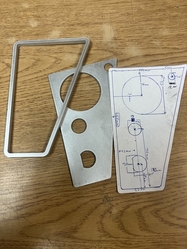

Does anyone have the ability to 3D print, or have a good contact? I'm looking for a small piece to fit in my ash tray cutout to mount switches, about 2-7/8 x 4-3/8 x 1/2 in black plastic. I have 2D AutoCAD drawing, but I don't have the ability to create a 3D printer ready drawing. I've attached a lame photo of a drawing.

Replies sorted oldest to newest

I just rec'd this to blank the ash try cutout

Thanks. I'm trying to create a shallow tray that fits in the ash tray hole that would allow me to mount the Wilwood P-brake switch and phone charger USB port below the level of the surrounding center console to prevent accidently applying the P-brake. I thought that this would be a fun little project, but it appears to be growing. I haven't received the switch yet, which may have some sort of mechanism to prevent accidental engagement, and the whole exercise may be totally unnecessary.

Attachments

You continue to amaze me!

Wow - I had no idea that waterjets had the ability to do 3D work. I'll look into it.

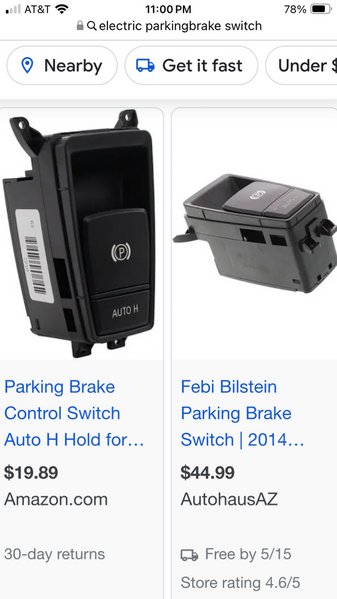

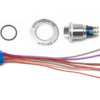

Your switch switching the switch approach looks good as well. I had planned to use the Wilwood switch that came with the unit to simplify wiring - there are a LOT of wires going into the back of that blue plug. On the other hand, there appear to be only 3-4 connectors on the back of the switch. I still haven't received the switch yet, so I don't know exactly what's going on. The switches in your pictures sure look a lot nicer that the Wilwood one below, though.

Your knowledge of what's "out there" is pretty impressive. Thanks!

Attachments

@Ed Harbur posted:Wow - I had no idea that waterjets had the ability to do 3D work. I'll look into it.

Your switch switching the switch approach looks good as well. I had planned to use the Wilwood switch that came with the unit to simplify wiring - there are a LOT of wires going into the back of that blue plug. On the other hand, there appear to be only 3-4 connectors on the back of the switch. I still haven't received the switch yet, so I don't know exactly what's going on. The switches in your pictures sure look a lot nicer that the Wilwood one below, though.

Your knowledge of what's "out there" is pretty impressive. Thanks!

Well, the waterjet can’t do 3D but it can cut parts in different thickness , in my case 1/4” frame and 1/8” center plate and then spot weld together… to CNC that part would be to much $$$

Old saying: “keep it simple stupid!”

Regarding your switch… doesn’t look bad.. it’s a “turn switch “

1) have a parking brake warning light in your face…

2) convenient location is secondary.. I probably would put it next to the hazard switch

If you do use that little switch - when soldering it to the harness, be careful to not leave your soldering iron touching the contacts for too long… they will melt right out of the back of the switch….

Don’t ask me how I know…

Rocky

Ah. NOW I get it. The layered approach. I originally thought of doing it out of pieces of wood or carbon, but moved away from the idea because I was worried there wasn't enough gluing surface. Welding metal, however takes care or that.

Rocky - thanks for the soldering heads up. I can just see myself soldering away and thinking "hey, what's that smell"....

I clearly misunderstood the capabilities of 3D printing. I had imagined sending my 2D drawing and $100 to someone and having the UPS man deliver a finished part 3 days later. Nope.

@Ed Harbur you can make an insert for the ashtray out of cardboard.. I used a cardboard box, fiberglass resin the inside and glassed the outside .. covered with black vinyl…

Attachments

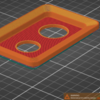

I was trying to come up with a drop in piece to replace the ash tray. I ended up finding a guy that was an ex-Pantera owner who did a great job for me. Quick, inexpensive and exactly what I was after. Still in primer so it's not in its full splendor, but looks really good.

Rich Silberfeld

GreenGate3D

631 969 1051

Attachments

I can 3D print that for you Ed. I'm in France so the majority of your cost will be shipping. PM me if interested...

Dang- thanks very much for your offer, but the piece is done and will be in the car shortly. You'll be the first person I contact next time!