There are 700 to 1000 PSI in the front calipers when I press with all my strength, braced against the seat, which never happens under normal driving conditions, especially with a car that does not have ABS. I will perhaps repeat measurements by pressing on the pedal with a force comparable to that applied during emergency brakes.

I find it a shame to neglect the rear brakes on a car which has 60% of its weight on the rear wheels and which is designed to brake flat with therefore little load transfer. But I know that it is imperative that the rear wheels do not lock before the front one.

I agree about the rears needing a better solution then stock but finding that exact correct pressure is somewhat of a challenge.

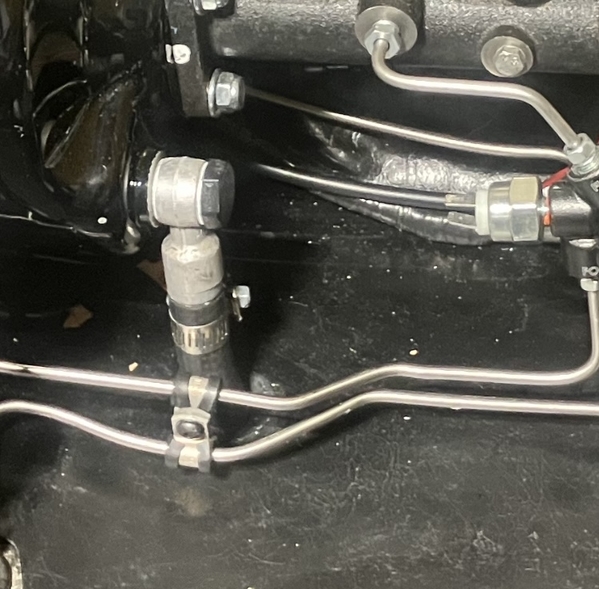

I would prefer rear brakes that are unnecessarily big, commonly available and then just adjust the pressure down until balanced with the front. That is my intent.

I could only get about 700psi in the front. My leg isn't as strong as yours?

I am looking at what the Group 4 cars ran and the big rotors appear to be the thinking for the time? I think though that the choices were limited in comparison to what we can do now? The thought that brakes that large in the rear can be done is encouraging.

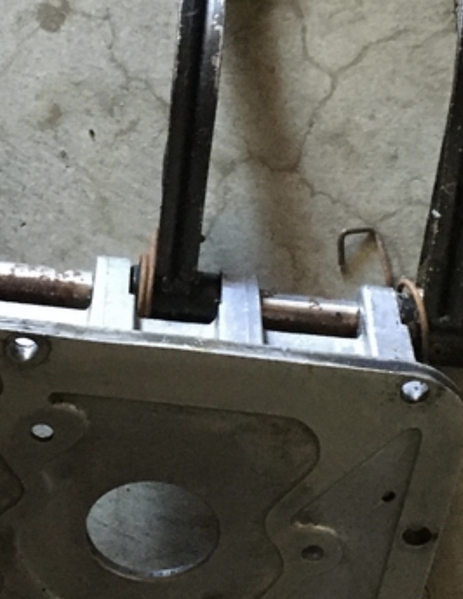

In particular I noticed the vented rotors, the thickness and the outside diameters. The calipers appear to be the same aluminum single piston that were used on the race Cobras and the GT40's. I know that the Cobras were using solid, non-vented rotors. I don't know about the GT40's.

The Detomaso factory parts illustration shows front and rear race rotors looking equal and resembling the 1969 Ford "Big Ford/Lincoln", 12"od x 1.25" thick vented? I am using those in front and know that they fit and apply themselves well in the front.

I'm sure that was done to give the rotors greater longevity in racing conditions but that much rear braking required adjustments to the rear pressure for certain.

I never even saw a suggestion in old magazine articles as to how that was done? Neither had I read that the race cars lacked braking.

That was the largest issue that the Ford GT40's had at Lemans. Brake durability. On the street we no longer need to concern ourselves overly on that subject.