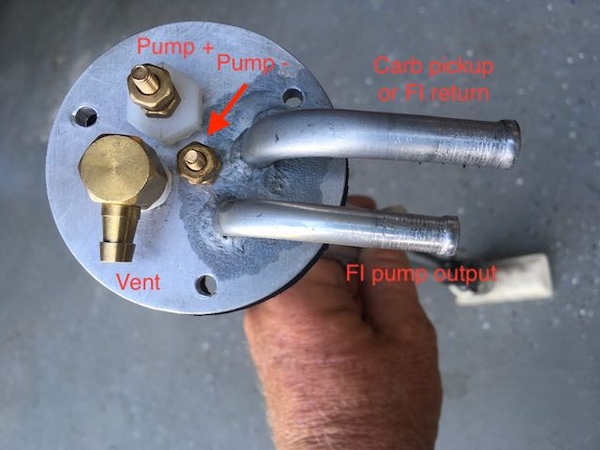

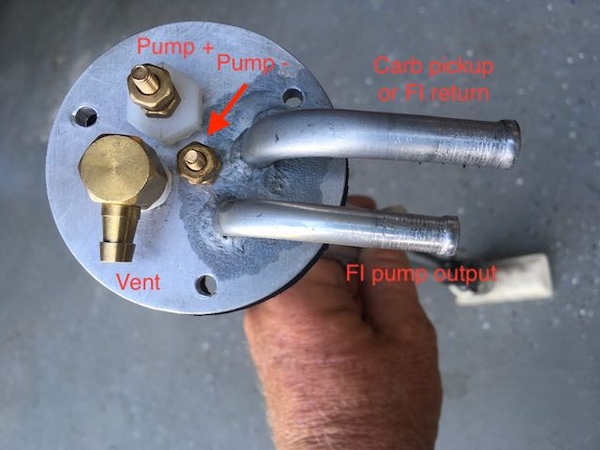

Here is the business end of the unit, along with a photo of the entire assembly. The flange is 1/4" thick aluminum. The carb pick up / FI return line is 3/8" aluminum tube. It also serves as the main mechanical support for the pump itself. The FI pump output line is 5/16 aluminum tube, the same as the output nipple on the pump itself.

These two tubes are brazed / soldered to the flange with that zinc brazing technique. It is genuinely useful for some applications, but harder to do than the advertisements make it seem.

You can see that both tubes are bent slightly about 4" below the flange; this compensates for the angle of the mounting surface, and makes them vertical inside the tank.

The 3/8" tube is also flattened slightly where the pump is attached to it. This gives a better support surface for the pump body so it doesn't move around. It also reduces the overall diameter of the assembly there, as it just barely fits in the stock opening of the tank. The pump is held in place with safety wire for the same reason, as there is not enough room for hose clamps. The very end of the 3/8" tube is bent out slightly, so it doesn't interfere with the pick up filter of the pump.

The two aluminum tubes had to be brazed to the flange first due to the heat involved. I had to shorten the nipple of the vent piece about 1/4" so it could be screwed in.