Hi Steve,

My $0.02...

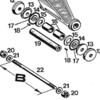

Zerk fittings are easily done. I don't believe there is value in purchasing a "kit". I don't believe the rotational orientation makes any difference. I'd pick a location that will make greasing them as easy as possible for your particular set up (wheels ..etc). I'm with Kirk, I file a couple "very" small grooves equally spaced around the bushing to permit the grease to easily migrate the full length of the bushing. The suspension movement will then distribute the grease around the bushing.

I would choose the zirk in the upright over drilling the shaft simply due to the strength loss to the shaft of making it hollow, with holes then also drilled out radially to distribute the grease. I feel this makes it way too weak. Plus...the upright modification is much easier to actually do.

Either way you slice it...I'd do it. If these seize up and break...it's ugly.

Nice illustration JFB..!