Tried to fire it up and it would start up for a few seconds and run but it sounded weak and like it wasn't really firing up completely and wouldn't go above 1000 rpm and there was one pop out the exhaust. Killed it and tried changing the timing some and still wouldn't fire up right. Pulled the valve covers and turned it over and all the rockers looked to be moving well. We hooked the timing light up to each wire and all were getting spark. Pulled the fuel line off the connector before the carb (Holley) and there was no fuel. There was fuel in the bowl but was about dry when we were digging in to what could be the problem. So I know I have a fuel issue, although I feel like there might be more than just that because it didn't fire up and roar even when we first started it (and fuel had been poured into the carb).

For the fuel issue, my fuel pump was off the side of the motor for a good 5 weeks. Is that long enough to dry out the diaphragm and warrant it being replaced. I am in Mississippi so it's been super hot but it's always pretty humid out. I'm going to try and put some vaccuum on the line and see if I can pull fuel through it. If the fuel pump was pulled and the line between it and the carb replaced and a new filter installed. How long does it take to prime it? Any way to prime it without just sitting there cranking the motor, with a brand new cam I don't want to just sit there and turn the motor over for a long period of time to prime the system? The fuel system was working just fine before everything was pulled 5 weeks ago for the cam swap. Is it possible to install the fuel pump wrong? I felt tension on it when installing it and tightening it down like it was against the fuel cam.

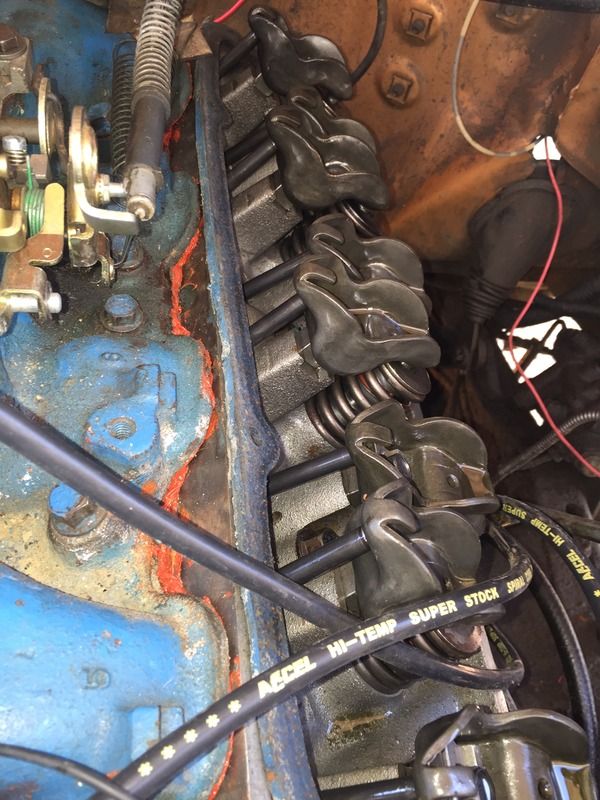

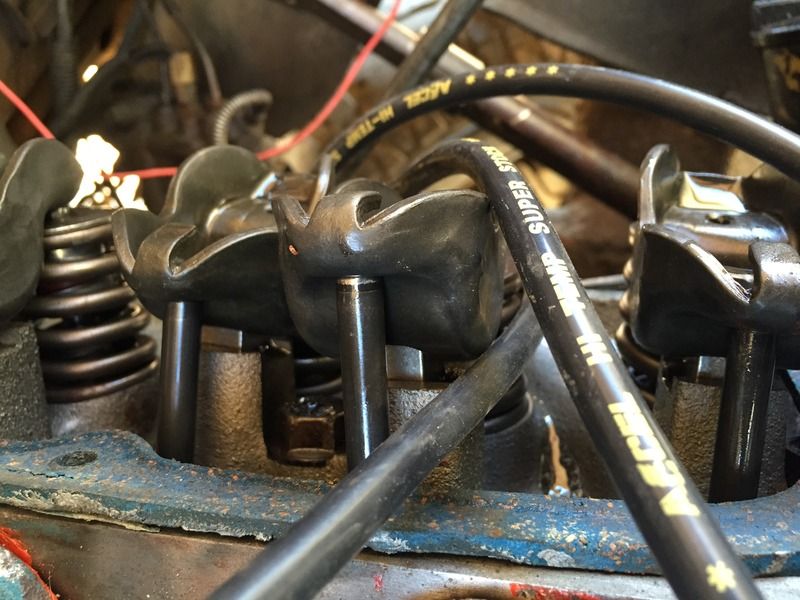

Now on to it not firing up and roaring like it should even when I had poured fuel in the bowl. Any ideas where to start on this? I plan on pulling all the plugs and checking them to see what they look like, I guess I should probably check compression on all the cylinders as well while I am at it. The plugs were installed when I was diagnosing what my problem was before I found out the cam had wiped a lobe. The truck would fire up and run pretty strong before cam swap, it would just pop like a fool when you gassed it and would bog. Could there be some problem with my MSD ignition? It's all brand new. I know it's at least getting spark to all cylinders since checked with the timing light and the fact that it did run weakly for a few seconds. Could the coil not be making enough power? I know it's unlikely but I'm just kinda stumped here. What about timing or the distributor not being right? When installing the timing chain set the metal woodruff keys on each gear were directly facing each other when it was put on so should have been at TDC right? Nothing was touched on the crank during installation of the balancer and all so it still should have been right. Then we dropped the distributor in with the rotor pointing at Number one on the Cap and adjusted it to 10*. Tried it with the timing at like 12 and 16 or so as well and still nothing. We checked firing order several times. Did not see any mention of the new Comp cam having a different firing order anywhere.

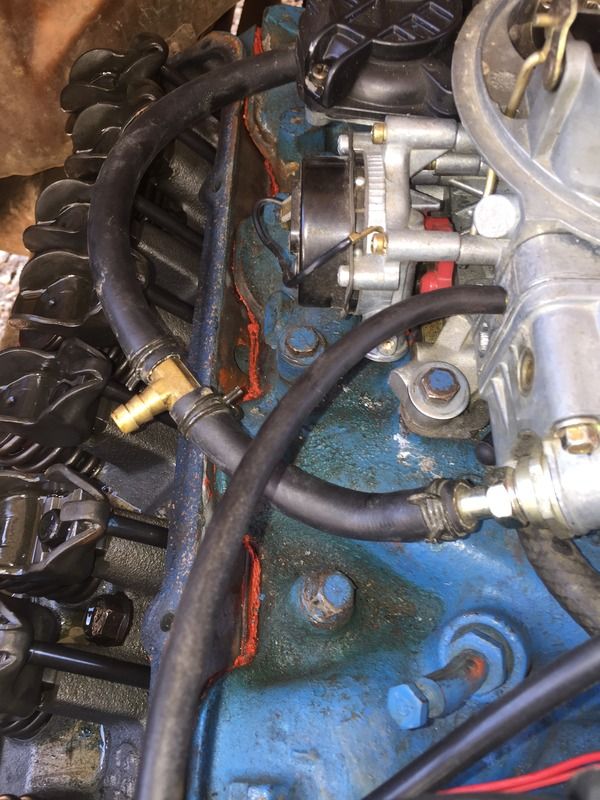

Also, the intake seals I used and the manifold I have definitely didn't match. I have the small ports on my heads, and thus used the small\ Felpro intake seals (have both actually). They fit nicely around the ports on the head. The ports on the manifold are much bigger. I have no clue what it is off of but was on the truck when I got it. Looks like it was a factory 4V intake manifold. It has the funky little line/ridge in the top around the holes where the carb sits (saw it might be some strange variant from 73). It had a metal valley pan gasket on it when I got it and was RTV'd around the edges. There are two holes in the heads not covered up by the intake manifold. When I got the truck these were covered in RTV. I stuck a probe down there and they don't appear to go anywhere. I left them open for now but was going to silicon them just to keep crud from building up in there. The thought has crossed my mind that maybe there is some kind of leak going on here which might be keeping my motor from firing up strong/right combined with the lack of fuel making it to the carb.

I am by NO MEANS a mechanic or mechanical expert, I'm a very mechanically inclined motorcycle builder who is very competent in auto stuff like wiring, suspension, brakes, customization, etc. However old engines/timing/auto carbs are by far my weak point.. I know a fair amount but My buddy who is a mechanic and has his own shop was helping me through all this and did the timing setting, timing chain installation, and distributor install but I am one who never trusts anyone, ever. So if something I described doesn't sound right please let me know.

Here's a few pics even though they might not help. Notes for the pics: Gaskets are the large ones I did not use, the ones I used look identical but with smaller ports. I also noticed a little silver spot on top of one of the pushrods, although it could have been from when there was a stuck lifter from the wiped cam lobe. They all looked clean and straight and had very low miles on them so were reused:

Any helps would be greatly appreciated. I've hit every minor bump in the road possible with getting this truck to run right and after getting it all finally together again and running into all this I'm about to the point where I just want to pour gas all over the entire truck and watch her burn lol.

Thanks,

Spencer