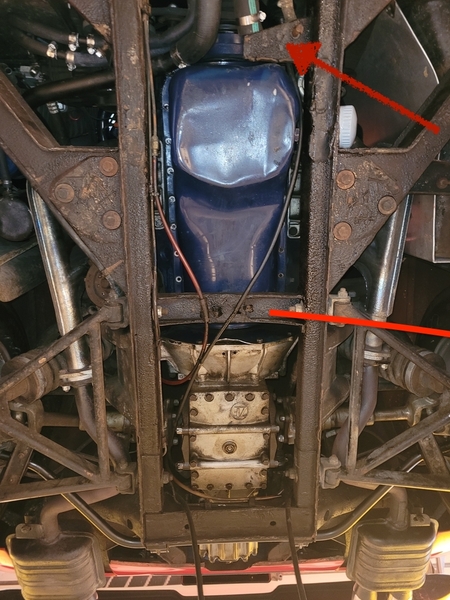

Once all the bolts are out, the pan drops down 8" or so, then moves forward 6-8" to clear the oil pulp pickup screen from around the internal pan baffle. Once the pan is out, you can pound the distorted bottom back flat- a new pan is usually not required. The oil pump pickup should be 3/8"- 1/2" ABOVE the pan bottom; yours is likely touching- or bent from a previous removal attempt. And that will cause oiling problems at higher rpms. Cars made after Ford left in '74 have a removable crossmember and a removable e-brake bracket. DeTomaso used to sell those in Europe as upgrade parts, but of course they are no longer in business. A few specialty shops may stock these parts either as billet or modified-stock.

As was said, it's better to pull the engine because getting a new pan gasket to seal in the corners near the front & rear pan seals is picky enough working upside down that you'll wish you'd pulled everything. A rotatable Harbor Freight engine stand makes it easier. It's also a h...uvalot simpler to cut the crossmember out neatly with the engine out. There are welded flaps above, below and on both sides, and the front lower rear a-arm fasteners go thru the crossmember flaps. A Sidewinder and a coarse disc or a reciprocating saw are your best friends in removing all this debris; just don't damage the main frame rai!s while cutting! You'll need to weld back steel pieces to your crossmember ends so its now bolt-in-removable, or the chassis stiffness and handling will be severely affected. Ford did us no favors here!

Once the e-brake bracket is cut off, weld on a piece of angle-iron at the cut for a screw on bracket so the OEM bracket is then removable. There should be no reason to adjust the e-brake afterwards. As you can see, on uncut cars, all this is a fairly major job. Mike Daily's web site 'www.PanteraPlace.com' probably has the work illustrated.

![20211020_165427[1] 20211020_165427[1]](https://pantera.infopop.cc/fileSendAction/fcType/0/fcOid/20327796565077262/filePointer/20327796566119824/fodoid/20327796566119820/imageType/MEDIUM/inlineImage/true/20211020_165427%255B1%255D.jpg)

![20211020_165427[1] 20211020_165427[1]](https://pantera.infopop.cc/fileSendAction/fcType/0/fcOid/20327796565077262/filePointer/20327796566119824/fodoid/20327796566119820/imageType/SQUARE_THUMBNAIL/inlineImage/true/20211020_165427%5B1%5D.jpg)