What are the latest trends in updating the rear wheel bearings? I wonder if "ceramic" bearings are available to match the original bearings? Have any of you come up with your own modified versions which you find to be better?

Replies sorted oldest to newest

Are you investigating bearings because you have diagnosed a problem or are you just seeking a project?

how many miles are on your car and how many miles do you put on your car each year?

Many rear axle problems are a result of excessive wear on the stub axle’s. The miles on your car and/or known upgrades or maintenance would provide a clue if the bearings have in fact reached the end of their life span

The stock OEM bearings are readily available and the process does require some skills and a hydraulic press, but it is not a difficult or precision task.

I know of nothing inherently inadequate with the stock bearings, certainly no more so than in any other classic automobile.

Sometimes original is good enough.

Larry

I am in the process of totally restoring my Pantera. While it is apart, I want to replace the rear axle bearings with the best parts available now. It's a lot easier to use the best parts and seek advice now instead of coming back later and having to go through the process again. I have had to replace "bad" bearings in a Pantera before.

Thanks for your reply.

It used to be popular to replace the sealed ball bearings with tapered roller bearings but it seems that isn't as popular as it once was. The tried and true update from OEM is to replace the smaller inner bearing with a double row bearing of the same OD. The only modification required is to shorten the spacer between the bearings by an amount equal to the extra width of the double row bearing. In fact, I believe Wilkinson sells the appropriate short spacer. The factory began using a double row inner bearing some time after their separation from Ford, so you could say this modification was "factory approved".

Reply By davidnunn: Rear wheel bearings

| == To reply by email, write above this line. == |

|

| |

| Hello, old7: We're sending you this notification because you are either following the forum, the content, or the author listed below. New Reply To Topic

| Subject: Rear wheel bearings Reply By: davidnunn In: Technical Information Forums / Gearbox - Clutch - Half Shafts - Rear Axles | |

It used to be popular to replace the sealed ball bearings with tapered roller bearings but it seems that isn't as popular as it once was. The tried and true update from OEM is to replace the smaller inner bearing with a double row bearing of the same OD. The only modification required is to shorten the spacer between the bearings by an amount equal to the extra width of the double row bearing. In fact, I believe Wilkinson sells the appropriate short spacer. The factory began using a double row inner bearing some time after their separation from Ford, so you could say this modification was "factory approved".

View This Reply The De Tomaso Forums https://pantera.infopop.cc To adjust your email notifications for this site, please update your notification settings. To suspend ALL email notifications from this site, click here. |

|

I don't have the part # handy but I'm sure it's here in the forums.

It is more advisable to replace the outer bearing with a double row ball bearing because it is it who is the most loaded, but that forces to deepen its housing in the Hub.

Reply By davidnunn: Rear wheel bearings

| == To reply by email, write above this line. == |

|

| |

| Hello, old7: We're sending you this notification because you are either following the forum, the content, or the author listed below. New Reply To Topic

| Subject: Rear wheel bearings Reply By: davidnunn In: Technical Information Forums / Gearbox - Clutch - Half Shafts - Rear Axles | |

I don't have the part # handy but I'm sure it's here in the forums.

View This Reply The De Tomaso Forums https://pantera.infopop.cc To adjust your email notifications for this site, please update your notification settings. To suspend ALL email notifications from this site, click here. |

|

Thanks for all of the advice and pictures. On Tuesday, June 2, 2020, 07:11:04 AM EDT, The De Tomaso Forums <alerts@crowdstack.com> wrote:

Reply By rene4406: Rear wheel bearings

| == To reply by email, write above this line. == |

|

| |

| Hello, old7: We're sending you this notification because you are either following the forum, the content, or the author listed below. New Reply To Topic

| Subject: Rear wheel bearings Reply By: rene4406 In: Technical Information Forums / Gearbox - Clutch - Half Shafts - Rear Axles | R |

It is more advisable to replace the outer bearing with a double row ball bearing because it is it who is the most loaded, but that forces to deepen its housing in the Hub.

https://pantera.infopop.cc/top...909#1598208419990909

View This Reply The De Tomaso Forums https://pantera.infopop.cc To adjust your email notifications for this site, please update your notification settings. To suspend ALL email notifications from this site, click here. |

|

A few thoughts on my 40 yrs of continuous ownership of #4366:

I've fixed a number of Panteras with 'bad wheel bearings'. In most cases, the bearings were perfect but the OEM stub axle was worn. And by 'wear', I mean maybe 0.001" of metal missing or pounded into a tiny ridge around where the bearing race runs. To check these dimensions, one needs a five-place 1 to 1-1/2" micrometer or you're just guessing. What happened at the factory that originally made the axles was, some of the hollow stock axles were machined slightly undersized for a proper press fit into the wheel bearings. OEM bearings by SKF or anyone else requires a 0.0003"-0.0008" interference fit. And yes- all those zeros are important. A 6 inch calipers or Harbor Freight mic' won't tell you this.

* Many of the OEM axles were made with NO press-fit interference as mentioned. Compounding this problem, bearing-race steel is super-hard while stock stub axles were made of mild steel. This combination only works IF the press-fit dimension is correct. If the fit is loose for any reason, guess which one suffers? Right- the softest one.

* Nowadays, repro axles are made of 300-M steel and are solid, not hollow: better steel and a 20% stronger design. I no longer weld-repair stock axles- the repo's are simply better all around. Don't waste your money on hollow OEM axles with any sort of repair.And the nuts are supposed to be one-use-only.

* Big sticky tires: If stock axles don't wear from inadequate press-fit, they break under even stock engine torque with oversized modern tires and sticky rubber compounds. Real racers know that perfect, properly assembled stock rear axles and race tires were mostly good for about 4 hrs of intensive racing before the axle broke at the shaft-to-wheel flange. A dozen laps of club-level open-track is not 'intensive racing'.

* To check the ball-bearing-vs-tapered-rollers thing, over 20 years ago I converted ONE side of our Pantera to tapered rollers (my own design) and the other with stock ball bearings- with correct press fit. They've both been on our car for coming up on 50,000 miles- none of them very easy. No problems from either side so far, so no advantage either way. Theoretically, ball bearings should run cooler but I've seen no measurable difference on the street.

* Tightness of the axle spanner nut: the SAE says that a fine-thread steel shaft & nut of 1-1/2" OD will shear at around 1100 ft-lbs. At only 400-ft-lbs of torque as used on most Panteras, the inner bearing spacer, again of mild steel, will indent against the much harder bearing races and get shorter over time, running 400-500 bhp through the assembly. Some shops and owners face the spacer smooth so it looks nice. Re-tightening the nut with a now slightly shorter spacer forces the nut to thread down the axle a little further. At some point, the axle runs out of threads so the nut is really tight but the sandwiched assembly is a bit loose. Bingo- another 'bad wheel bearing'.

"It is more advisable to replace the outer bearing with a double row ball bearing because it is it who is the most loaded, but that forces to deepen its housing in the Hub."

Just to clarify; in order to do this, you have to modify the upright, by machining the outer bearing recess deeper by a significant amount.

Yes that's it:

Hi Rene -

How do you fixture and perform this machining operation?

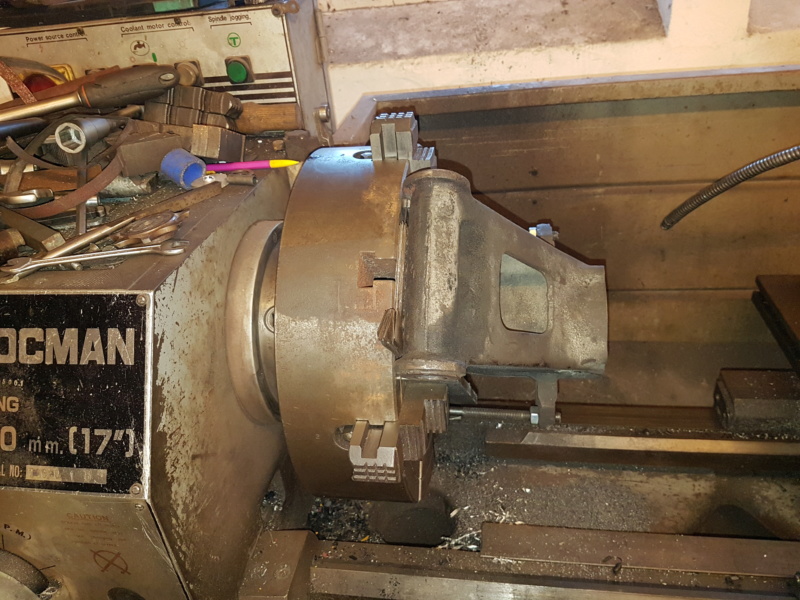

I guess it could be done on a (big) lathe with a boring bar, but mounting the upright to the headstock would be a challenge.

Is there a boring tool that could be used on a mill?

Just curious, from a machining perspective.

Thanks -

Rocky

The best would be a milling machine with a boring head but I didn't have one yet (I only bought one last week) and I used a lathe with a 4-jaw plate

And here is a link to a video:

Since I reassembled the hubs and everything is fine.

Thanks for replying. On Wednesday, June 3, 2020, 12:41:04 AM EDT, The De Tomaso Forums <alerts@crowdstack.com> wrote:

Reply By bosswrench: Rear wheel bearings

| == To reply by email, write above this line. == |

|

| |

| Hello, old7: We're sending you this notification because you are either following the forum, the content, or the author listed below. New Reply To Topic

| Subject: Rear wheel bearings Reply By: bosswrench In: Technical Information Forums / Gearbox - Clutch - Half Shafts - Rear Axles | |

A few thoughts on my 40 yrs of continuous ownership of #4366:

I've fixed a number of Panteras with 'bad wheel bearings'. In most cases, the bearings were perfect but the OEM stub axle was worn. And by 'wear', I mean maybe 0.001" of metal missing or pounded into a tiny ridge around where the bearing race runs. To check these dimensions, one needs a five-place 1 to 1-1/2" micrometer or you're just guessing. What happened at the factory that originally made the axles was, some of the hollow stock axles were machined slightly undersized for a proper press fit into the wheel bearings. OEM bearings by SKF or anyone else requires a 0.0003"-0.0008" interference fit. And yes- all those zeros are important. A 6 inch calipers or Harbor Freight mic' won't tell you this.

* Many of the OEM axles were made with NO press-fit interference as mentioned. Compounding this problem, bearing-race steel is super-hard while stock stub axles were made of mild steel. This combination only works IF the press-fit dimension is correct. If the fit is loose for any reason, guess which one suffers? Right- the softest one.

* Nowadays, repro axles are made of 300-M steel and are solid, not hollow: better steel and a 20% stronger design. I no longer weld-repair stock axles- the repo's are simply better all around. Don't waste your money on hollow OEM axles with any sort of repair.And the nuts are supposed to be one-use-only.

* Big sticky tires: If stock axles don't wear from inadequate press-fit, they break under even stock engine torque with oversized modern tires and sticky rubber compounds. Real racers know that perfect, properly assembled stock rear axles and race tires were mostly good for about 4 hrs of intensive racing before the axle broke at the shaft-to-wheel flange. A dozen laps of club-level open-track is not 'intensive racing'.

* To check the ball-bearing-vs-tapered-rollers thing, over 20 years ago I converted ONE side of our Pantera to tapered rollers (my own design) and the other with stock ball bearings- with correct press fit. They've both been on our car for coming up on 50,000 miles- none of them very easy. No problems from either side so far, so no advantage either way. Theoretically, ball bearings should run cooler but I've seen no measurable difference on the street.

* Tightness of the axle spanner nut: the SAE says that a fine-thread steel shaft & nut of 1-1/2" OD will shear at around 1100 ft-lbs. At only 400-ft-lbs of torque as used on most Panteras, the inner bearing spacer, again of mild steel, will indent against the much harder bearing races and get shorter over time, running 400-500 bhp through the assembly. Some shops and owners face the spacer smooth so it looks nice. Re-tightening the nut with a now slightly shorter spacer forces the nut to thread down the axle a little further. At some point, the axle runs out of threads so the nut is really tight but the sandwiched assembly is a bit loose. Bingo- another 'bad wheel bearing'.

View This Reply The De Tomaso Forums https://pantera.infopop.cc To adjust your email notifications for this site, please update your notification settings. To suspend ALL email notifications from this site, click here. |

|

Thanks. On Wednesday, June 3, 2020, 09:56:04 AM EDT, The De Tomaso Forums <alerts@crowdstack.com> wrote:

Reply By davidnunn: Rear wheel bearings

| == To reply by email, write above this line. == |

|

| |

| Hello, old7: We're sending you this notification because you are either following the forum, the content, or the author listed below. New Reply To Topic

| Subject: Rear wheel bearings Reply By: davidnunn In: Technical Information Forums / Gearbox - Clutch - Half Shafts - Rear Axles | |

"It is more advisable to replace the outer bearing with a double row ball bearing because it is it who is the most loaded, but that forces to deepen its housing in the Hub."

Just to clarify; in order to do this, you have to modify the upright, by machining the outer bearing recess deeper by a significant amount.

View This Reply The De Tomaso Forums https://pantera.infopop.cc To adjust your email notifications for this site, please update your notification settings. To suspend ALL email notifications from this site, click here. |

|

Reply By rene4406: Rear wheel bearings

| == To reply by email, write above this line. == |

|

| |

| Hello, old7: We're sending you this notification because you are either following the forum, the content, or the author listed below. New Reply To Topic

| Subject: Rear wheel bearings Reply By: rene4406 In: Technical Information Forums / Gearbox - Clutch - Half Shafts - Rear Axles | R |

The best would be a milling machine with a boring head but I didn't have one yet (I only bought one last week) and I used a lathe with a 4-jaw plate

And here is a link to a video:

https://youtu.be/n7Sx6j_BMig

Since I reassembled the hubs and everything is fine.

View This Reply The De Tomaso Forums https://pantera.infopop.cc To adjust your email notifications for this site, please update your notification settings. To suspend ALL email notifications from this site, click here. |

|

Thanks Rene -

Nice fixturing, I am sure it took you a while to get that assembly running true on your lathe. I am sure the second upright was dialed in much quicker.

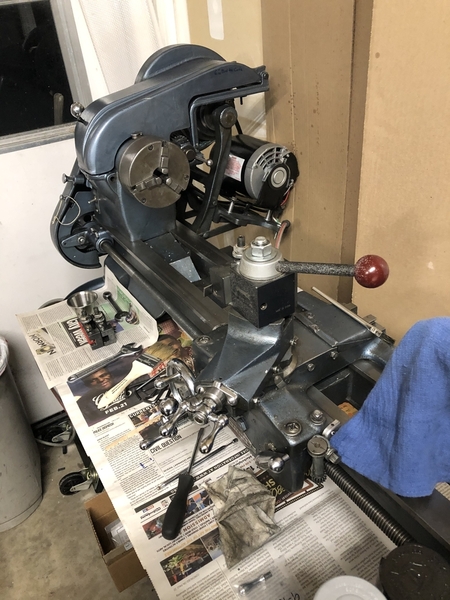

I am taking classes for my next career as a machinist, but I don’t think my Atlas 12” swing lathe could handle this job!

Thanks for taking the time to post up the video. Very cool.

Rocky

Attachments

Yes, it was long because the position had to be very precise, +/- 0,01 mm, or +/- 0.0004 ''

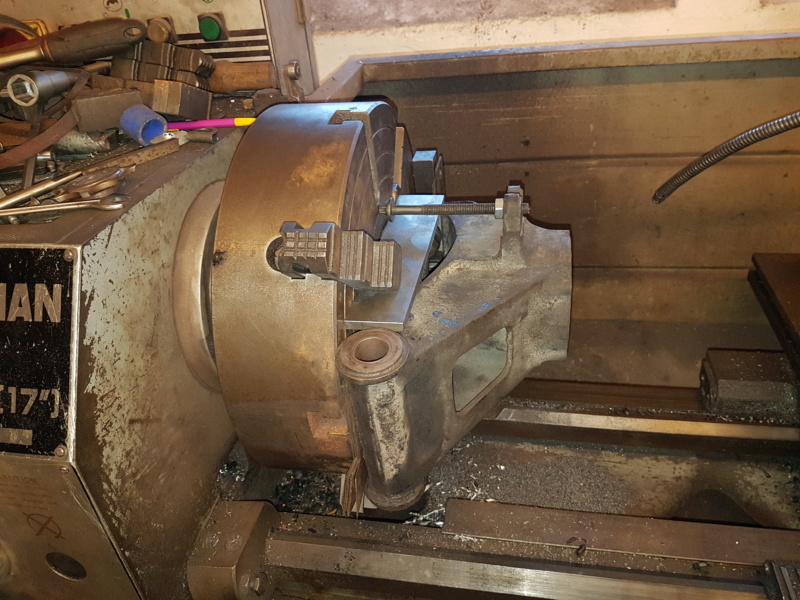

Fortunately I have a big lathe with a maximum diameter of 17 '' and a length between centres of 5 feet

and now I also have a milling machine for operations that are impossible to perform on a lathe, but it is not yet installed.

Attachments

Very nice shop. Enjoy the new mill!

You will be the most popular guy in town with all your car buddies.

Rocky