, make sure the trap doors in the pick-up trap swing freely and it clears your dip stick (which will need to be adjusted for the 10qt pan), consider installing a scraper, and run it……why not?

Best,

K