quote:

Originally posted by Fredrik Gustavsson:

quote:

Originally posted by PanteraDoug:

I like it. It's going to be very torky.

What are you going to use for engine management?

As far as the hoses go, what is the problem?

From what I see you are ready to cut the hoses.

Take off the red ends and fit the hose length unitil it is just clear of the threads.

Put the entire fitting in a vice to hold it securely.

Slip the red ends over the hose carefully. The stainless wire bites your fingers pretty well.

Lube up the threads with assembly lube and tighten the red cap leaving about .050" clearance between the red and the blue and you are done.

However, looking at your set up. I would recommend that you buy some stainless tubing.

Switch the ends that you have now to take a flared tube nut and ferrel.

You can polish the tube and you can leave them there forever without having to worry about the rubber of the hose deterreorating.

I will use a

MegaSquirt ECU together with a Ford EDIS ignition system.

About the

assembly instruction:

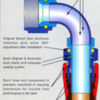

Place the socket in a vise and insert the end of the hose into the socket until the

hose butts against the bottom of the threads provided for the cutter. Gently pull

the hose back until there is a 1/16" to 1/8" gap between the end of the hose and

the bottom of the threads.Exactly how far should the hose go into the socket? Look at the picture "Hose end 2". When assembled; should the hose go further on the cutter?

Assemble them exactly how you have it layed out in #2.

You cannot have any wire extending into the plane of the teeth of the thread. It will strip the soft aluminum teeth off.

Even with the 40psi fuel pressure that the FI pump will make, the hose will hold the pressure with no problem.

It is good for about 800psi.

Make sure the hose is cut straight and clean.

A dremmel with a carborendum wheel works great on these. Wear a particle mask. SS dust exposure is no good for living things.