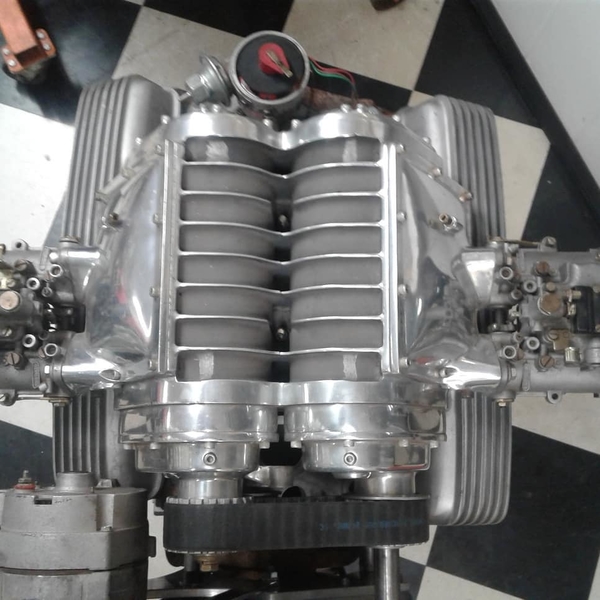

I've managed to source a New Old Stock Mgnecharger for a SBC. Its the low profile design for the Corvette and Camaro. This setup comes with the original dual Dellorto DHLA 40mm and lots of pulleys for various overdrive settings. I will need to upgrade the Dellorto 40mm to 48mm for my application but I am after people's opinions on how hard they've turned them and how efficient they are.

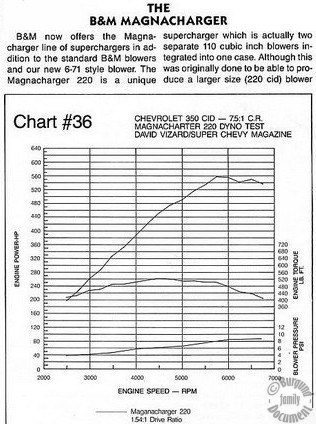

I am basically chasing any info I can get. I have spoken to Magnuson supercharger and he had a lot of positive things to say about them, so I am just seeing other peoples experiences. Anyone have any more info who has run the setup. What boost were the two MC110cu capable of producing and on what engine combo?

I found that the superchargers are mounted on an vintage Edelbrock street-master manifold. By the looks of it you can mount it on any single plain manifold providing you put the studs in... Also the rotors do not have Teflon strips..

Here are a few pictures. Anyone run this supercharger and can shed more light.

Original Post

Replies sorted oldest to newest

Here are my 48mm Dellorto ...

Here are my 48mm Dellorto ...