Panteras had either a type 2 valve with a short piece of flat stock protruding thru a contoured slot that acts as a cam to open & close the valve. Type 1 valves had a round bent rod sticking out to form the lever that shuts off water flow. Both worked equally bad when new. Inside both, there is a tiny o-ring that acts as a seal. A solid wire Bowden cable protrudes thru the attachment on whatever lever you have, and a sheet metal support bracket for the cable is usually present. Adjustment is by how much wire sticks thru the clamping screw. About all that can go wrong is, the o-ring leaks. Oh, and the fact that the valve lever and the dash adjustment lever are mismatched such that the valve can be set to fully shut off water flow but not fully turn it on. This degrades both heater and defroster action.

Alternatively, you can set it to fully turn on but NOT fully shut off. So in this case some hot water will always be flowing, which adds a second load the AC system must overcome before you get cool air. The heater core and the AC evaporator core are bracketed firmly against each other so they share airflow thru the heater box under the dash.

In addition, the short heater hoses connecting the valve to the engine have been known to rupture at high rpms, scalding your (or your passenger's) ankles with boiling water and fogging up the windshield- usually at high speed. Crashes and injuries have resulted.

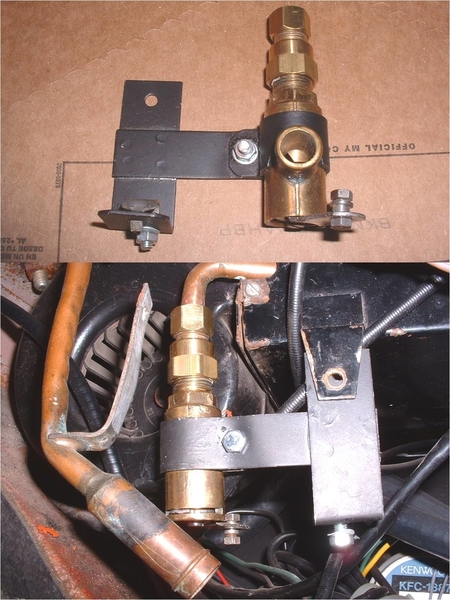

That's why Panteras that see some track events are required by Tech Inspection to have secondary positive shut off valves (hardware store 1/4-turn ball valves are popular) visible in both heater lines between the engine & valve. These are excellent safety devices for road cars, too. Much effort has been spent on upgrading this valve, often without success. Many simply remove it or bypass it- which also has its drawbacks. The archives are full of such articles.