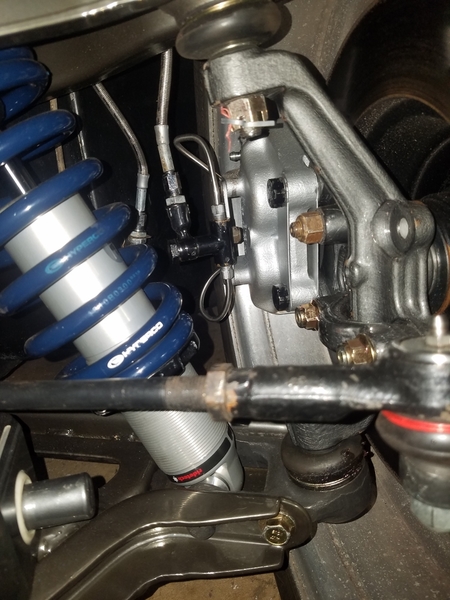

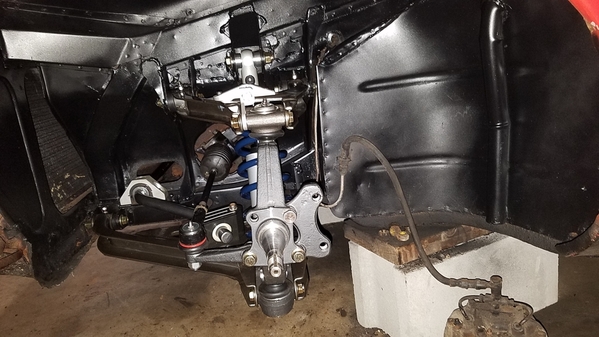

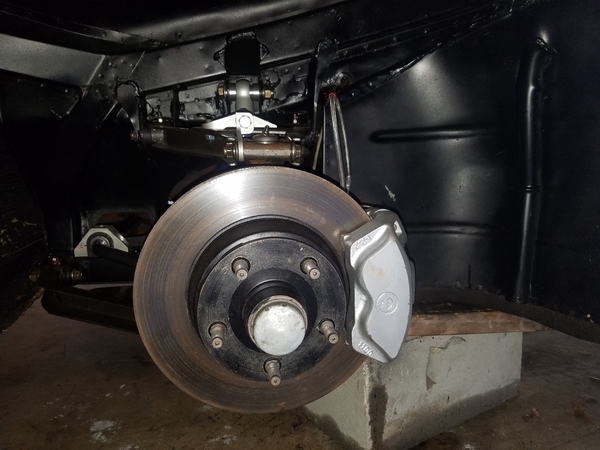

I forgot to mention, I removed most off the old undercoating from the wheel wells. The metal was really clean and rust free! I also replaced the original a-arm bushings (boy were they shot- and fun to get out) with new offset poly bushings from Pantera Parts Connection. I also installed new rear upper ball joints and grease fittings on everything.

I ended up buying a house, moving and selling my old place last summer, so I haven't done much since then, except drive it every chance I get.  The good thing is, I have plenty of space and an air compressor to work on it now.

The good thing is, I have plenty of space and an air compressor to work on it now.

I've recently started working on the rust in the rear hat channels above the wheel wells/engine bay. I knew about this before, but didn't have time to get into it. From the wheel well, it looked really rust free, except at the ends of the channel at the tail lights, it had wasted away. The driver side will all be replaced back to the upright, while the passenger side is good except a 10in section at the taillight. Wish me luck, it's pretty ugly!

![20210311_111449[1] 20210311_111449[1]](https://pantera.infopop.cc/fileSendAction/fcType/0/fcOid/3853791630418945/filePointer/18496584599942544/fodoid/18496584599942538/imageType/SQUARE_THUMBNAIL/inlineImage/true/20210311_111449%5B1%5D.jpg)

![20210311_111434[1] 20210311_111434[1]](https://pantera.infopop.cc/fileSendAction/fcType/0/fcOid/3853791630418945/filePointer/18496584599942545/fodoid/18496584599942539/imageType/SQUARE_THUMBNAIL/inlineImage/true/20210311_111434%5B1%5D.jpg)