> It's a hydraulic roller cam.

> Int Exh

> Avg Duration: 276 290

> Dur @ .050: 220 230

> Valve Lift: .591 .588

> Lobe Sep: 106

Are you sure that 106 is the LSA and not ICL (Intake Centerline). Most of

Comps street grinds are on a 110 LSA but are installed 4 degrees advanced on

a 106 ICL. Do you have the cam card? If it really is a 106 LSA, that's too

narrow for a 351C with the sort of duration and specs you are talking about.

> I want a "HIGH REVVING" 6,500+ Cleveland that will idle nicely & PULL throughout the powerband!!!

A 106 LSA with 220/230 degrees @ 0.050" is not going to idle well or make

very good power. The 10 degree intake/exhaust split only makes things worse.

I went too narrow on the LSA for the 351C dyno mule. That cam was:

228/232 degrees @ 0.050" lift (280/284 @ 0.006"), 0.588"/0.588" lift,

107 LSA, 68 degrees overlap, installed in the engine on a 104 intake centerline.

We picked the cam specs before I had access to Dynomation (the tool I now use

to design cams). I used Vizard's cam spec rules-of-thumb and came up up with

a compromise cam since we were testing a bunch of different heads (iron 2V and 4V,

CHI 3V, Pro Comp, A3 and C302B high ports, etc.). However, I made a mistake and

subtracted 2 degrees from the LSA for canted valves when I should have added

2 degrees so the LSA was off. Later I re-designed the cam using the Dynomation

simulation program. I validated the simulation model using dyno data gathered

from several 351C, 393C and 408C engines on Dave McLain's dyno. The new cam came

in with specs:

228/234 degrees @ 0.050" lift (282/288 @ 0.006"), 0.620"/0.580" lift,

111 LSA, 63 degrees overlap, installed in the engine on a 106 intake

centerline.

If I had added 2 degrees to 109 instead of subtracting, I would have also

gotten 111 degrees using Vizard's simplified rules-of-thumb. Compared to

the original cam, the simulation suggests it's worth about 20 HP at 5800 RPM,

being better everyhwhere in the RPM range. Vizard's testing suggest that

109 degrees would yield similar performance but have a rougher idle. Narrow

it further and you'll start to give up power and have worse manners.

Here's a right up I did a while back on Vizard's rules of thumb. These are

simplifications of what his cam design software does but yield a good starting

point and check on my Dynomation simulations.

In "Be the Camshaft Expert" (July 2006 issue of Popular Hot Rodding) David Vizard

presents some rules of thumb for selecting cam specs based upon what he's learned

in developing a cam selection program. The program was reportedly 18 years in the

making and uses data gathered from several thousand cam tests. The basic idea is

that. for a given engine, there is an ideal lobe separation angle that works best

over a relatively wide range. This ideal LSA is primarily a function of cubic inch

displacement (CID) per cylinder per inch of valve diameter, as well as compression

ratio and valve inclination (canted or inline). Once ideal LCA is known, you pick

the desired overlap via application:

1. Street towing 10 to 40 degrees

2. Regular street 30 to 60 degrees

3. Street Performance 50 to 75 degrees

4. Street/Strip 70 to 90 degrees

5. Amateur Race 85 to 100 degrees

6. Professional Race 95 to 115 degrees

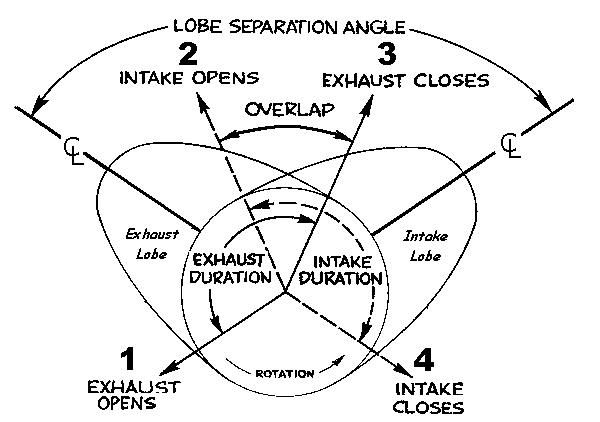

Overlap is the period when both intake and exhaust valve are open and serves

to set the RPM range over which the cam will be best suited. More overlap

means a rougher idle and poorer low end response due to reversion of the

exhaust charge into the intake plenum as well as loss of "effective"

compression ratio (compression is literally blown out the exhaust port at

low RPM). Where you fall in the overlap range is a function of valve size

per cubic inch. Big valves on a 302 use the low end, a 350 with typical size

valves use the mid-point, big inch small block or big block, use the right

hand side. Cam overlap sets the RPM range in which an engine will best operate

and the total overlap is a function of the cam duration and lobe center angle

(LCA). If you know the ideal LCA and the RPM range you wish to operate in,

the duration falls out of the equation.

In the article, Vizard presents graphs of cubic inch displacement (CID) per

cylinder per inch of valve diameter versus ideal LCA. The graphs are for inline

valve heads with compression ratios between 9:1 and 11:1. If canted valve heads

are used, the ideal LCA is adjusted by adding 2 degrees to minimize the reversion

(canted valve heads are more susceptible to reversion than typical inline valve

heads). The optimal LCA is also adjusted for compression ratios outside the assumed

range. Once LCA and overlap are known, duration falls out of the equation. Maximum

lift is a function of the intake valve diameter. Large valve heads will continue

to gain flow for relatively large lifts so the maximum lift for a Cleveland is

usually set by other considerations (seat and valve guide lift, piston-to-valve

clearance, etc.).

In the article, Vizard presented the results of a test demonstrating the

importance of picking the right LCA:

http://www.bacomatic.org/galle..._comparison.jpg.htmlIdeal LCA for that engine was 108 degrees. Narrowing to 105 degrees made

similar power but had noticeably worse idle and low speed characteristics.

Widening to 111 degrees lost power. Another LCA test was performed on a

302 Small-Block Ford and repeated on a stroked (347 CID) version of the same

engine:

http://www.popularhotrodding.c...basics/photo_12.html"When used in the 302, the 276/280 roller hydraulic cam on a 110 LCA proved

optimal, as even a 1 degree change either way produced worse results. Using

a SCAT stroker kit, this engine was stretched to 347 inches and re-tested

with the original 110 LCA cam. The stroker kit really helped both power and

torque. When the 110 LCA was replaced with a more appropriate 108 LCA cam,

the output made a further jump to the tune of some 20 lb-ft and 20 hp. The

108 cam in the 347 gave as much in terms of idle and vacuum as did the 110

LCA in the 302. Dozens of tests such as this show conclusively that the

overlap and LCA--not the duration--are the first steps toward generating a

cam spec."

At low speed, lots of overlap is bad as it hurts low end but overlap helps

as the RPM increases. To a degree, you can offset overlap with static

compression. Another point raised in the article is that, for most V8's with

reasonable heads, the ability to raise low speed torque with compression

increase holds to around 285 to 290 degrees (at lash point) of cam duration.

After that, drop off is faster than an increase in compression can recover.

In another article ("Compression Comprehension") about running up to 12:1

compression on pump gas, Vizard presented the results of a compression test:

http://www.bacomatic.org/galle...peed_output.jpg.html"When used in conjunction with a bigger cam, increased compression can

work wonders for the entire curve. When a 265-degree cam (gray curve)

was substituted for a 285-degree cam (blue curve), a substantial drop

in low-speed output was seen. Raising the CR from 9:1 to 12:1 recovered

almost all the lost low end and gave a further increase in top-end

output"

I wrote a little computer program based upon the article. The required

inputs for the simplified program are:

bore diameter (in inches)

crankshaft stroke (in inches)

intake valve diameter (in inches)

static compression ratio

canted or inline valve heads

desired overlap (picked from the ranges listed above)

Vizard's cam selection program is not available to the general public but I

know for a fact it takes much more into consideration than the simplified

rules presented above. A friend has run his program and it uses actual head

flow data, port size (length and cross-sectional areas), valve diameters,

rocker ratios, desired idle vacuum, compression, bore, stroke, fuel octane,

thermostat temperature, rod length and more. Basically, it attempts to feed

the "air pump" in the most efficient manner, given the parameters entered.

What it doesn't do is tell you what ramp rates you need. The recommendation

is to use the most aggressive ramp you can tolerate for your application.

However, more aggressive lobe shapes are noisier, wear more quickly and are

harder on valvetrain parts so that neds to be taken into consideration as

well.

The simplified program assumes you'll use the same lobe profile for intake

and exhaust. There's also an implicit assumption that the exhaust flow is

reasonable compared to the intake. Vizard also suggests the rocker ratio

on exhaust is best kept 0.1 to 0.2 of a ratio lower than the intake ratio.

The exhaust is under higher pressure and blows down early in the lift cycle

plus the exhaust is less sensitive to valve acceleration than the intake but

is sensitive to duration. I noticed in the Engine Masters Competition, most

of the entries were using shorter rocker ratios. I tested this on the dyno

mule 351C and we did indeed pick up average power (mostly in the mid-range).

If an existing cam's LCA is too wide, higher ratio rockers may increase output.

For rocker ratios between 1.5 to 1.9, each 0.1 ratio increase on the intake,

the LCA needs to be spread by 0.75 to 1. Be aware there are cases where the

ideal lobe center may be too narrow for acceptable street manners. For instance,

when stroking an engine (keeping all other variables constant), Vizard suggests

tightening the LCA up by a degree for something like every 16 cubic inches

increase in displacement. That will lead to very tight lobe centers which may

not be acceptable for certain applications. For instance, an engine equipped

with mass-air EFI (which will measure reversion flow as if it were induction

flow) might not be too happy with 104 degree lobe centers. Vizard's full-up

program allows you to specify idle vacuum to get around problems like that

but the simplified program doesn't have that sort of flexibility.

Another thing to be aware of is that narrow lobe separation angles require

an efficient exhaust with minimal back-pressure. If you have a bunch of

back-pressure (from things like restrictive mufflers or headers that turn

down sharply at the exhaust port exit) it will hurt a narrow lobe separation

angle engine more than a wide one. A quote from the article drives home this

point home:

"Let's make one thing clear here: Big (but not excessive) overlap is a prime

key to big power numbers, but only if your exhaust system sucks. Literally.

If you have ever heard that an engine needs a little backpressure, you might

want to ask yourself why an engine would want an exhaust system that literally

pushes exhaust back into the combustion chamber rather than sucking it out.

The simple answer is, it doesn't. If a big-overlap, big-cammed engine has an

exhaust system with any measurable backpressure, the price paid is a big drop

in output."

If your exhaust system is restrictive, it may be wise to err on the side of

a wider LCA (better yet fix the exhaust).

Since large valved heads tend to increase flow through high lift levels,

the lift recommended by Vizard's rules may be excessive for heads equipped

with large valves. The recommendation is to use a lift consistent with your

reliability goal (higher lift wears valves, guides and seats more quickly).

More info on Vizard's cam rules can be found at:

http://www.popularhotrodding.c...ft_basics/index.htmlDan Jones