When I asked this same question about pilot bearings not that long ago to Wilkinson he set me up the Ford pilot bearing. The same thing Doug is saying. Wilkinson has a bunch of them at his shop and they are reasonably fresh.

All the information that you need to know really is posted here in this thread. The cautions are here. The cautions are explained about the materials.

Looking at the bushings and bearings readily available no one is specifying magnetic or non-magnetic. You will need to ask that before you buy.

I do know that in addition to the oilite variations out there, there was also a solid bronze bushing at one time. It was also non-magnetic but contained no lubricants.

I personally would add that the pilot roller bearings in my experience are not what you want to use. They have no advantages and present some additional potential issues.

The simplest way to deal now with the controversy is to use an OEM Ford. You have to do your homework and actually search for one, like maybe call one of the Pantera parts vendors? Sometimes it appears that all of "us" take too much for granted and expect everything to just fall in out lap like ordering a Big Mac and having it delivered?

There is a D0AZ-7600-A Ford bushing that is also out there. It superseded the C8. The way Ford Service Parts works, it should also be essentially the same but I don't know that as a fact and what is different if anything, about it?

In reality, this isn't all that complicated but there are a bunch of novices here that need some very simple things explained to them. Some of us are trying.

Everyone will understand that I will not answer.

FWIW, M.I. Bearing claims to have OEM FORD D0AZ-7600-A bearings for 2.73 plus $15 shipping each. I have no idea if this is the best option, if it's even the same or if this one is genuine, but for $2.73 I bought one to throw in my box of parts for "some day".

Thank you Ed. Can you post a link to it?

I'm not sure if they are exactly the same? Ford's normal procedure is to update the parts.

Usually this just means that the engineering criteria is the same or improved but they can look different then the "original Production line" part.

So for things that are important to "restorers" parts that are exposed in displaying the car in a show competition, that has always been an issue and why there are some very expensive parts out there for sale.

In the case of this bushing, it is strictly the function that is the consideration.

I thought you made a typo on the price?

Someone who has done a lot of Pantera engine/tramsaxle work like Ron Mccall would be the guy to ask about this though. Wilkinson, although helpful, is not a mechanic that might be aware of special issues with the ZF application? It would take time and mileage on the part to show a problem. How many miles? Who knows for sure? Best to be safe,

https://mibearings.com/index.p...p;products_id=153216

I'm going to send mine to Ron, who should be installing my ZF right about now...

Just to expand the knowledge base a little…

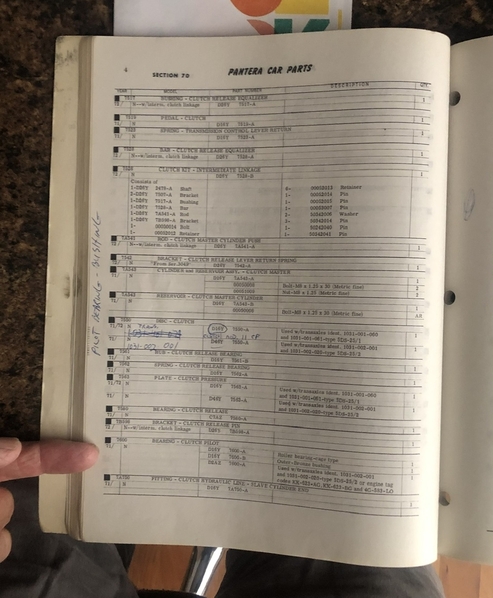

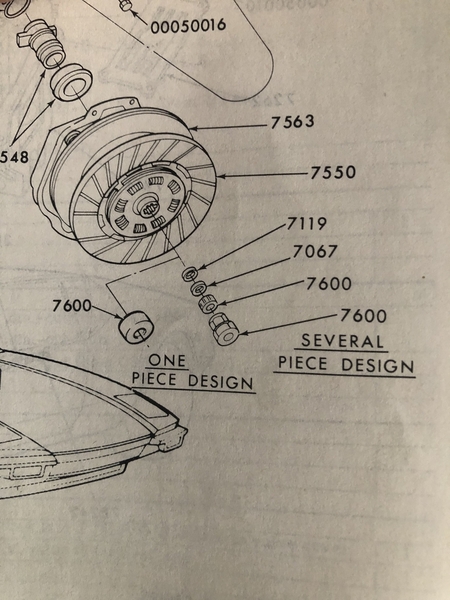

The first picture below is the page from the Orange (‘71 - ‘74) Pantera Parts Book. As Bosswrench called out in another thread…. Both the bearing 7600-A, and the bushing (7600-B) are listed (I’m using Ford’s terminology here).

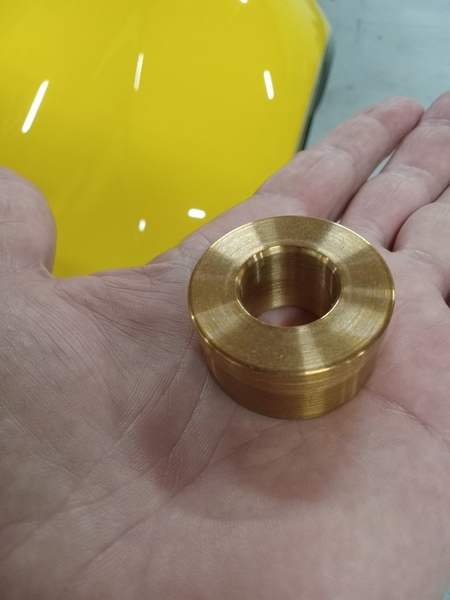

The second picture is a Ford Bushing that came out of Ken Daniel’s car.

I can’t say if the part number on the box (even though it has the 7600-A designation) applies to the bushing…. Just that it was in the box.

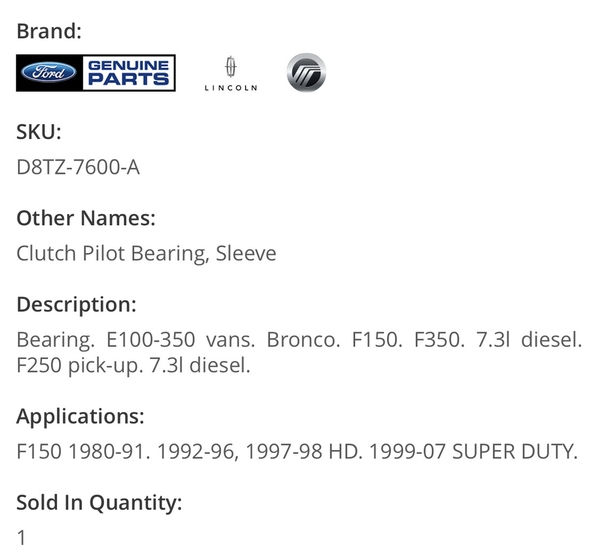

QUICK FOLLOW UP: The D8TZ is from a different (and later application)… see third picture…

KD was a hot-roddler, built many high-performance engines, and ran his car at Silver State, so that Ford box might have been from a bearing he installed, and then he just put the used bushing in it.

Rocky

Attachments

@Ed Harbur posted:https://mibearings.com/index.p...p;products_id=153216

I'm going to send mine to Ron, who should be installing my ZF right about now...

I just now ordered three of them. One for each of my cars currently along with one for the next car. The cost comes to $6 each.

So the M.I. Bearing is a bearing as opposed to bushing. I am watching this because the clutch setup on my new GT uses a 17mm sealed bearing as well, not a bushing.

There was discussion of bushing v. bearing a long time ago. It might have been in the early '80s when Ford reintroduced the Mustang GT? I do not remember the date exactly or the circumstances.

I do remember trying a roller bearing when I did a clutch in my 82 Van. It did not last long but I noticed no damage to the nose of the transmission.

I see no advantage to a roller bearing. Bearings fail. Bushings do not. The simpler solution is always better.

I have no way of proving, one way or the other, if the input shaft of the ZF is hardened or not. I do find it difficult to believe that it would be just plain tool steel? The simple test that I was taught was that a file will not "cut" a hardened part.

There are degrees of hardness and that is reflected in the Brinnel test. That is commonly done on crankshafts and you will see evidence of it with a dimple in a non structural area of the crank. The deeper the dimple, the softer the crank.

Cleveland cranks in particular were tested for hardness. The harder ones were used in the higher performance applications since they are all nodular iron. Theoretically, the Boss 351 got the hardest.

To what degree the ZF transmission input shafts are hardened, I don't know. I never came across that data or a discussion of it. I do know that Ford was not impressed with the ZF in general and had many criticisms.

It would make sense since the shaft is going to be subject to twisting, bending, tensile and shear loadings and hardening it improves the strength across the board.

The pictures I am seeing of the ZF mainshaft and the transmission disassembled are looking to me like I see the blackening from the hardening process.

I can't argue one way or the other if it is hardened or is not but I accept the caution to use a low iron, high copper bushing.

Anyone with one out of the car can do the file test on the nose of the input shaft though. That will answer the question.

Oh well.

A quick Google search showed a number of other sources for between $6 and $10. https://www.ebay.com/p/1011169142. This looks a bit different than the one removed form Ken Danial's car.

@Ed Harbur posted:Oh well.

"Sadly we are out of stock and you have been refunded.MIBearings LLC"A quick Google search showed a number of other sources for between $6 and $10. https://www.ebay.com/p/1011169142. This looks a bit different than the one removed form Ken Danial's car.

Hope springs eternal!![]()

Yes, the D8TZ-7600-A looks like a caged needle bearing in an adapter housing.

Certainly is different than the bronze one that was in the box…. But the parts book shows both, as Jack mentioned in another thread…

(I’m pretty confident now that box isn’t the one that goes with the bushing…)

Attachments

Oh Shit! Someone tossed a bucket of chum in the water!!

After over 30 years in the firehouse you know not to let anyone know that they got your goat. If you do, it’s open season!

Since you are holding it, take a quick measurement on the o.d. and i.d. I don't need 15 significant numbers. o.d. is 1.375" and i.d. 0.669" or 17 mm? thank you

It’s a thing of beauty. I’d like to have one.

To me it sound like a cram. Must be my twisted sense of humor!