I haven't found a recent post on the subject so I'm creating one.

I received my camshaft from Schneidercams and I was surprised to find a small fluorescent orange label in the box that says:

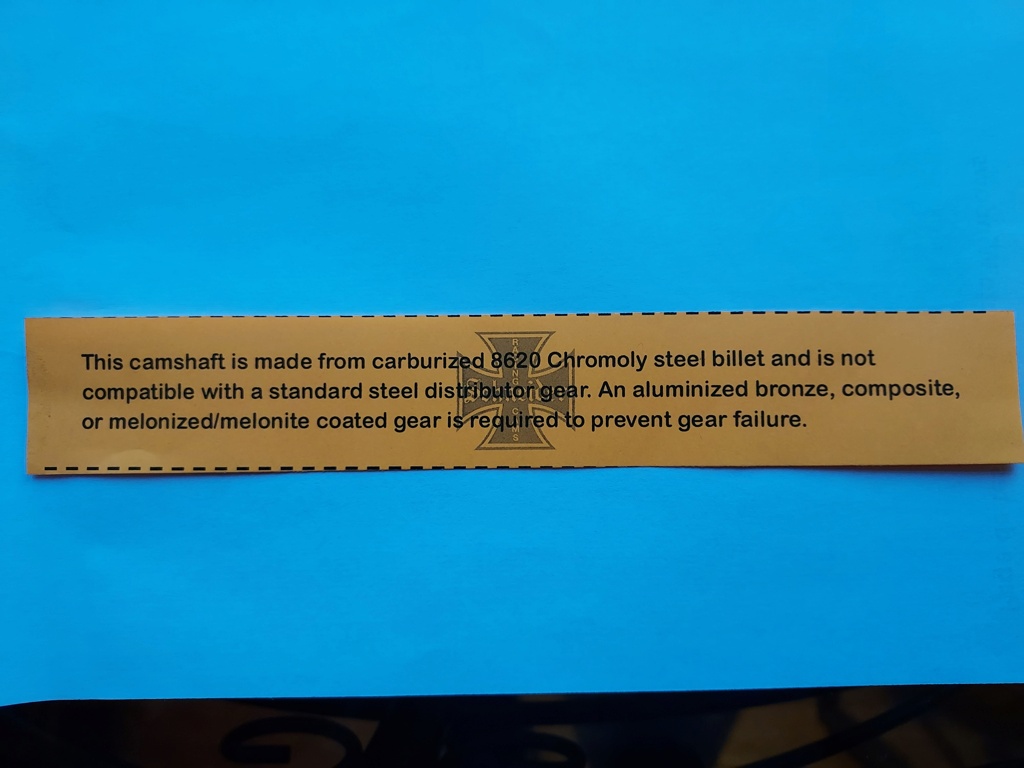

This camshaft is made from carburized 8620 Chromoly steel billet and is not compatible with a standard steel distributor gear. An aluminized bronze, composite or melonized/melonite gear is required to prevent gear failure.

I don't want to use a bronze gear that will wear out quickly and so I have the choice between composite and melonized, what are your opinions and experiences?

Thank you for your contributions et happy new year.