Hey,

Thanks for the breakdown on what all the numbers mean. I had no idea.

Doug M

Doug,

Is this located on the lower edge? Left, right, center?? I would have thought that the "AS" number should be visible so that an inspector can confirm that the glass is approved for use as a windshield.

Yes, I have the same markings.

My pleasure.

John

quote:The small printing in the photo is right on the edge of the glass and would be covered by the rubber.

Is this located on the lower edge? Left, right, center?? I would have thought that the "AS" number should be visible so that an inspector can confirm that the glass is approved for use as a windshield.

quote:Do you have the DT DOT 177 LAMINATED visible in the bottom corner of yours?

Yes, I have the same markings.

quote:Thanks for the breakdown on what all the numbers mean. I had no idea.

My pleasure.

John

Sorry, the window is all packed up again but if I remember correctly it was in the middle of the right (passenger) side.

Doug M

Doug M

Thanks Doug

John

John

OzGT5 (Guest)

Excellent work mate, thanks very much.

Strange about that measurement across the base. Roland came back at 1550, but that can't be right based on your numbers and mine also.

Yours: 1506

My Safevue: 1493

Maybe he made a typo on that number.

Well this has been a great thread, and it really looks like the current crop of Mexican made Wilkinson windscreens will do the job well.

Strange about that measurement across the base. Roland came back at 1550, but that can't be right based on your numbers and mine also.

Yours: 1506

My Safevue: 1493

Maybe he made a typo on that number.

Well this has been a great thread, and it really looks like the current crop of Mexican made Wilkinson windscreens will do the job well.

OzGT5 (Guest)

I have purchased the original factory windscreen rubber from Roland in Hamburg and this has now arrived in Oz. Very nice, soft and pliable.

There was only one windscreen available in Australia and I had it shipped the 2000 km from Queensland, only to find today that it is exactly the same size as my Surevue that came out.

The installer fitted the rubber to the QLD Oz screen and placed it into the hole, and was able to confirm that the screen ideally should be 5-7mm each side larger to fit properly.

So overall measurements 10 - 14mm each direction larger. The new rubber on the glass doesn't even cover the bodywork when fitted. Looking at the information here, it appears quite common to put a bit of 3/16 cord in the slot first and then the glass so the rubber stretches a bit and the screen doesn't need to have so much recessed into the rubber and this inturn would provide a bit more body coverage.

They are looking at the glass mould to see if they can produce another screen about 10mm larger using the same mould.

So the baby sits in the shed. Near a month now, with no glass in it whilst the sun is shining and Summer aproaches.

Life sucks!

There was only one windscreen available in Australia and I had it shipped the 2000 km from Queensland, only to find today that it is exactly the same size as my Surevue that came out.

The installer fitted the rubber to the QLD Oz screen and placed it into the hole, and was able to confirm that the screen ideally should be 5-7mm each side larger to fit properly.

So overall measurements 10 - 14mm each direction larger. The new rubber on the glass doesn't even cover the bodywork when fitted. Looking at the information here, it appears quite common to put a bit of 3/16 cord in the slot first and then the glass so the rubber stretches a bit and the screen doesn't need to have so much recessed into the rubber and this inturn would provide a bit more body coverage.

They are looking at the glass mould to see if they can produce another screen about 10mm larger using the same mould.

So the baby sits in the shed. Near a month now, with no glass in it whilst the sun is shining and Summer aproaches.

Life sucks!

OzGT5 (Guest)

The installer came back to me today. It looks like it is possible to make a screen 10 - 12mm larger than my Safevue screen using the current mold that they have in Queensland. This means that the screen will fit firmly into the rubber and the rubber will press properly against the frame of the car and seal well.

Same money but delivery time is the issue being 4 - 5 weeks minimum. Car has been off the road for four weeks now, so it looks like I won't be driving it again this year.

Ah well, I've had it for 1 1/2 years so far and have done 850 miles, with 600 of them being in one weekend.

Cars, same days you wake up just hating them!!

Same money but delivery time is the issue being 4 - 5 weeks minimum. Car has been off the road for four weeks now, so it looks like I won't be driving it again this year.

Ah well, I've had it for 1 1/2 years so far and have done 850 miles, with 600 of them being in one weekend.

Cars, same days you wake up just hating them!!

Theres a saying...

If its got t*ts or wheels your going to have problems with it! LOL 4/5 weeks will go by fast and you'll be back to lovin the car again! It will be worth the wait.

If its got t*ts or wheels your going to have problems with it! LOL 4/5 weeks will go by fast and you'll be back to lovin the car again! It will be worth the wait.

OzGT5 (Guest)

Sh1t, I'm stuffed for life then, with a wife and 10 cars no wonder I wake up every morning in a daze!

Robert,

Look on the bright side, that's a lot better than if it were 10 wives and 1 car

Julian

Look on the bright side, that's a lot better than if it were 10 wives and 1 car

Julian

OzGT5 (Guest)

Bloody hell Julian, don't wish that sort of trouble on any man.........

Actually the good lady wench is painting the windscreen channel as we speak. She has the steady hand and the good eyes, whereas I'm an old blind bastard!

Actually the good lady wench is painting the windscreen channel as we speak. She has the steady hand and the good eyes, whereas I'm an old blind bastard!

WOW Robert...

She's working on the car!? Good for you!...Does she have a Sister??? lol I would love to move to Australia!

Curt

Don't need 10, might be interested in 1?

She's working on the car!? Good for you!...Does she have a Sister??? lol I would love to move to Australia!

Curt

Don't need 10, might be interested in 1?

OzGT5 (Guest)

Yes Curt, standing rule. If she want's to drive em, she has to help fix em!

Besides, she's a right pain in the arse. I'm fitting the suspension back in and she says, you painted all of those arms, brackets and bars, but what about the bolts?

I told her that it's very difficult as the spanners tear off the paint, especially on the control arm bolts as they have to be done up damn tight.

She says, no worries, and proceeds to paint every exposed bolt head under the car in gloss black, by hand!

What was I going to say, no? So I did what any sane man should do and left her alone to do it.

Besides, she's a right pain in the arse. I'm fitting the suspension back in and she says, you painted all of those arms, brackets and bars, but what about the bolts?

I told her that it's very difficult as the spanners tear off the paint, especially on the control arm bolts as they have to be done up damn tight.

She says, no worries, and proceeds to paint every exposed bolt head under the car in gloss black, by hand!

What was I going to say, no? So I did what any sane man should do and left her alone to do it.

OzGT5 (Guest)

Oh, and yes! She's a twin!

OzGT5 (Guest)

See, she is doing it. I turned around from my bench as I posted above and took this.

Then I had to take her shoe shopping to the Mall.

Oh, the price we pay.

Then I had to take her shoe shopping to the Mall.

Oh, the price we pay.

Attachments

Great shot, Your a lucky man! So...lets hear about the Sister! lol

OzGT5 (Guest)

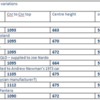

Well the variation in screens for these cars is nothing short of amazing.

Here's a small table of ACTUAL windscreen glass that has been measured whilst looking for glass to fit into my car properly.

Here's a small table of ACTUAL windscreen glass that has been measured whilst looking for glass to fit into my car properly.

Attachments

OzGT5 (Guest)

The size variation is astonishing. My Safevue USA glass was leaking terribly into the car and on inspection I found that it wasn't more that 1 - 2 mm inside the rubber. I have purchased a new factory original rubber from Roland Jaekel in germany and when I fit this rubber to my safevue screen it's at least 10mm too small to fit the car properly.

My screen needs to be 1505 / 1104 / 672 / 592 to fit the car properly.

As I get more data I will add to this spreadsheet so we have a comprehensive fittment guide.

My screen needs to be 1505 / 1104 / 672 / 592 to fit the car properly.

As I get more data I will add to this spreadsheet so we have a comprehensive fittment guide.

Hej Robert,

very interesting indeed! It is great to see a database of info on this. It would be interesting to know if there is a difference between the different Panteras (e.g. pushbutton versus pre-L, versus L, versus GT5 etc), which explains this.

Cheers, Tim.

very interesting indeed! It is great to see a database of info on this. It would be interesting to know if there is a difference between the different Panteras (e.g. pushbutton versus pre-L, versus L, versus GT5 etc), which explains this.

Cheers, Tim.

OzGT5 (Guest)

Yes Tim, but I think we need someone like Kirk to come along and assist us with that knowledge.

The variations in glass are strictly manufacturing quality issues. the bodies will vary on late model cars and very early push buttons but the glass should always to be the same size. You can make even the poorest fit class work but the time involved and modifications required to seal it are difficult.

I built a new windscreen/windshield master for the new body design several years ago that kept the upper roof and A-pillars the same but extended the lower bottom fitment out all most a foot which raked the glass significantly.

Here is a side profile shot of the shape installed into a Pantera. You can clearly see the increase in rake but still maintaining the A-pillar rake---not relevant to the thread---just another trip down memory lane where I stubbed my toe. ( )

)

I built a new windscreen/windshield master for the new body design several years ago that kept the upper roof and A-pillars the same but extended the lower bottom fitment out all most a foot which raked the glass significantly.

Here is a side profile shot of the shape installed into a Pantera. You can clearly see the increase in rake but still maintaining the A-pillar rake---not relevant to the thread---just another trip down memory lane where I stubbed my toe. (

Attachments

Kirk, if you're going to all the trouble of making a new cowl panel, why not drop the lower area where the glass sets, and rig the Pantera to have real disappering wipers? Sure, it would take new glass, but that's what this thread was all about, and maybe a sharpie like you could find a deep windshield from a Z-28 or something that would fit the new configuration?

BTW, I tried to e-mail you last week; please send me a post at

BTW, I tried to e-mail you last week; please send me a post at

Jack,

It is/was dropped into the cowel and the wiper would have disappeared. Sorry I did not read the post from the beginning---Robert emailed me to possibly add to the post.

Also---I'll be sending the copy you requested.

Kirk

It is/was dropped into the cowel and the wiper would have disappeared. Sorry I did not read the post from the beginning---Robert emailed me to possibly add to the post.

Also---I'll be sending the copy you requested.

Kirk