You will probably have to remove the valve covers; good idea anyway to get a look at the springs, etc.

Stuff the ports with paper towels to keep debris from dropping in. Likewise cover the galley(shop rags work well)to keep trash from falling into oil return holes, etc.

You can leave the dizzy in place.

Clean all surfaces until clean. Razor blades, scotchbrite, solvent and elbow grease.

Do a dry fit when things are cleaned. Check gaps for uniformity. Note end rail gaps - you'll be filling this with silicone. Read on.

You may need an aftermarket carb-linkage adapter. Nothing you couldn't fab on your own. Pretty sure the vendors sell one ready-made.

Check for full throttle travel before putting the air cleaner assembly back on.

New air cleaner in the plan? Skip the fancy, oil type open-top foam cover; they do not agree well with flaming back fires.

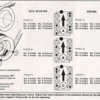

Personally, I do not like the 'turkey-tray' OEM-style intake gasket. Others swear by them.

Both will work just fine, if installed correctly. Have you purchased gaskets yet?

Felpro 1228, their Printoseal line with a blue sealant circling the ports.

Permatex "Sensor-save Ultra Grey", item # 82194.

End-rail gaskets may be cork or rubber; whatever they are, throw them away. Use about a 1/4" bead of the Permatex RTV silicone applied to the block only. Also run the bead about 1/4" up the head surface. I take a sharp center punch and dimple the block end rails and the intake end rails; this gives the silicone some places to get a "bite" to hold better.

Observe proper torque pattern and settings. I like a three step process.

Give the silicone some time to set-up before engine start. I like overnight.

Go slow, keep things clean, think clearly. This is not a big-hassle job and can be successfully accomplished by most of us.

Get on the forum and hit us up for advice if you get in a jam before getting in a bigger jam.

Larry