Hello All

Since I've received my engine stand

I'm ready to operate !

I bought #2902 in 2012 fitted with an upgraded stock 351 CI engine, The cam was way to agressive, that it couldn't work !

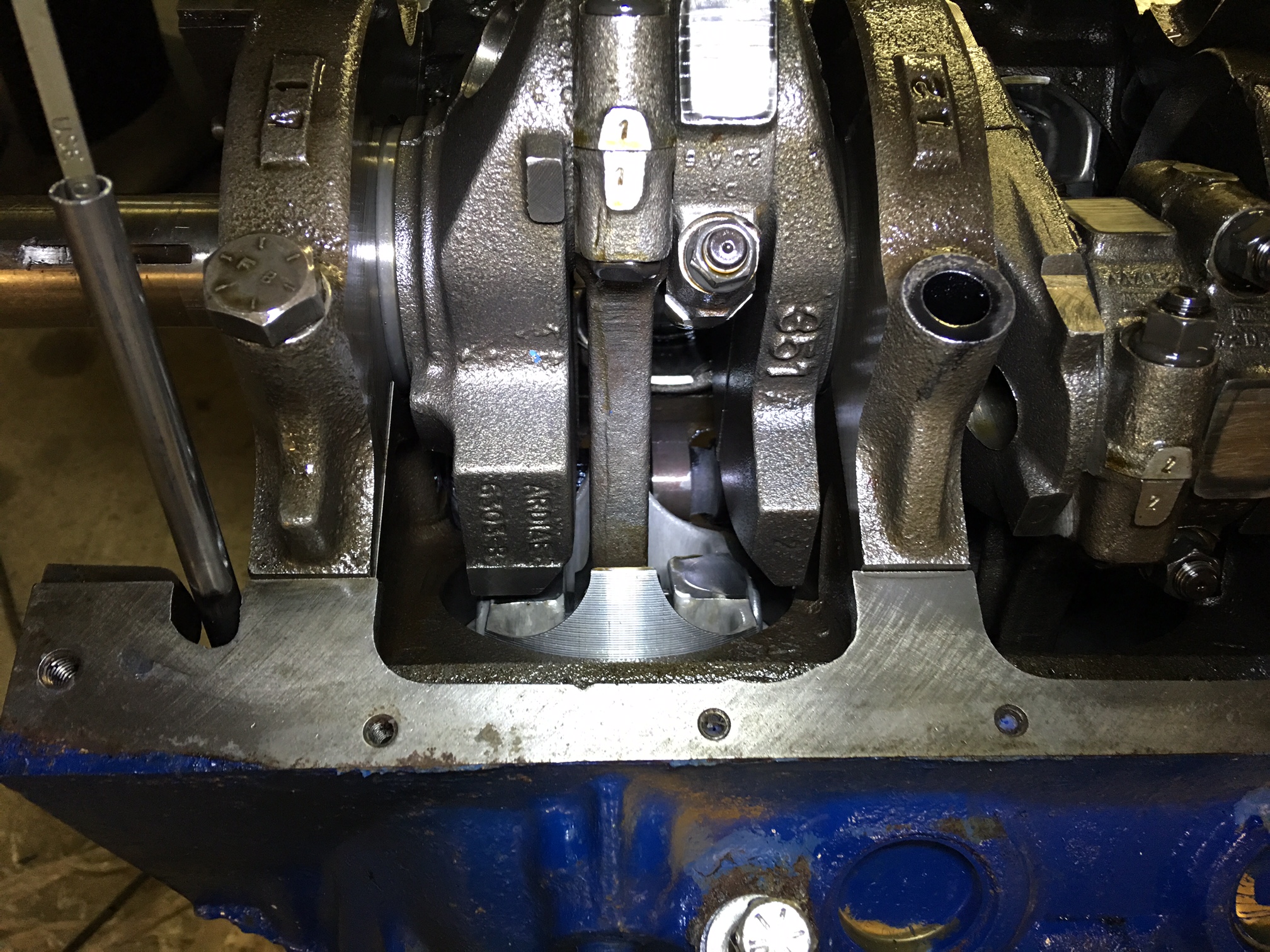

Here's what I have now, the car wil be a gr4 replica car ...

-351ci block, with a custom camshaft from Brent Lykins (target 3500-6500 power band)

-Quickfuel race carb

-Dominator intake,

-180° headers,

-custom dizzy with MSD capacitor ignition,

-10/1 CR, crane (gold colour plated)rocker arms,

-Pioneer race balancer (adviced on it)...

-Aviaid baffled oil pan.

-alu high flow water pump

-lightweight hi-torque starter

I will not use dry sump oiling,

I'm listening and welcoming all advices

Pictures will follow during engine build.

thanks !

Philippe

Original Post