Hello Art, welcome aboard.

I would like to add three concepts to the stroker discussion:

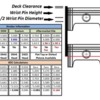

First - most people aren't aware a factory 351C pulls its wrist pin 1/8" out of the bore at BDC. Notice in the picture below that the 408 stroker only pulls the wrist pin out of the cylinder 0.038" more than the OEM 351C dimensions. BUT the 351C has a 1.65:1 rod length to stroke ratio, whereas the 408 stroker has a dismal 1.5:1 ratio. 4V & Proud's picture provides proof as to how important the rod length to stroke ratio is. That is one of the parameters the aftermarket is juggling with their stroker kits. A short rod length to stroke ratio not only places undue wear on the piston skirts, it also places excessive thrust on the thin cylinder walls.

Although everyone understands how deck height impacts a stroker project, the height of the cylinders is seldom discussed. The 351C cylinders are about 5.5" in height. This is the second issue. To sum up my perspective on the subject, the wrist pin should never be pulled-out from the cylinders. BUT if it must be pulled out from the cylinders, the amount it is pulled-out should decrease as the rod length to stroke ratio decreases. In the case of the 408 stroker the opposite occurs, the rod length to stroke ratio decreases yet the amount the wrist pin is pulled out from the cylinder increases.

The third issue is the wrist pin intersecting the oil ring groove. In the past it caused oil burning, today there are solutions for the resultant oil burning, it can be lessened by second ring designs or by adding a special dimpled rail support behind the three-piece oil ring. However, from my perspective that is a Band-Aid solution for poor engineering, I would never recommend assembling an engine in which this happens but I understand perfectly the different perspective drag racers have (remember this is a sports car forum

).

10 years ago Scat's piston for their 3.85 crank did not intersect the oil ring groove, but the material between the wrist pin bore and the oil ring groove was paper thin. That combination was designed for a deck height of 9.200" , and it had a wrist pin height of 1.275". I don't know if the dimensions of Scat's 3.85 kit have changed, but the wrist pins of other 3.85 stroker kits do intersect the oil ring groove. Its safe to say that in order to avoid the intersection of the wrist pin bore with the oil ring groove requires a wrist pin height of 1.300" (of course this only applies to engines with Cleveland heads).

You haven't mentioned what type of vehicle the engine is going into, the application (racing, cruising, etc) how often the car shall be driven, or what your expectations are in regards to the engine's longevity. IF you have expectations for longevity, if you plan to drive the car frequently, or if the car shall be used in road racing my advice would be to not exceed anything more than 3.75" stroke and a 6" Chevy connecting rod.