If MarlinJack is no longer making his oilite bearings what is everyone doing?

Replies sorted oldest to newest

Just use a pilot bearing.

I think any turner can make a ring if they are told the dimensions. Maybe Marlin Jack can point them out?

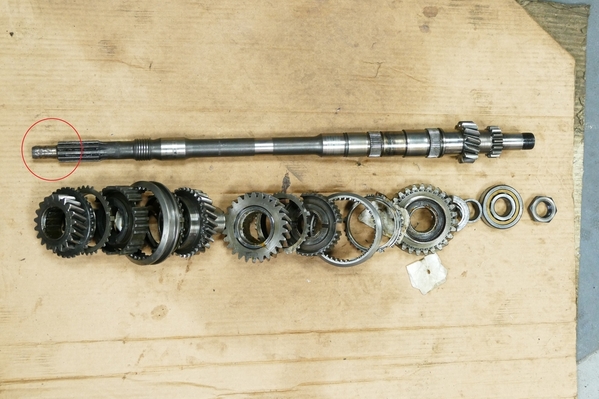

I made one myself in bronze which I adjusted to the diameter of the input shaft after having ground and polished it to eliminate traces of corrosion and soaked it in hot oil.

I made it wide enough so that it could accommodate a sealing ring.

Unfortunately I did not note the dimensions, I did not think it would be useful but it is easy to measure the external diameter on an old ring or an old bearing and an internal diameter larger than the input shaft by 0.05 mm will work fine.

Attachments

Thank you Rene. Nice work !...

I found this one McLeod 8-2380-2, states it is bronze oilite, outside dia 1.380", inside dia 0.670, see link below.

https://www.mcleodracing.com/p...shings-8-1380-2/p130

Won't this work? It is $25.00 I need to buy one for my re-built ZF and new clutch.

Larry

Sorry, I didn't mean to "offend" you at all but:

- You are not the only machinist in the world who knows how to work with precision

- These bearings, or rings, or bushings whatever you want to call them, are not high-tech elements, you shouldn't exaggerate either.

- Extreme precision is useless, this ring does not undergo any effort, it just serves as a guide to prevent the input shaft from vibrating and rubbing against the differential housing, no need to look for the micrometer for that .

We all like you well here and recognize your great skills but frankly, your bad moods attacks are sometimes annoying.

No hard feelings? ![]()

I would ask Dennis Quella, Ron McCall, Larry Stock or Steve Wilkinson what they use.

OK,.... So.... MarlinJack, Is it 841 or what? Your machining expertise is well known and recognized around here.

If your not going to make them anymore can you confirm the material?

@marlinjack posted:...I Love That! "Precision is Useless"! You're Arrogant!

I'm trying to calm things down and you insult me!

You say that I am arrogant because you know that while you were in VietNam, I was studying engineering in one of the best French engineering schools and I learned there that it is useless to be more precise than necessary.

I also learned that when the coefficient of expansion of the material of the internal part (between 14.5 and 17.5 for bronze) is higher than that of the external part (11 for steel) the internal part cannot come out all alone because of the heat, on the contrary.

This isn't the first time you've made mistakes and you're upset because I see them. I do it too, but it doesn't offend me if it's pointed out to me.

For me the discussion is closed, it no longer interests me.

Can someone confirm the pilot bushing or bearing i.d. spec for the typical Dash - 2 ZF is 17mm? I am working on spec'g a clutch for my car.

Also, what is the o.d. of said bushing / bearing for the hole in the crank?

thanks

@panterapatt posted:Can someone confirm the pilot bushing or bearing i.d. spec for the typical Dash - 2 ZF is 17mm? I am working on spec'g a clutch for my car.

Also, what is the o.d. of said bushing / bearing for the hole in the crank?

thanks

Attachments

Well thank you MarlinJack... So..... where did YOU get it?...lol...

And

Did you you buy it in bars and just bore it and touch it up or what?

Lay it on me ...

@marlinjack posted:

......The Crackshaft Bearing POCKET can get up to 300F-400F Degrees, I'am guessing here. The Steel Expands More than the Bronze. If One has followed Instructions and Cleaned out the Pocket "But don't Make it Larger!", or there has been corrosion, that was cleared out...the I.D. of the pocket will Be Larger than the 'Nominal' dimension of ONLY 1.3750"!!

......

Fake:

chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/https://psec.uchicago.edu/thermal_coefficients/cte_metals_05517-90143.pdf

Unless the University of Chicago is wrong ![]()

I am not and never have been a machining professional and I am sure you are much better than me at a lathe or a milling machine, but on the other hand, yes I have learned to define the right level of to be precise, this is the work of the engineers and the machinists only carry out what the engineers have determined.

No, I never served, I was lucky not to be one of the young people that our governments needlessly sacrificed, since USA, like France before you, lost the war against communism. But I respect veterans.

Attachments

Well, I hope that pissing contest is over.

Back to what this forum is about, people helping people.

So for the guys like me that are not Master mechanics, master welders, electricians, Machinist etc… Just average Shadetree mechanics that understand the limits of our knowledge and abilities that know when to seek help.

I hope guys continue to ask questions here and not be afraid that their question might sound stupid. Always better to ask a stupid question than make a stupid mistake. I’ve posted lots of questions and the brain trust here has always been very helpful without fail. For that I offer my deepest appreciation and thanks.

So, here’s my question, has anyone found out if any of the Pantera vendors sell a pilot bushing?

Ok, Back to the original post. Can anyone recommend a pilot bushing that we can buy today that would be the best we can buy today for our application in a Pantera? That is what I am looking for. Please help!

@marlinjack - Again since you do not make these anymore, that is why I am asking. the question. If you were still making them, I would buy one of yours. I just found one from Mcleod that I thought would be a good one that I could buy today. Any recommendations would be appreciated.

@panterapatt - Good idea. I will call the vendors to see what they recommend. I will also call Greg at Full Throttle Panteras and see what he uses.

Again, any recommendations would be greatly appreciated. Larry

You could also ask Ron McCall. He knows these more than all of us combined.

Since Marlin is no longer making them,

I would look for a NOS Ford bushing. It is originally what was used in the Pantera. That is what I use in all of mine.

C8AZ-7600-A.

I don't see any for sale at the moment but they are out there and they do turn up. The Dorman will work but as with Marlin's caution, the alloy of the material is important because of the ZF non-tempered input nose.

As a result you want to know the alloy used. Dorman isn't specifying it. With the Ford, you don't need to.

I have not checked with the clutch companies but I wouldn't be surprised if they did not know the answer to that?