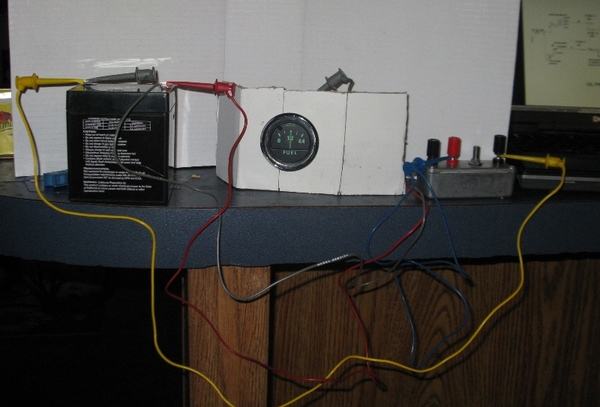

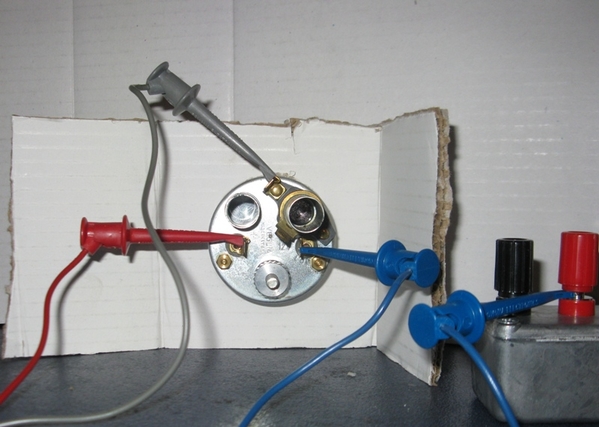

I decided to test my gauges to see if they even worked. I really wanted to make a test stand and harness, BUT I just used a handful of test leads from my days of “keeping the lights on”. For the senders, I had a 1Kohm multi-turn rheostat that I used to do similar for verifying the controls of 2gigawatt thermal nuclear reactors. The battery was borrowed from my trailer “break away brakes”.

My original gauges responded and the sender resistor values recorded. I discovered a spare fuel gauge I picked up off eBay was bad. Even though it was from a “reputable” vendor, it has been a couple years so I guess I just learned a lesson and maybe will take it apart to see what’s inside

A tidbit I learned was that even though SOBill’s drawings imply a case ground not used, it is indeed needed. Actually the bad gauge does not have the internal connection to case ground and thus only responds ½ to full scale with excessive sender range.

The sequence of steps was to;

Connect battery

Adjust rheostat to align needle to mark

Disconnect rheostat from gauge

Measure rheostat ohms and record

Repeat for the 5 points per guage