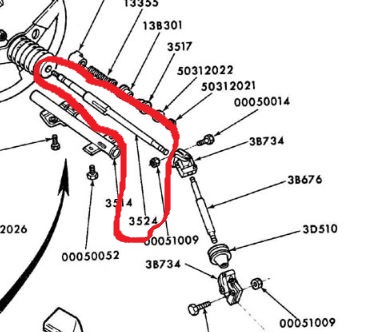

There is a slip-joint in the upper steering ass'y- part of a 'safety factor' built into an impact-collapsible steering column. The outer part has flat sides that originally used a thin shim-strip of slippery polyethylene (or something similar). These strips apparently evaporated soon after delivery, leaving the slip-joint a bit loose. There is no way to grease the movable parts or add a home-made shim-strip except by hand during total disassembly.

Owners that are bothered by rattles or slight play in their steering caused by the collapsible section, either squeeze the flat sides of the outer sleeve together with Vice-grip pliers or a big c-clamp to remove some/most of the slop in the slip-joint. Or they drill a 1/16" hole thru the inner AND outer parts of the ass'y and insert a small OD cotter pin- not a screw. This locks the two parts together and eliminates that rattle. In a serious crash, the soft steel cotter pin should shear, thus maybe restoring a rudimentary 'safety' factor against being speared by the steering shaft. Threaded fasteners will require too large a hole, weakening the steering shaft Other less patient owners tack-weld or braze the slip-joint together and eliminate it's safety factor.

Note- if you do this, it is YOUR responsibility. Don't come to me if you wind up being punctured by a part of your car that YOU modified! (Std disclaimer)

Since all this is done in place under the dash while upside-down, it's only for the excessively limber. When slipping a cotter pin thru the drilled hole, try to arrange it so the sharp ends don't snag your pant leg (or bare skin) in turns.