This is my first carbureted V8 and my first Holley carburetor.

I have some experience on four cylinders powered by two Weber twin barrels (DCOE and IDF) but it looks quite different to me.

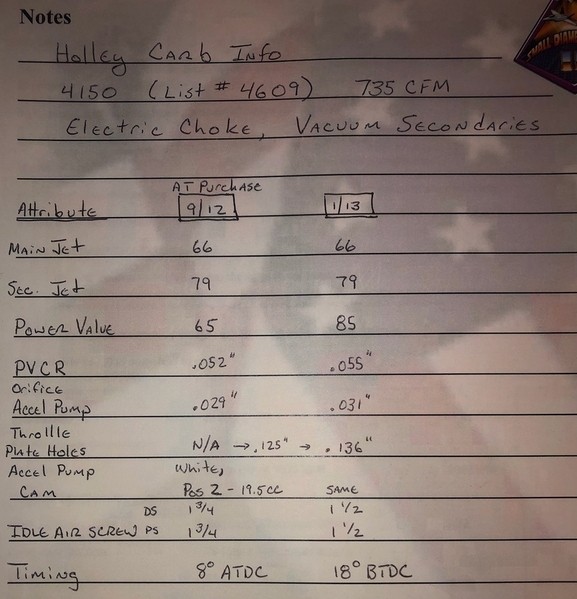

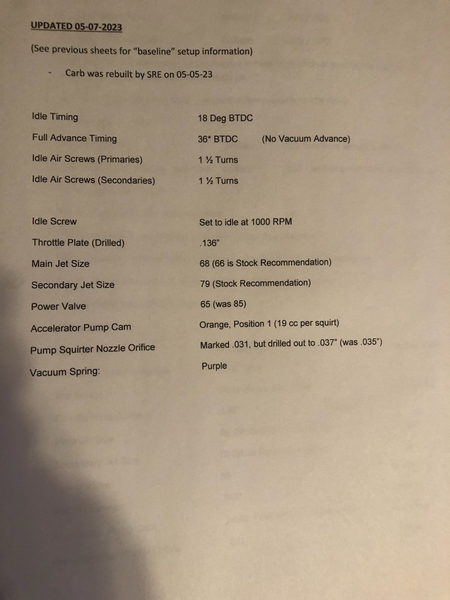

So I have a new engine, stroked at 382 CI with a static compression ratio of 10.6/1 and a cam that has an intake opening time of 285° and 231° at 0.05''. My carburetor is a 750 CFM 4150 with annular boosters (reference 0-9379) and electric choke mounted with a BlueThunder dual plane manifold.

I'm having trouble getting the engine to start and can only do it with the idle screw almost fully open and there's a lot of backfiring. (luckily I have mechanical secondary). When the engine has finally started and it has warmed up a bit, I manage to reduce the engine speed to +/- 1800 rpm, below it stalls.

So I could not adjust the ignition correctly, which is around 18° at 1800 rpm.

With the idle richness screws open 1.5 turns the smoke is very black and I have to close them almost completely so that the smoke is almost normal.

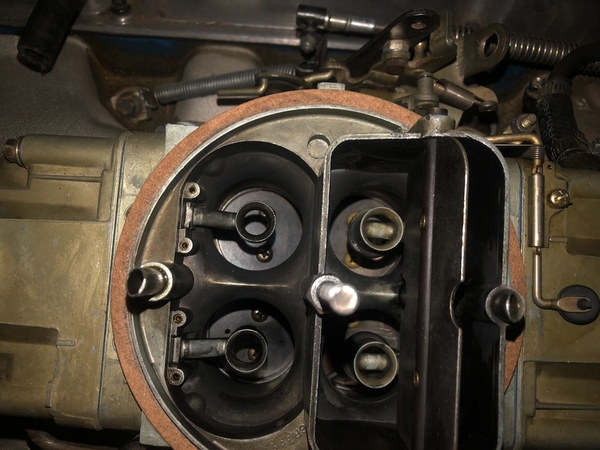

I have David Vizard's book "How to super tune and modify Holley Carburetors" and it is my understanding that these symptoms indicate a lack of air which often occurs with a cam over 280°. So I opened the secondaries to the maximum with their idle screw, it only slightly improved the situation.

In this book it says that to solve this problem you have to drill small holes (between 1/16 and 1/8 '') in the butterflies, have any of you already done this? What was the result?

Do you think there could be other causes.

Thanks for your help.